Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Retort Furnace Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

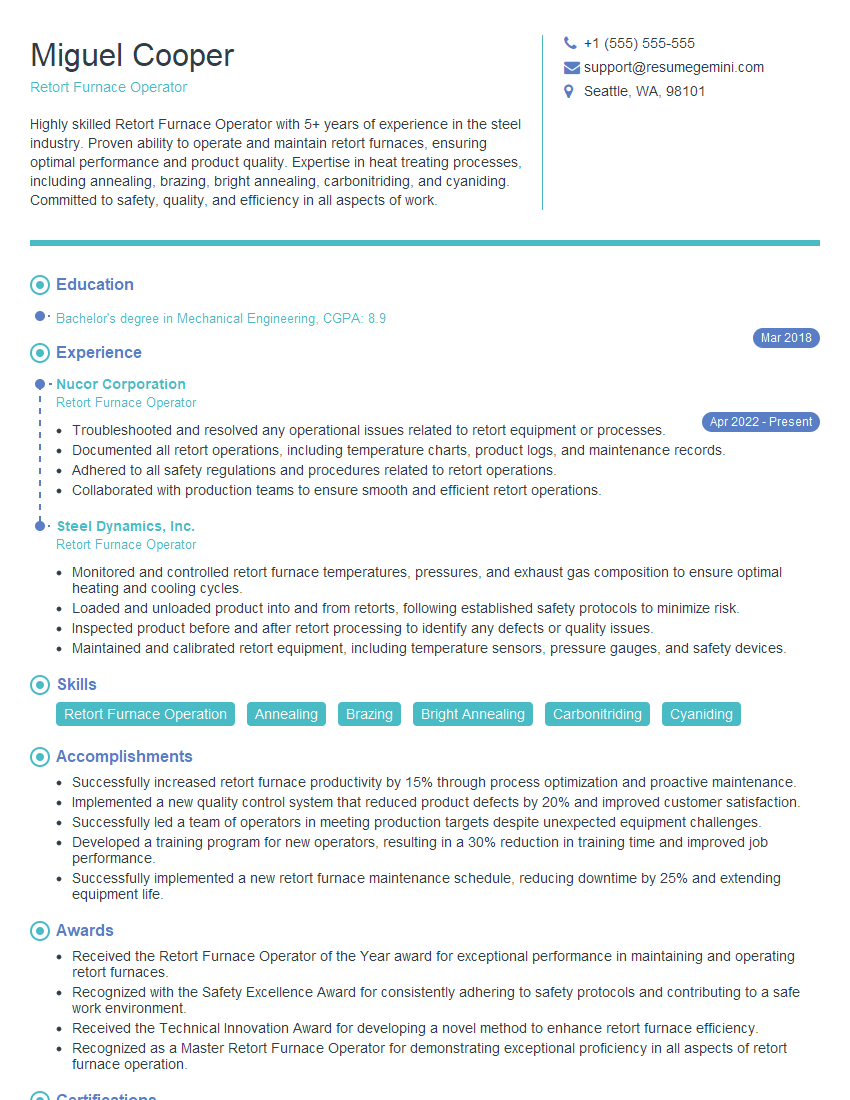

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Retort Furnace Operator

1. Describe the key responsibilities of a Retort Furnace Operator.

As a Retort Furnace Operator, my responsibilities include:

- Operating and maintaining retort furnaces to heat treat materials

- Monitoring and adjusting furnace temperatures, pressures, and other process parameters

- Loading and unloading materials into and out of the furnace

- Performing quality checks on finished products

- Maintaining a safe and clean work environment

2. Explain the different types of retort furnaces and their applications.

Types of Retort Furnaces

- Horizontal Retort Furnaces: Used for heat treating large or heavy workpieces

- Vertical Retort Furnaces: Used for heat treating smaller workpieces or those that require a controlled atmosphere

- Batch Retort Furnaces: Used for heat treating small batches of workpieces

- Continuous Retort Furnaces: Used for heat treating large volumes of workpieces

Applications

- Annealing: Softening metals by heating and cooling them slowly

- Hardening: Increasing the hardness of metals by heating and cooling them quickly

- Tempering: Reducing the brittleness of hardened metals by heating and cooling them at a controlled rate

- Stress relieving: Removing internal stresses in metals by heating and cooling them slowly

3. How do you ensure the safety of the retort furnace operation?

I follow strict safety protocols to ensure the safe operation of the retort furnace, including:

- Wearing appropriate personal protective equipment (PPE), including gloves, safety glasses, and a hard hat

- Inspecting the furnace and equipment before each use

- Following proper loading and unloading procedures

- Monitoring the furnace temperature and pressure closely

- Being aware of the potential hazards of the materials being heat treated

4. How do you troubleshoot common problems with retort furnaces?

I have experience troubleshooting common problems with retort furnaces, such as:

- Temperature fluctuations

- Pressure drops

- Material defects

- Equipment malfunctions

I use a systematic approach to troubleshooting, including:

- Identifying the problem

- Determining the cause of the problem

- Implementing a solution

- Verifying that the solution has resolved the problem

5. How do you maintain the retort furnace to ensure optimal performance?

I perform regular maintenance tasks to ensure optimal performance of the retort furnace, including:

- Lubricating moving parts

- Cleaning the furnace and equipment

- Inspecting the furnace for wear and tear

- Calibrating the furnace temperature and pressure gauges

- Performing preventive maintenance as recommended by the manufacturer

6. How do you handle hazardous materials used in retort furnace operations?

When handling hazardous materials used in retort furnace operations, I follow proper safety procedures, including:

- Wearing appropriate PPE

- Storing materials in a safe and secure location

- Following proper disposal procedures

- Being aware of the potential hazards of the materials

7. Explain the importance of quality control in retort furnace operations.

Quality control is essential in retort furnace operations to ensure that the heat treatment process meets the desired specifications. I perform quality checks on finished products to:

- Verify that the materials have been heat treated to the correct temperature and for the correct amount of time

- Ensure that the materials meet the desired hardness, strength, and other properties

- Identify any defects or non-conformances

8. How do you work effectively as part of a team?

I am a team player and I am able to work effectively with others to achieve common goals. I am good at communicating, collaborating, and sharing information. I am also willing to help others and I am always willing to learn from others.

9. What are your strengths and weaknesses as a Retort Furnace Operator?

Strengths

- Strong technical skills

- Attention to detail

- Safety-conscious

- Team player

- Problem solver

Weaknesses

- Sometimes I can be a bit too detail-oriented

- I am still learning about the different types of materials that can be heat treated

10. Why are you interested in this position?

I am interested in this position because I am looking for a challenging and rewarding career in the manufacturing industry. I am confident that my skills and experience would make me a valuable asset to your team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Retort Furnace Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Retort Furnace Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Retort Furnace Operator is responsible for the daily operation and maintenance of retort furnaces. They must possess a thorough knowledge of the furnace’s operations, as well as the safety procedures associated with its use.

1. Furnace Operations

The operator is responsible for ensuring the correct operation of the retort furnace at all times.

- Prepare and load the furnace with materials.

- Monitor the furnace temperature and adjust it as necessary.

2. Furnace Maintenance

In addition to operating the furnace, the operator is also responsible for performing routine maintenance and repairs.

- Maintain and clean the furnace and its components.

- Inspect the furnace regularly for any signs of damage or wear.

3. Safety Procedures

Retort furnaces can be hazardous, so it is essential that the operator follows all safety procedures.

- Wear appropriate personal protective equipment.

- Follow all lockout/tagout procedures.

4. Quality Control

The retort furnace operator is also responsible for ensuring the quality of the finished product.

- Inspect the finished product for any defects.

- Keep records of all furnace operations and maintenance.

Interview Tips

Preparing for an interview for a position as a Retort Furnace Operator can be daunting, but by following these tips, you can increase your chances of success.

1. Research the company and the position.

Take some time to learn about the company you’re applying to and the specific position you’re interested in. This will help you understand the company’s culture and the skills and experience that they are looking for.

- Visit the company’s website and social media pages.

- Read articles and reviews about the company.

2. Practice answering common interview questions.

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice answering these questions in advance so that you can deliver your responses confidently and concisely.

- Use the STAR method to answer behavioral questions.

- Tailor your answers to the specific job you’re applying for.

3. Bring a copy of your resume and references.

Make sure you bring a copy of your resume and a list of references to the interview. This will allow the interviewer to review your qualifications and contact your references if they have any questions.

- Highlight your skills and experience that are most relevant to the position.

- Include contact information for your references.

4. Dress professionally and be on time.

First impressions matter, so make sure you dress professionally and arrive for your interview on time. This will show the interviewer that you are serious about the position and that you respect their time.

- Choose clothing that is appropriate for the company culture.

- Give yourself plenty of time to get to the interview location.

Next Step:

Now that you’re armed with the knowledge of Retort Furnace Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Retort Furnace Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini