Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Rotary Furnace Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

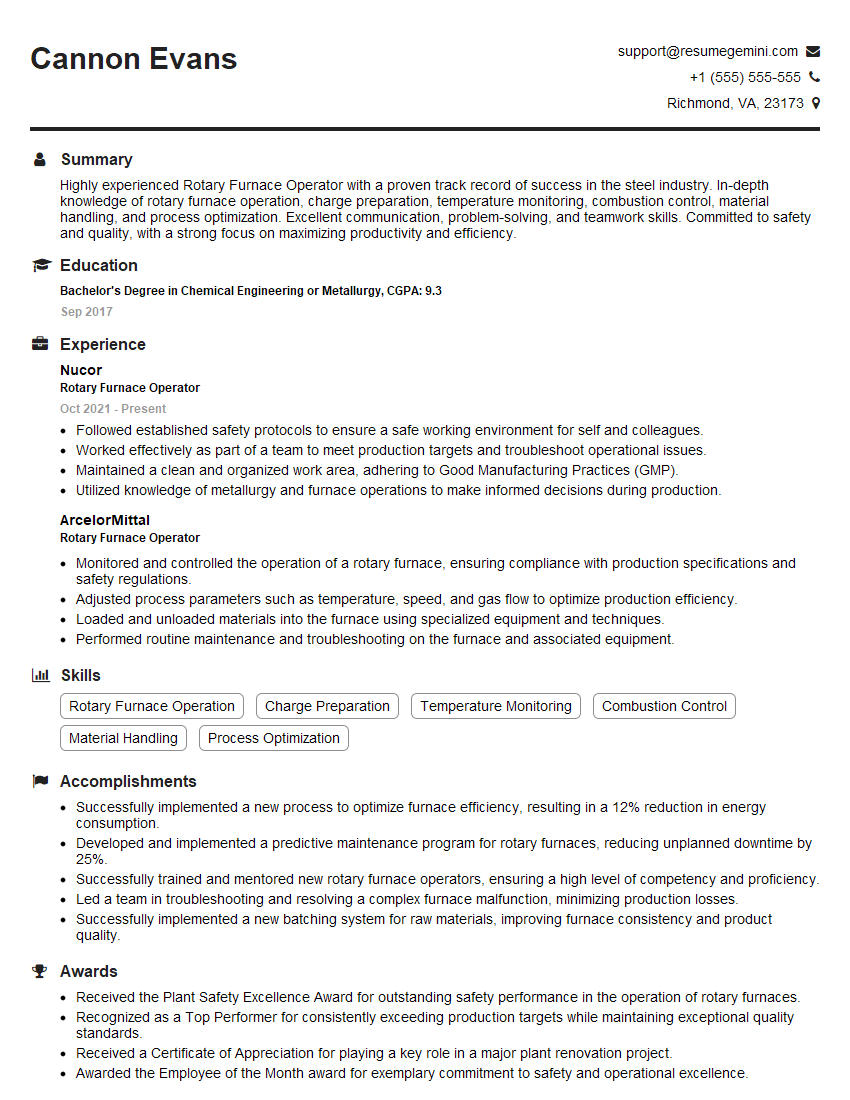

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rotary Furnace Operator

1. Explain the process of charging the rotary furnace?

The process of charging a rotary furnace involves several steps:

- Preheating the furnace: Before charging, the furnace is preheated to a specific temperature to ensure proper melting and avoid thermal shock.

- Loading the feedstock: The feedstock, which can be metal scraps, minerals, or other materials, is loaded into the furnace using a charging bucket or conveyor.

- Melting and mixing: As the furnace rotates, the feedstock is heated and melted. The rotation also helps mix the materials to ensure homogeneity.

- Monitoring and adjustments: During charging, the operator monitors the temperature, feed rate, and other parameters to ensure optimal conditions for melting and mixing.

2. Describe the key operational parameters of a rotary furnace?

Temperature control

- Temperature is crucial in rotary furnace operation, as it affects the melting process, product quality, and furnace longevity.

- Operators monitor and adjust temperatures using thermocouples or pyrometers, ensuring they stay within specified ranges.

Feed rate

- The feed rate determines the amount of material charged into the furnace per unit time.

- Adjusting the feed rate helps control the melting rate, furnace efficiency, and product yield.

Rotation speed

- The rotation speed of the furnace affects material mixing, melting, and heat transfer.

- Optimizing the speed ensures proper melting, minimizes wear on the furnace lining, and improves energy efficiency.

Atmosphere control

- In certain rotary furnace applications, controlling the atmosphere inside the furnace is essential for product quality and furnace performance.

- Operators may use inert gases or reducing agents to maintain the desired atmosphere.

3. What are the common problems encountered in rotary furnace operation and how do you address them?

Common problems in rotary furnace operation include:

- Uneven heating: Address by optimizing burner placement, temperature monitoring, and feed distribution.

- Slag formation: Minimize by controlling temperature, feedstock composition, and using fluxing agents.

- Refractory wear: Monitor refractory condition, optimize furnace operation, and perform regular maintenance.

- Mechanical issues: Conduct regular inspections, perform preventive maintenance, and have spare parts readily available.

4. How do you ensure the safety of the rotary furnace operation?

To ensure safety in rotary furnace operation, several measures are taken:

- Proper training: Operators are thoroughly trained on safe operation procedures and emergency protocols.

- Personal protective equipment: Operators wear appropriate PPE, such as heat-resistant clothing, gloves, and eye/face protection.

- Regular inspections: Frequent inspections of the furnace, equipment, and work area are conducted to identify and address any potential hazards.

- Emergency response plans: Clear and detailed emergency response plans are in place to handle incidents such as gas leaks, fires, or equipment failures.

5. What is the significance of refractory lining in rotary furnaces?

The refractory lining in rotary furnaces is crucial for several reasons:

- Heat insulation: Refractory lining insulates the furnace shell, preventing heat loss and maintaining efficient operation.

- Chemical resistance: Refractory materials resist chemical reactions with the molten material, protecting the furnace shell and preventing contamination.

- Thermal stability: Refractory lining can withstand high temperatures and thermal cycling without degrading, ensuring furnace longevity.

- Maintenance and repair: Proper maintenance and timely repairs of the refractory lining are essential to prevent costly failures and extend furnace life.

6. How do you optimize the energy efficiency of a rotary furnace?

Optimizing energy efficiency in rotary furnaces involves several techniques:

- Insulation: Proper insulation of the furnace shell and refractory lining reduces heat loss.

- Burner optimization: Efficient burners ensure complete combustion, reducing fuel consumption.

- Heat recovery systems: Recuperators or regenerators can capture waste heat from exhaust gases and preheat combustion air.

- Process optimization: Optimizing feedstock composition, furnace temperature, and rotation speed can improve energy efficiency.

- Regular maintenance: Proper maintenance of equipment, including bearings, seals, and burners, minimizes energy losses.

7. Describe the role of instrumentation and control systems in rotary furnace operation?

Instrumentation and control systems play a vital role in rotary furnace operation:

- Temperature monitoring: Thermocouples or pyrometers measure and control furnace temperature precisely.

- Feed rate control: Automated systems ensure the feedstock is charged at the desired rate.

- Rotation speed regulation: Variable frequency drives (VFDs) control the rotation speed of the furnace.

- Atmosphere monitoring: Sensors monitor and control the atmosphere inside the furnace, ensuring optimal conditions.

- Safety systems: Interlocks and alarms provide additional safety features, such as preventing furnace operation with insufficient gas flow or overheating.

8. What environmental considerations are important in rotary furnace operation?

Environmental considerations in rotary furnace operation include:

- Air pollution control: Baghouses or electrostatic precipitators collect particulate emissions.

- Water management: Wastewater treatment systems handle runoff and cooling water.

- Energy efficiency: Optimizing energy usage reduces greenhouse gas emissions.

- Waste management: Proper disposal of refractory lining and other furnace waste is essential.

- Noise control: Noise barriers or enclosures minimize noise pollution.

9. How do you troubleshoot and resolve common issues in rotary furnace operation?

Troubleshooting and resolving common issues in rotary furnace operation involve:

- Identifying the root cause: Analyze symptoms and potential causes to determine the source of the problem.

- Consulting documentation: Refer to operating manuals, maintenance records, and technical specifications for guidance.

- Using diagnostic tools: Employ instruments and sensors to gather data and identify specific issues.

- Implementing corrective actions: Based on the diagnosis, implement appropriate measures to resolve the issue.

- Verifying and testing: Test the furnace operation after repairs or adjustments to ensure the issue is resolved.

10. How do you maintain and ensure the longevity of a rotary furnace?

Maintaining and ensuring the longevity of a rotary furnace involves several practices:

- Preventive maintenance: Regular inspections, lubrication, and component replacements prevent breakdowns.

- Refractory inspection and repair: Inspect and repair the refractory lining to maintain its integrity and prevent heat loss.

- Burner maintenance: Keep burners clean and calibrated to ensure efficient combustion.

- Mechanical integrity: Monitor bearings, gears, and other mechanical components for wear and tear.

- Spare parts management: Maintain an inventory of critical spare parts to minimize downtime in case of failures.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rotary Furnace Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rotary Furnace Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rotary Furnace Operators are responsible for the safe and efficient operation of rotary furnaces used in various industries, such as metal casting, forging, and heat treatment. Their key responsibilities include:

1. Equipment Management

Operate and maintain rotary furnaces, ensuring they function optimally.

- Monitor furnace temperature, pressure, and other parameters.

- Adjust settings and make necessary repairs to maintain furnace efficiency.

2. Material Handling

Load and unload materials into and out of the furnace.

- Ensure proper material flow to optimize heating processes.

- Inspect materials for defects or damage before and after processing.

3. Quality Assurance

Monitor and control the quality of materials processed in the furnace.

- Conduct visual inspections and use testing equipment to ensure products meet specifications.

- Document and maintain records of furnace operations and quality control measures.

4. Safety and Maintenance

Adhere to safety protocols and perform routine maintenance to ensure a safe work environment.

- Wear appropriate personal protective equipment (PPE) and follow safety guidelines.

- Identify potential hazards and implement measures to mitigate risks.

- Perform preventive maintenance tasks, such as cleaning, lubrication, and inspection, to prevent breakdowns and extend equipment life.

Interview Tips

To prepare for an interview for a Rotary Furnace Operator position, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products or services, and industry trends. This will help you understand their operations and demonstrate your interest in the role.

2. Practice Common Interview Questions

Prepare answers to common interview questions, such as:

- Tell me about your experience in operating rotary furnaces.

- Describe a situation where you faced a challenge or problem while operating a furnace and how you resolved it.

3. Highlight Your Skills and Experience

Emphasize your technical skills, including knowledge of furnace operation, material handling, and quality control processes. Share specific examples of your experience that demonstrate your abilities.

4. Show Your Safety Consciousness

Explain your understanding of safety protocols and your commitment to maintaining a safe work environment. Discuss any safety initiatives or programs you have implemented or participated in.

5. Prepare Questions for the Interviewer

Asking informed questions at the end of the interview shows your engagement and interest. Examples include:

- What are the current production targets and how are they monitored?

- What opportunities are there for professional development and advancement within the company?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rotary Furnace Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!