Are you gearing up for a career in Iron Pourer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Iron Pourer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

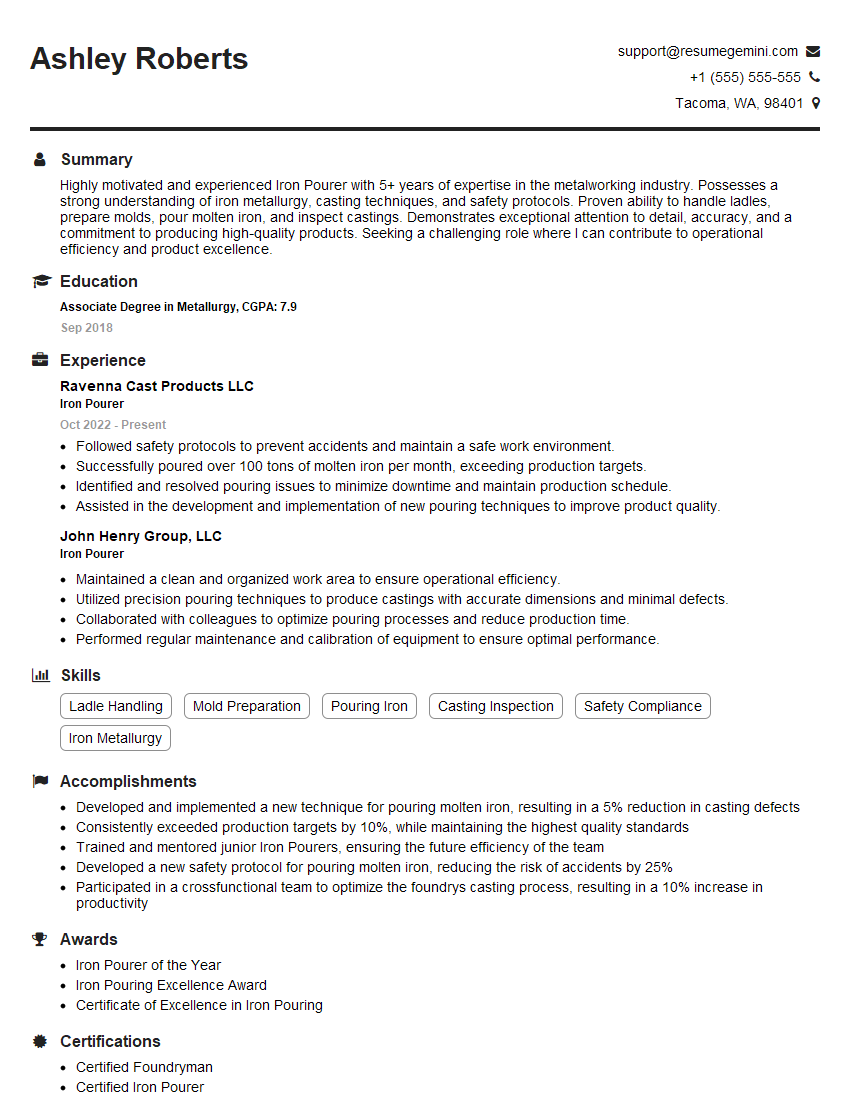

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Iron Pourer

1. What are the different types of iron castings?

- Gray iron castings

- White iron castings

- Malleable iron castings

- Ductile iron castings

2. What are the different processes used for iron casting?

Sand casting

- Sand casting is a process in which molten iron is poured into a sand mold and allowed to solidify.

- The sand mold is made by packing sand around a pattern, which is a replica of the desired casting.

Die casting

- Die casting is a process in which molten iron is forced under high pressure into a metal die, which is a replica of the desired casting.

- Die casting produces castings with a high degree of precision and surface finish.

Investment casting

- Investment casting is a process in which a wax pattern is coated with a refractory material and then invested in a ceramic mold.

- The wax pattern is then melted out, and molten iron is poured into the mold.

Centrifugal casting

- Centrifugal casting is a process in which molten iron is poured into a spinning mold.

- The centrifugal force causes the molten iron to be distributed evenly around the mold, producing a casting with a uniform wall thickness.

3. What are the key factors that affect the quality of iron castings?

- The composition of the iron

- The melting temperature

- The pouring temperature

- The cooling rate

- The mold design

4. What are the common defects that can occur in iron castings?

- Shrinkage defects

- Gas defects

- Inclusion defects

- Molding defects

- Casting defects

5. How can defects in iron castings be prevented?

- Proper melting practices

- Proper mold design

- Proper pouring practices

- Proper cooling practices

- Proper inspection and testing procedures

6. What are the different methods used to finish iron castings?

- Grinding

- Polishing

- Buffing

- Plating

- Painting

7. What are the safety precautions that must be taken when working with iron castings?

- Wear appropriate protective clothing, including gloves, safety glasses, and a hard hat.

- Use proper lifting techniques to avoid injury.

- Be aware of the hazards of molten metal and avoid contact with it.

- Keep the work area clean and free of debris.

- Follow all safety procedures and regulations.

8. What is the role of an iron pourer?

- To operate the pouring furnace

- To control the temperature of the molten iron

- To pour the molten iron into the molds

- To inspect the castings for defects

- To maintain the pouring equipment

9. What are the qualifications for an iron pourer?

- A high school diploma or equivalent

- Experience in a foundry setting

- Knowledge of the iron pouring process

- Ability to read and interpret blueprints

- Good communication and interpersonal skills

10. What are the career opportunities for an iron pourer?

- Promotion to supervisor or manager

- Work as a quality control inspector

- Start your own foundry business

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Iron Pourer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Iron Pourer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Iron Pourers, also known as Tappers, play a crucial role in foundries, operating and maintaining equipment involved in pouring molten iron into molds.

1. Equipment Operation and Maintenance

Iron Pourers are responsible for ensuring the smooth operation and proper maintenance of melting furnaces, holding ladles, and casting equipment. They operate and control these machines to produce molten iron at the desired temperature and composition.

- Operate melting furnaces to melt iron scrap and alloys to create molten iron.

- Control and adjust furnace temperature and composition to meet specifications.

- Maintain, repair, and clean equipment to ensure optimal performance.

2. Iron Pouring and Molding

Iron Pourers are responsible for pouring molten iron into molds and ladles, ensuring that castings meet specifications. They use various techniques and equipment to control the pour rate, temperature, and flow of molten iron.

- Prepare molds and ladles for pouring by applying coatings and checking for defects.

- Control the flow and temperature of molten iron to ensure proper filling and casting.

- Monitor and adjust casting parameters to optimize production yield.

3. Safety and Quality Control

Iron Pourers must adhere to strict safety protocols and quality control measures to ensure their own safety and the quality of castings. They follow established procedures, wear protective gear, and monitor equipment to maintain a safe work environment.

- Follow safety protocols and wear protective gear, including heat-resistant clothing, gloves, and face shields.

- Inspect castings for defects and monitor quality control parameters.

- Maintain a clean and organized work area to prevent accidents and spills.

4. Collaboration and Communication

Iron Pourers work closely with other foundry personnel, including melters, molders, and inspectors. They communicate effectively to coordinate pouring schedules, discuss casting requirements, and resolve any production issues.

- Collaborate with melters to ensure that molten iron is ready for pouring.

- Communicate with molders to discuss casting requirements and mold preparation.

- Provide feedback to inspectors regarding casting quality and any potential issues.

Interview Tips

Preparing thoroughly for an Iron Pourer interview can significantly increase your chances of success. Here are some valuable tips and tricks to help you ace the interview:

1. Research the Company and Position

Learn about the foundry’s history, products, and industry standing. Understand the specific job requirements and responsibilities of an Iron Pourer within the organization. This knowledge demonstrates your interest in the position and the company.

- Visit the company website to gather information about their operations, products, and recent news.

- Review the job description thoroughly to identify the key responsibilities and qualifications required.

- Research industry trends and best practices to demonstrate your knowledge of the field.

2. Highlight Your Skills and Experience

Emphasize your technical skills in operating and maintaining iron pouring equipment. Quantify your accomplishments and provide specific examples of how you have contributed to production efficiency or quality improvement.

- Describe your experience in operating melting furnaces, holding ladles, and casting equipment.

- Quantify your achievements in terms of increased productivity, reduced waste, or improved casting quality.

- Share examples of your ability to troubleshoot and resolve equipment issues.

3. Demonstrate Safety and Quality Consciousness

Safety is paramount in foundries. Emphasize your understanding of safety protocols and your commitment to maintaining a safe work environment. Highlight your knowledge of quality control measures and your ability to produce castings that meet specifications.

- Describe your experience in following safety protocols and wearing protective gear.

- Explain your understanding of quality control procedures and your ability to identify and rectify casting defects.

- Share examples of your contributions to improving casting quality or reducing scrap rates.

4. Practice and Prepare Questions

Practice your answers to common interview questions. Anticipate questions related to your technical skills, experience, safety consciousness, and problem-solving abilities. Prepare thoughtful questions to ask the interviewer, demonstrating your interest in the position and the company.

- Practice answering questions about your equipment operation and maintenance experience.

- Prepare examples of how you have handled challenges or resolved problems in a foundry setting.

- Ask questions about the company’s safety protocols, quality control measures, and training opportunities.

5. Dress Professionally and Arrive Punctually

First impressions matter. Dress professionally and arrive for your interview on time. A neat and well-presented appearance demonstrates your respect for the interviewer and the company.

- Wear business attire, such as slacks, a button-down shirt, and closed-toe shoes.

- Arrive for your interview at least 10 minutes early to show that you value punctuality.

- Maintain a professional demeanor throughout the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Iron Pourer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!