Are you gearing up for a career in Ladle Pourer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Ladle Pourer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

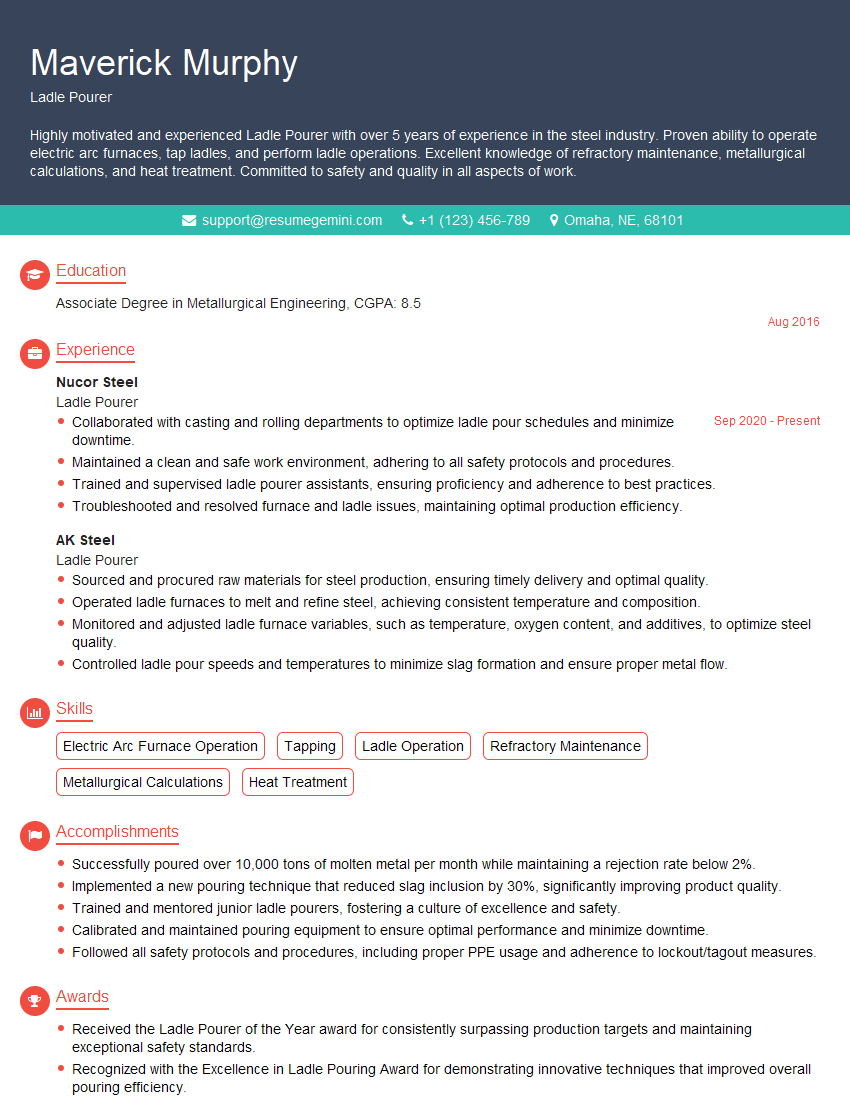

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ladle Pourer

1. Describe the process of preparing the ladle for pouring.

The process of preparing the ladle for pouring involves several important steps to ensure smooth and efficient operation:

- Preheat the Ladle: The ladle is heated to a specific temperature before use to prevent thermal shock and ensure proper metal flow.

- Lubricate the Ladle: The ladle’s interior is coated with a lubricant to reduce friction between the molten metal and the ladle.

- Inspect the Ladle: The ladle is visually inspected before pouring to check for any damage or defects that could affect its integrity.

2. What factors should be considered when determining the pouring height?

Optimizing Pouring Height

- Metal Flow Rate: The desired flow rate of the molten metal influences the pouring height.

- Ladle Nozzle Size: The diameter of the ladle nozzle affects the stream of molten metal.

- Metal Temperature: The temperature of the molten metal can impact its viscosity and flow.

- Mold Size and Geometry: The dimensions and shape of the mold affect the pouring height.

Safety Considerations

- Overhead Obstacles: The height should ensure clearance from any overhead equipment or structures.

- Splashing and Heat Exposure: Proper height minimizes splashing and reduces the risk of burns to operators.

3. How do you ensure the safety of the pouring process?

Ensuring the safety of the pouring process is paramount:

- Personal Protective Equipment: Using appropriate PPE (gloves, apron, safety glasses, and helmet) protects against burns and splashes.

- Adequate Ventilation: Good ventilation removes fumes and prevents buildup of hazardous gases.

- Proper Training: Operators are thoroughly trained on safe pouring practices and emergency procedures.

- Regular Maintenance: Equipment is regularly inspected and maintained to prevent malfunctions.

- Emergency Response Plan: A clear and effective plan is in place to respond to any accidents or incidents.

4. What are the common problems you encounter during pouring, and how do you resolve them?

Common problems and their resolutions during pouring include:

- Clogged Nozzle: Use a metal rod or wire to clear the nozzle and ensure a smooth metal flow.

- Metal Sticking to the Ladle: Increase the lubrication of the ladle or adjust the pouring temperature.

- Insufficient Pouring Height: Adjust the height to ensure proper metal flow and avoid splashing.

- Excessive Splashing: Reduce the pouring height, increase the lubricant, or modify the nozzle size.

- Metal Spills: Immediately notify the supervisor and follow established emergency procedures.

5. How do you maintain the quality of the molten metal during pouring?

Maintaining the quality of the molten metal during pouring is crucial:

- Temperature Control: Monitor and adjust the temperature during pouring to prevent premature solidification or excessive heat loss.

- Flux Usage: Use appropriate fluxes to remove impurities and improve metal flow.

- Stirring and Degassing: Stirring and degassing remove gases and enhance metal homogeneity.

- Proper Pouring Technique: Minimizing turbulence and oxidation during pouring preserves metal quality.

6. Describe the different types of ladles used in metal pouring and their specific applications.

Types of Ladles

- Hand Ladles: Small, hand-operated ladles for precise pouring in small quantities.

- Lip-Pour Ladles: Tilting ladles with a lip for pouring into molds or crucibles.

- Bottom-Pour Ladles: Ladles with a stopper at the bottom, allowing controlled pouring and minimizing splashing.

- Tundish Ladles: Large ladles used in continuous casting processes, holding molten metal for extended periods.

Applications

- Foundries: Pouring molten metal into molds to create castings.

- Steel Mills: Handling and distributing molten steel in various processes.

- Refineries: Transferring and casting molten metals during refining operations.

7. How do you estimate the amount of molten metal required for a specific casting?

Estimating the amount of molten metal required involves several considerations:

- Casting Dimensions: Calculate the volume of the casting using its dimensions.

- Metal Density: Determine the density of the metal being poured.

- Casting Yield: Factor in the yield percentage to account for metal losses during casting.

- Ladle Capacity: Consider the capacity of the ladle used for pouring.

8. Explain how you handle and store ladles safely.

Handling

- Use Proper Lifting Equipment: Utilize cranes or forklifts to move heavy ladles safely.

- Wear Protective Gear: Wear appropriate PPE, including gloves and safety glasses.

- Avoid Sudden Movements: Handle ladles carefully to prevent spills or accidents.

Storage

- Designated Storage Area: Store ladles in designated, well-ventilated areas.

- Level Surface: Place ladles on level surfaces to prevent tipping.

- Proper Support: Use supporting blocks or stands to prevent damage to the ladle.

9. What measures do you take to reduce the risk of slag inclusions in the poured metal?

- Flux Usage: Use appropriate fluxes to remove impurities and create a protective layer on the molten metal.

- Skimming: Regularly skim the slag from the surface of the molten metal before pouring.

- Proper Pouring Technique: Pour carefully to minimize turbulence and prevent slag from entering the mold.

- Ladle Preparation: Ensure the ladle is clean and free of slag before pouring.

10. How do you calculate the pouring rate to achieve a desired filling time?

Calculating the pouring rate involves the following steps:

- Determine Volume: Calculate the volume of the mold that needs to be filled.

- Estimate Filling Time: Determine the desired filling time based on process parameters or customer requirements.

- Calculate Pouring Rate: Divide the volume of the mold by the filling time to obtain the required pouring rate.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ladle Pourer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ladle Pourer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Ladle Pourer is responsible for pouring molten metal from a ladle into molds or other containers in a foundry.

1. Ladle Preparation

Preparing the ladle for use, inspecting for damage, and ensuring it is properly lined and pre-heated.

- Inspecting the ladle for cracks, damage, or leaks

- Ensuring the ladle is properly lined with refractory material

- Pre-heating the ladle to prevent the metal from freezing

2. Metal Handling

Receiving molten metal from the furnace, handling it safely, and pouring it accurately into molds.

- Receiving molten metal from the furnace using tongs or other tools

- Transporting the molten metal to the pouring area

- Pouring the molten metal into molds or other containers

3. Ladle Maintenance

Cleaning and maintaining the ladle, ensuring it is in good working condition.

- Cleaning the ladle after each use to remove slag and other debris

- Inspecting the ladle regularly for damage or wear

- Performing minor repairs on the ladle as needed

4. Safety Practices

Following all safety regulations and using appropriate equipment to prevent accidents.

- Wearing proper protective clothing and equipment, including heat-resistant gloves, apron, and face shield

- Using tongs or other tools to handle molten metal safely

- Following all safety procedures and regulations

Interview Tips

To ace the interview for a Ladle Pourer position, it’s crucial to prepare thoroughly. Here are some tips:

1. Research the Company and Role

Familiarize yourself with the company’s history, operations, and the specific responsibilities of the Ladle Pourer role. This demonstrates your interest and enthusiasm for the position.

- Visit the company website to learn about their products, services, and culture

- Look for news articles or industry reports about the company to stay updated on recent developments

- Read the job description carefully to understand the key responsibilities and qualifications required

2. Highlight Relevant Skills and Experience

Emphasize your strengths and abilities that align with the requirements of the Ladle Pourer role. Quantify your accomplishments whenever possible to showcase your impact.

- Describe your experience in handling molten metal, including any specific techniques or equipment you have used

- Highlight your knowledge of safety regulations and procedures related to foundry operations

- Mention any relevant certifications or training programs you have completed

3. Prepare for Technical Questions

You should expect to face technical questions during the interview. Practice answering questions about:

- The properties of molten metal and how to handle it safely

- The different types of ladles used in foundries and their applications

- Common safety hazards associated with molten metal handling and how to mitigate them

4. Dress Professionally and Be on Time

First impressions matter. Dress professionally and arrive on time for your interview. This shows that you are respectful of the interviewer and the opportunity.

- Choose clothing that is clean, pressed, and appropriate for a foundry environment

- Arrive at the interview location at least 15 minutes early to allow for any unexpected delays

- Greet the interviewer with a firm handshake and make eye contact

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ladle Pourer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!