Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Jig and Fixture Builder interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Jig and Fixture Builder so you can tailor your answers to impress potential employers.

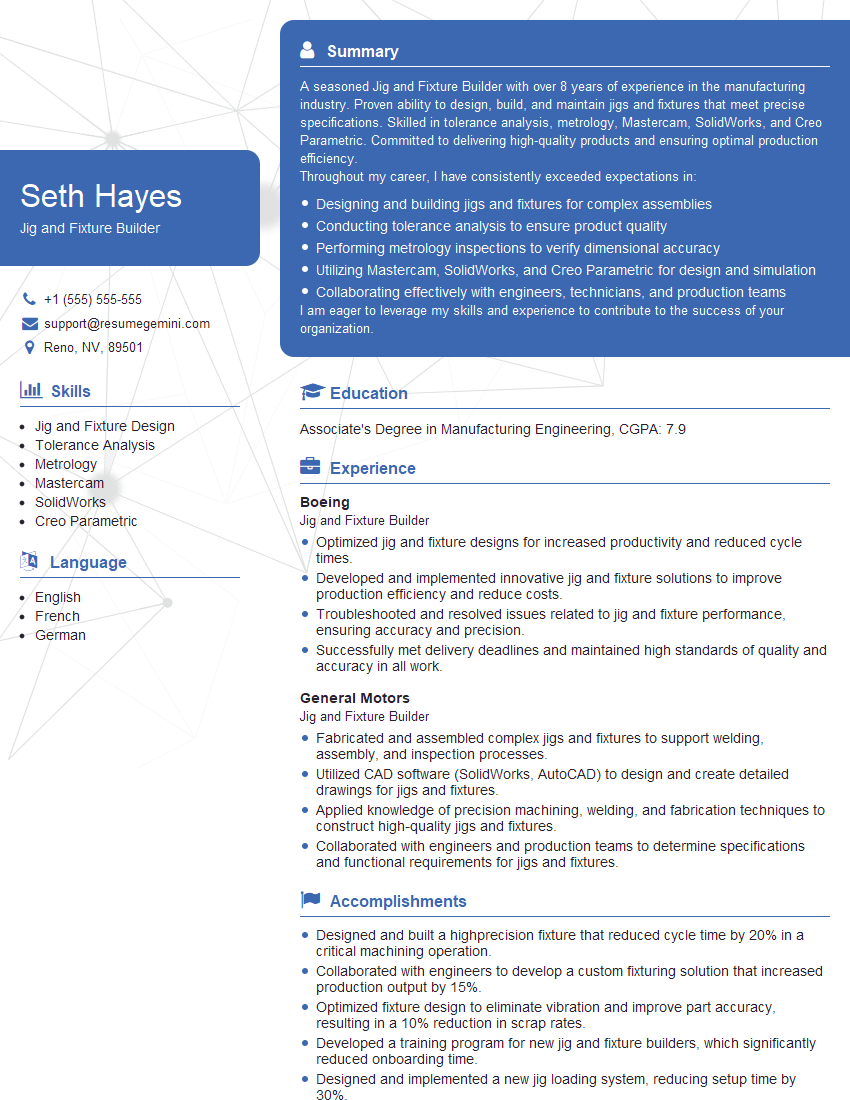

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Jig and Fixture Builder

1. What are the key considerations when designing a jig or a fixture?

When designing a jig or fixture, the following key considerations must be taken into account:

- Workpiece: The size, shape, and material of the workpiece will determine the type of jig or fixture required.

- Operation: The operation that will be performed on the workpiece will also determine the design of the jig or fixture.

- Accuracy: The required accuracy of the operation will determine the precision of the jig or fixture.

- Cost: The cost of the jig or fixture must be taken into account.

2. What are the different types of jigs and fixtures?

There are many different types of jigs and fixtures, but some of the most common include:

Drill jigs

- Used to guide drill bits and ensure accurate hole placement.

- Can be simple or complex, and may incorporate features such as bushings, stops, and clamps.

Welding fixtures

- Used to hold workpieces in place during welding operations.

- Typically made of heavy-duty materials and may include features such as clamps, locators, and supports.

Assembly fixtures

- Used to hold workpieces in place during assembly operations.

- May incorporate features such as guides, locators, and clamps to ensure accurate assembly.

Inspection fixtures

- Used to hold workpieces in place during inspection operations.

- May incorporate features such as gauges, probes, and lighting to facilitate inspection.

3. What are the materials used to make jigs and fixtures?

The materials used to make jigs and fixtures vary depending on the application, but some of the most common include:

- Steel: Steel is a strong and durable material that is often used for jigs and fixtures that require high precision.

- Aluminum: Aluminum is a lightweight and corrosion-resistant material that is often used for jigs and fixtures that require portability.

- Plastic: Plastic is a low-cost and lightweight material that is often used for jigs and fixtures that are used for low-volume production.

- Wood: Wood is a low-cost and easy-to-work material that is often used for jigs and fixtures that are used for prototyping or short-run production.

4. What are the advantages of using jigs and fixtures?

There are many advantages to using jigs and fixtures, including:

- Increased accuracy: Jigs and fixtures can help to ensure that workpieces are accurately positioned and held in place, resulting in improved accuracy of the finished product.

- Increased productivity: Jigs and fixtures can help to speed up production by reducing the amount of time required to set up and perform operations.

- Reduced costs: Jigs and fixtures can help to reduce costs by reducing scrap and rework, and by increasing productivity.

- Improved safety: Jigs and fixtures can help to improve safety by reducing the risk of accidents and injuries.

5. What are the challenges of designing and building jigs and fixtures?

There are a number of challenges associated with designing and building jigs and fixtures, including:

- Complexity: Jigs and fixtures can be complex to design and build, especially for complex workpieces or operations.

- Precision: Jigs and fixtures must be precise in order to ensure accurate results.

- Cost: Jigs and fixtures can be expensive to design and build.

- Maintenance: Jigs and fixtures require regular maintenance to ensure that they continue to perform accurately.

6. What are the latest trends in jig and fixture design?

Some of the latest trends in jig and fixture design include:

- Use of 3D printing: 3D printing is increasingly being used to create jigs and fixtures, as it allows for the rapid prototyping and production of complex designs.

- Use of lightweight materials: Lightweight materials, such as aluminum and carbon fiber, are increasingly being used in jig and fixture design to reduce weight and improve portability.

- Use of modular design: Modular design allows jigs and fixtures to be easily reconfigured to accommodate different workpieces or operations.

- Use of automation: Automation is increasingly being used in jig and fixture design to improve productivity and accuracy.

7. What are the key quality control checks that should be performed on jigs and fixtures?

The following key quality control checks should be performed on jigs and fixtures:

- Dimensional accuracy: The dimensions of the jig or fixture should be checked to ensure that they meet the specified requirements.

- Material quality: The material used to make the jig or fixture should be inspected to ensure that it meets the specified requirements.

- Workmanship: The workmanship of the jig or fixture should be inspected to ensure that it is of high quality.

- Performance testing: The jig or fixture should be tested to ensure that it performs as intended.

8. What are the safety precautions that should be taken when using jigs and fixtures?

The following safety precautions should be taken when using jigs and fixtures:

- Wear appropriate safety gear: When using jigs and fixtures, it is important to wear appropriate safety gear, such as safety glasses, gloves, and a hard hat.

- Inspect jigs and fixtures before use: Before using a jig or fixture, it is important to inspect it for any damage or defects.

- Use jigs and fixtures properly: Jigs and fixtures should be used properly in accordance with the manufacturer’s instructions.

- Be aware of pinch points: Be aware of any pinch points on jigs and fixtures and avoid getting your hands or fingers caught.

9. What are the most common problems that can occur with jigs and fixtures?

Some of the most common problems that can occur with jigs and fixtures include:

- Wear and tear: Jigs and fixtures can wear out over time, which can lead to reduced accuracy and performance.

- Damage: Jigs and fixtures can be damaged by improper use or handling.

- Misalignment: Jigs and fixtures can become misaligned over time, which can lead to reduced accuracy and performance.

- Corrosion: Jigs and fixtures can corrode over time, which can lead to reduced accuracy and performance.

10. What are the maintenance procedures that should be followed for jigs and fixtures?

The following maintenance procedures should be followed for jigs and fixtures:

- Regular cleaning: Jigs and fixtures should be cleaned regularly to remove any dirt or debris that may build up.

- Regular inspection: Jigs and fixtures should be inspected regularly for any damage or wear and tear.

- Regular lubrication: Jigs and fixtures should be lubricated regularly to ensure that they move smoothly and accurately.

- Regular calibration: Jigs and fixtures should be calibrated regularly to ensure that they are accurate.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Jig and Fixture Builder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Jig and Fixture Builder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Jig and Fixture Builders play a pivotal role in ensuring precision and efficiency in manufacturing processes. Their primary responsibilities include:

1. Design and Fabrication

Analyze product designs, specifications, and manufacturing requirements to create blueprints and specifications for jigs and fixtures.

- Select appropriate materials, components, and manufacturing techniques based on functional requirements.

- Utilize computer-aided design (CAD) and other software to develop detailed drawings and models.

2. Assembly and Testing

Assemble, align, and test jigs and fixtures according to design specifications.

- Ensure accuracy and precision by utilizing precision measuring tools and techniques.

- Conduct rigorous testing to validate performance and identify any potential issues.

3. Installation and Training

Install and calibrate jigs and fixtures on production equipment.

- Provide training to operators on the proper use and maintenance of jigs and fixtures.

- Monitor performance and make necessary adjustments to optimize manufacturing processes.

4. Maintenance and Repair

Perform preventive maintenance and repairs on jigs and fixtures to ensure optimal operation.

- Troubleshoot and diagnose problems, identifying and replacing worn or damaged components.

- Maintain inventory of spare parts and materials to minimize downtime.

Interview Tips

By following these tips, candidates can significantly enhance their chances of success in a Jig and Fixture Builder interview:

1. Research the Company and Role

Thoroughly research the company, their products, and the specific role requirements.

- Gain insights into the company’s industry, culture, and manufacturing processes.

- Identify specific skills and experiences that align with the job description.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in core competencies required for the job.

- Showcase your ability in CAD, design, fabrication, and testing of jigs and fixtures.

- Quantify your accomplishments by providing specific examples of projects handled.

3. Demonstrate Problem-Solving Abilities

Provide examples that highlight your problem-solving skills in designing, troubleshooting, or optimizing jigs and fixtures.

- Describe situations where you identified and resolved issues with precision and efficiency.

- Emphasize your ability to analyze, troubleshoot, and develop solutions.

4. Ask Thoughtful Questions

Prepare thoughtful questions to demonstrate your interest and engagement.

- Inquire about the company’s manufacturing processes and challenges.

- Ask about opportunities for professional development and career growth.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Jig and Fixture Builder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.