Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Liner Man position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

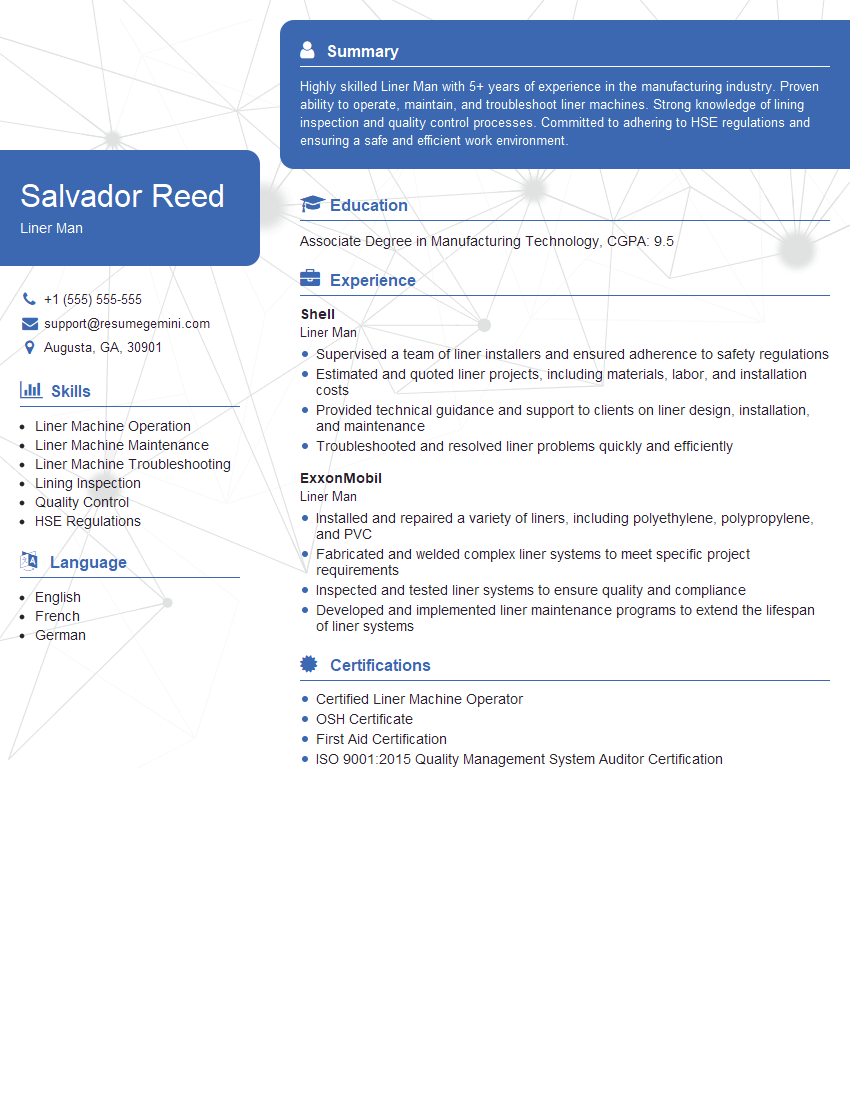

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Liner Man

1. What are the primary responsibilities of a Liner Man?

As a Liner Man, I would be responsible for the safe and efficient operation of the liner machine used in the production of corrugated cardboard or other similar materials. My key duties would include:

- Setting up and operating the liner machine according to established procedures and specifications.

- Monitoring the machine’s performance, identifying and resolving any issues or malfunctions promptly.

- Maintaining the liner machine, including regular cleaning, lubrication, and minor repairs.

- Inspecting and ensuring the quality of the liner produced, adhering to the company’s standards.

- Collaborating with other team members, including operators, supervisors, and maintenance personnel, to ensure smooth production.

2. Describe the different types of liner machines you have experience operating.

Single Facer Machines:

- Explain the operation and key features of single facer machines, such as corrugating rolls, glue applicators, and cut-off knives.

Double Facer Machines:

- Describe the process and components involved in double facer machines, including pre-heaters, glue systems, and pressure rollers.

Corrugator Machines:

- Explain the functionality and operation of corrugator machines, focusing on their ability to produce corrugated board from multiple layers of paper.

3. How do you troubleshoot and resolve common problems that occur on liner machines?

When troubleshooting and resolving issues on liner machines, I follow a systematic approach that involves the following steps:

- Identifying the problem accurately by observing machine behavior, listening for unusual sounds, and inspecting components.

- Consulting technical manuals and diagrams to understand the machine’s design and functionality.

- Performing diagnostics and tests to pinpoint the root cause of the problem, such as checking sensors, wiring, and mechanical components.

- Implementing appropriate solutions to resolve the issue, including adjusting machine settings, replacing faulty parts, or performing repairs.

- Testing the machine after repairs to ensure it is operating correctly and meets specifications.

4. What are the safety precautions you observe when operating liner machines?

Safety is paramount when operating liner machines, and I strictly adhere to the following precautions:

- Wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and earplugs.

- Ensuring the machine is properly guarded and all safety devices are in place and functional.

- Maintaining a clean and organized work area free from tripping hazards or obstructions.

- Following established lockout/tagout procedures when performing maintenance or repairs.

- Being aware of potential hazards such as moving parts, hot surfaces, and sharp edges, and taking appropriate precautions.

5. How do you maintain and calibrate liner machines to ensure optimal performance?

Regular maintenance and calibration are essential for keeping liner machines operating efficiently and accurately. My approach to maintenance includes:

- Performing routine inspections to identify potential issues and prevent breakdowns.

- Cleaning and lubricating machine components to reduce wear and tear.

- Replacing worn or damaged parts promptly to maintain machine integrity.

- Calibrating sensors and other measuring devices to ensure precise measurements and control.

- Following manufacturer’s recommendations for maintenance schedules and procedures.

6. What experience do you have with different types of paper and their properties?

I have experience working with various types of paper used in the production of corrugated board, including:

- Kraft paper: Known for its strength and durability, commonly used as the outer liner of corrugated board.

- Test liner: A recycled paperboard often used as the inner liner of corrugated board, providing cushioning and support.

- Medium paper: A fluted paperboard sandwiched between the liners, creating the corrugated structure and providing impact resistance.

- Coated paper: Paper with a special coating applied to enhance its properties, such as moisture resistance or printability.

- Specialty papers: Papers with unique characteristics, such as flame retardancy or antimicrobial properties, used for specific applications.

Understanding the properties of different paper types is crucial for selecting the appropriate materials and optimizing machine settings to achieve the desired product quality.

7. How do you ensure the quality of the liner produced on the machine?

Ensuring the quality of the liner produced is a top priority. I employ the following methods:

- Regularly monitoring machine performance and making adjustments as needed to maintain consistent product quality.

- Inspecting the liner visually and using measuring tools to verify dimensions, thickness, and other specifications.

- Conducting tests on the liner to assess its strength, moisture content, and other properties, ensuring it meets industry standards.

- Maintaining detailed records of production data to track quality trends and identify areas for improvement.

- Collaborating with the quality control department to resolve any quality issues and implement corrective actions.

8. Describe your experience with production planning and scheduling for liner machines.

Effective production planning and scheduling are essential for maximizing machine utilization and meeting customer demand:

- Reviewing production orders and determining the required machine setup and materials.

- Scheduling machine runs to optimize production flow and minimize downtime.

- Coordinating with other departments, such as purchasing and shipping, to ensure timely delivery of materials and products.

- Monitoring production progress and making adjustments as needed to meet deadlines.

- Analyzing production data to identify bottlenecks and areas for improvement in the scheduling process.

9. How do you handle unexpected machine breakdowns or production issues?

Unforeseen breakdowns or production issues require a prompt and effective response:

- Following established emergency procedures to ensure the safety of personnel and equipment.

- Quickly diagnosing the problem and implementing appropriate corrective actions.

- Communicating with supervisors, maintenance personnel, and other relevant parties to coordinate repairs and minimize downtime.

- Documenting the incident, including the cause, resolution, and any necessary follow-up actions.

- Learning from the incident to identify potential improvements in preventive maintenance or operating procedures.

10. What additional skills or experiences do you possess that would be valuable in this role?

- Proficient in Microsoft Office Suite and enterprise resource planning (ERP) systems.

- Understanding of lean manufacturing principles and their application in optimizing production processes.

- Experience in training and mentoring junior operators to enhance their skills and knowledge.

- Strong communication and interpersonal skills for effective collaboration and problem-solving.

- Ability to work independently and as part of a team in a fast-paced manufacturing environment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Liner Man.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Liner Man‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Liner Man is a skilled professional who is responsible for installing, maintaining, and repairing the liners used in various industrial and commercial applications. The key responsibilities of a Liner Man include:

1. Liner Installation

Installing new liners in tanks, vessels, and other equipment to prevent corrosion, abrasion, and other forms of damage.

- Measuring and cutting liners to the required specifications.

- Preparing surfaces for liner installation.

- Applying adhesives or bonding agents to secure liners in place.

- Inspecting and testing liners for proper installation.

2. Liner Maintenance

Inspecting liners regularly to identify any signs of wear, damage, or leaks.

- Making minor repairs to liners, such as patching holes or cracks.

- Cleaning and disinfecting liners to prevent the growth of bacteria and other microorganisms.

- Monitoring liner performance and providing maintenance recommendations.

3. Liner Repair

Repairing damaged liners by welding, patching, or replacing damaged sections.

- Assessing the extent of damage and determining the most appropriate repair method.

- Welding or bonding new liner material in place.

- Testing repaired liners to ensure they meet performance specifications.

4. Safety Compliance

Ensuring that all liner installation, maintenance, and repair activities are conducted in accordance with safety regulations and industry standards.

- Wearing appropriate safety gear, such as gloves, safety glasses, and respirators.

- Following established safety procedures for handling hazardous materials.

- Reporting any safety concerns or incidents to the appropriate authorities.

Interview Tips

To ace your interview for a Liner Man position, it is important to be well-prepared. Here are some tips to help you make a great impression:

1. Research the Company and Position

Before the interview, take the time to learn about the company and the specific Liner Man position. This will help you understand the company’s culture, values, and what they are looking for in a candidate.

- Visit the company’s website.

- Read industry news and articles.

- Talk to people in your network who work in the same industry.

2. Practice Your Answers

It is also important to practice your answers to common interview questions. This will help you feel more confident and prepared during the interview.

- Write down a list of potential interview questions.

- Practice answering each question out loud.

- Get feedback from a friend or family member.

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing a suit or business casual attire.

- Make sure your clothes are clean and pressed.

- Choose clothes that fit well and are comfortable to wear.

- Avoid wearing excessive jewelry or perfume.

4. Be Punctual

Punctuality is essential for a successful interview. Plan your route in advance and leave yourself plenty of time to get to the interview location.

- Aim to arrive at least 15 minutes early.

- If you are running late, call the interviewer to let them know.

- Do not be afraid to ask for directions if you are lost.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Liner Man interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!