Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Fixture Builder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

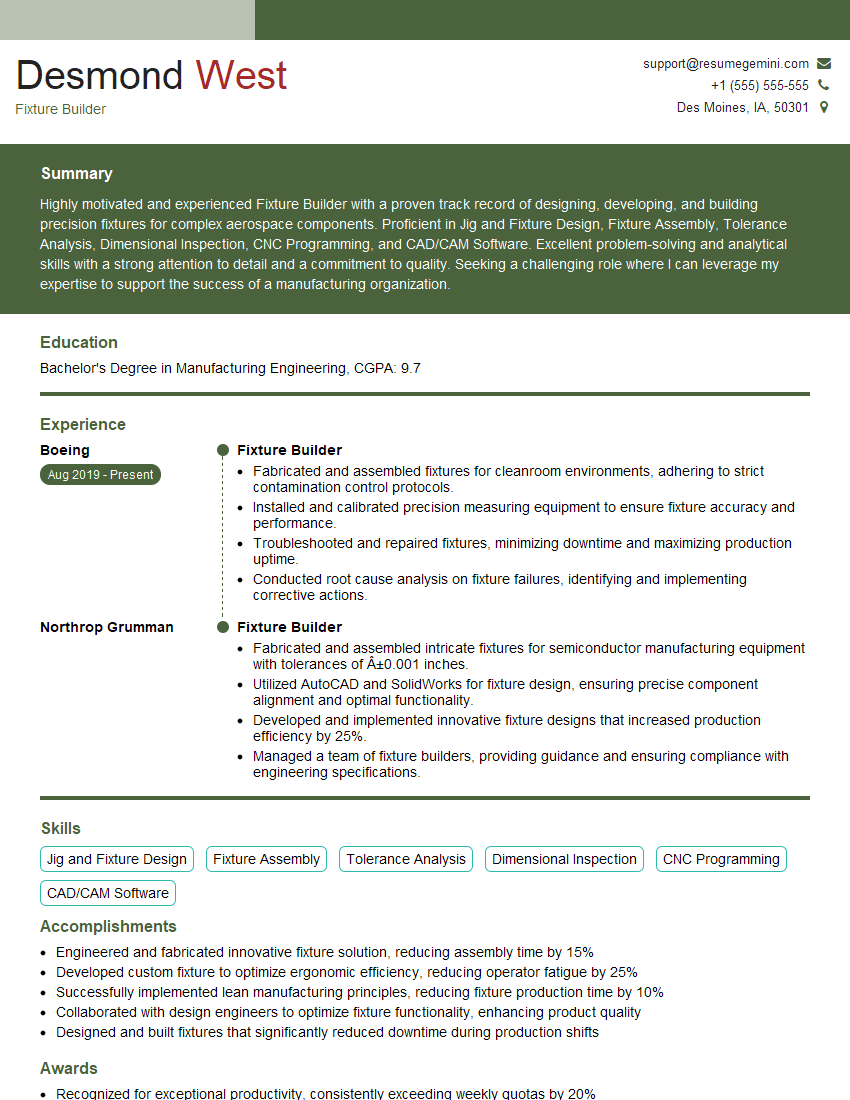

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fixture Builder

1. How would you define a Fixture and what are its key elements?

A Fixture is a device or structure used to hold, support, or locate a workpiece during manufacturing operations. Key elements include:

- Baseplates: Provide rigidity and stability.

- Locating Elements: Position and orient the workpiece precisely.

- Clamping Elements: Secure the workpiece in place.

- Auxiliary Elements: Enhance fixture functionality, such as gaging devices or coolant nozzles.

2. Describe the different types of Fixture Layouts and provide examples of their applications.

a) Dedicated Fixtures:

- Designed for a specific workpiece or operation.

- Provides high accuracy and repeatability.

b) Universal Fixtures:

- Adaptable to handle a range of workpieces.

- Less accurate than dedicated fixtures, but more versatile.

c) Modular Fixtures:

- Constructed from standardized components.

- Highly flexible and customizable to accommodate different workpieces.

3. Explain the importance of locating and clamping in fixture design.

Locating:

- Ensures precise workpiece positioning for accurate machining.

- Prevents workpiece movement during machining operations.

Clamping:

- Holds the workpiece securely in place.

- Prevents workpiece deformation or damage during cutting forces.

4. Discuss the factors to consider when selecting materials for fixture components.

Baseplates:

- Strength and rigidity to withstand machining forces.

- Durability to endure repeated use.

Locating Elements:

- Wear resistance to maintain accuracy over time.

- Corrosion resistance to prevent contamination of workpiece.

Clamping Elements:

- High clamping force to prevent workpiece movement.

- Ease of adjustment for quick and accurate workpiece setup.

5. Describe the steps involved in the design process of a Fixture.

1. Define Fixture Requirements:

- Identify workpiece dimensions, machining operations, and accuracy requirements.

2. Select Fixture Layout:

- Determine the most suitable type of fixture for the application.

3. Design Locating and Clamping Elements:

- Specify the type, size, and position of locating and clamping elements.

4. Select Fixture Materials:

- Consider the factors discussed in Question 4.

5. Create Fixture Drawings and Specifications:

- Document the detailed design for manufacturing and assembly.

6. Explain the techniques used to improve fixture rigidity.

a) Ribbing:

- Adding ribs to the fixture baseplate to increase stiffness.

b) Gusseting:

- Triangular reinforcements at corners or junctions to prevent bending.

c) T-slots and Dowel Pins:

- Provide precise alignment and secure connections between fixture components.

d) Use of High-Strength Materials:

- Selecting materials with high yield and tensile strength.

7. How do you ensure safety when designing and using Fixtures?

a) Safety Features:

- Incorporate guards to prevent operator contact with moving parts.

- Use non-slip surfaces to reduce the risk of accidents.

b) Operator Training:

- Provide proper training on fixture operation and maintenance.

c) Regular Maintenance:

- Inspect fixtures regularly for wear or damage.

- Perform maintenance and repair as needed to ensure proper functionality and safety.

8. Discuss the role of computer-aided design (CAD) in Fixture Design.

a) 3D Modeling:

- Create accurate 3D models of the fixture and workpiece.

b) Finite Element Analysis (FEA):

- Analyze fixture rigidity and stress distribution.

- Optimize fixture design to improve performance.

c) Automation:

- Automate fixture design processes, reducing time and effort.

9. What are the common errors to avoid in Fixture Design?

a) Inadequate Locating:

- Incorrect or insufficient locating elements.

b) Excessive Clamping:

- Applying too much clamping force, damaging the workpiece.

c) Poor Material Selection:

- Using materials that are not suited for the application.

d) Lack of Safety Features:

- No provisions for operator safety or proper maintenance.

10. Stay updated with the latest advances in Fixture Building Technology.

a) Additive Manufacturing (3D Printing):

- Producing complex and customized fixtures.

b) Robotics and Automation:

- Automating fixture setup and alignment.

c) Advanced Materials:

- Developing new materials with enhanced properties for fixture components.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fixture Builder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fixture Builder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fixture Builders are highly skilled professionals responsible for designing, building, and maintaining jigs and fixtures used in manufacturing processes. They possess a strong understanding of engineering principles and have a keen eye for detail.

1. Design and Development

Fixture Builders create detailed plans and blueprints for fixtures, ensuring they meet specific requirements.

- Collaborate with engineers and designers to analyze product specifications and determine fixture requirements.

- Develop fixture concepts and design drawings using CAD software (e.g., SolidWorks, AutoCAD).

2. Fabrication and Assembly

They construct fixtures using various materials, such as metal, plastic, and wood, ensuring accuracy and precision.

- Select and prepare materials according to design specifications.

- Use precision tools and equipment, such as CNC machines, welding equipment, and assembly jigs, to fabricate and assemble fixtures.

3. Installation and Maintenance

Fixture Builders install and maintain fixtures within production lines, ensuring optimal performance.

- Install fixtures and ensure proper alignment and operation.

- Conduct regular inspections and perform maintenance tasks, such as lubrication and adjustment, to prevent breakdowns.

4. Quality Control

They monitor fixture performance and implement quality control measures to ensure consistent and high-quality output.

- Inspect fixtures to verify accuracy, precision, and functionality.

- Identify and resolve any issues or defects, ensuring fixtures meet performance standards.

Interview Tips

To ace the interview for a Fixture Builder position, candidates should prepare thoroughly and demonstrate their skills and experience effectively.

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and industry trends. This shows interest and helps you align your answers to the company’s needs.

2. Highlight Your Skills and Experience

Emphasize your technical skills in fixture design, fabrication, and quality control. Use specific examples to demonstrate your ability to handle complex projects.

3. Showcase Your Problem-Solving Abilities

Provide instances of how you identified and resolved fixture-related problems. Explain your analytical approach and how you applied your knowledge to develop solutions.

4. Demonstrate Your Attention to Detail

Highlight your meticulous approach and ability to work with precision. Mention any certifications or training programs that demonstrate your attention to detail.

5. Prepare Questions for the Interviewer

Asking thoughtful questions shows engagement and interest. Prepare questions about the company’s fixture design philosophy, project management processes, or industry best practices.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fixture Builder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!