Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Journeyman Patternmaker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

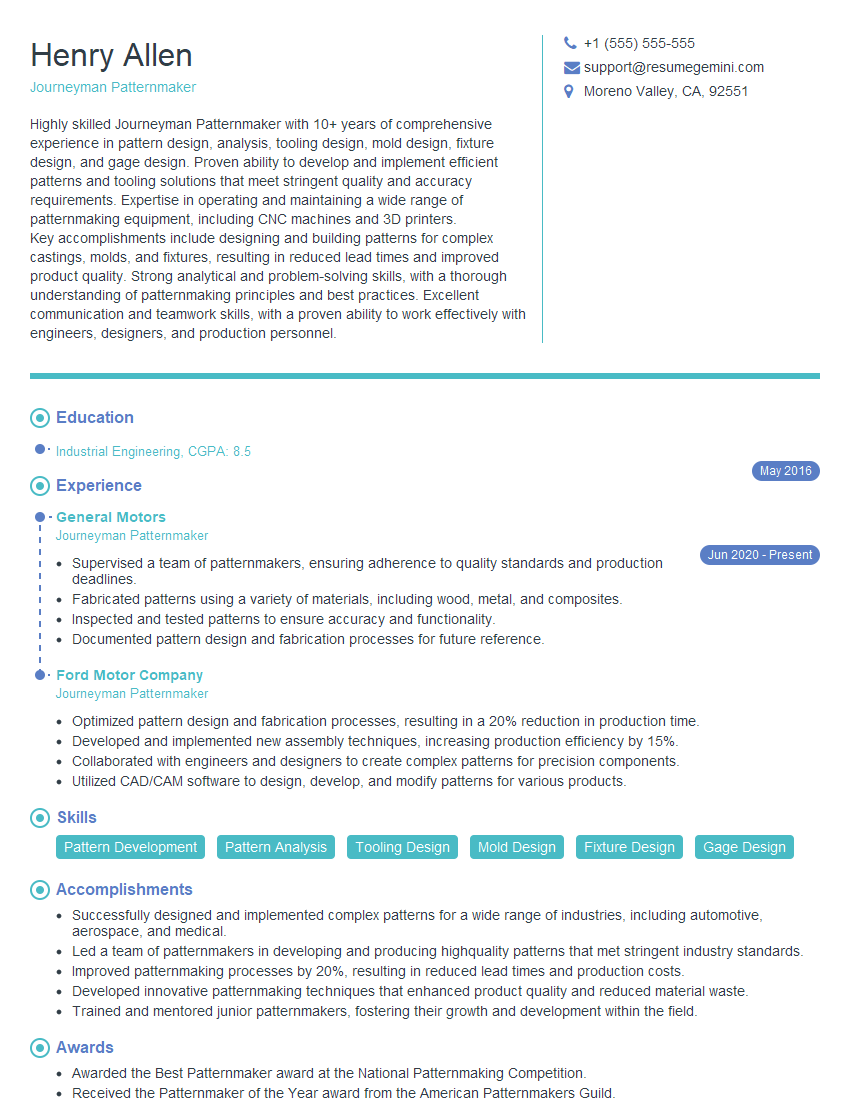

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Journeyman Patternmaker

1. Explain the process of creating a pattern for a complex casting?

The process of creating a pattern for a complex casting can be broken down into several key steps:

- Develop a detailed design of the casting, taking into account the geometry, tolerances, and material properties.

- Create a scaled model of the casting, typically using CAD software or 3D modeling tools.

- Fabricate the pattern, typically using wood, metal, or plastic, that will represent the shape of the casting.

- Inspect the pattern for accuracy and make any necessary adjustments to ensure that the casting will meet the design specifications.

- Produce the casting using the pattern and the appropriate molding and casting processes.

2. What are the different types of pattern materials and when would you use each type?

Wood

- Inexpensive and easy to work with

- Suitable for small to medium-sized castings

- Not suitable for high-temperature or high-pressure casting processes

Metal

- Durable and can withstand high temperatures

- Suitable for large and complex castings

- Expensive and can be difficult to work with

Plastic

- Lightweight and easy to modify

- Suitable for small to medium-sized castings

- Not suitable for high-temperature casting processes

3. How do you calculate the shrinkage allowance for a pattern?

The shrinkage allowance for a pattern is calculated by multiplying the linear dimension of the pattern by the shrinkage factor of the material being cast. The shrinkage factor is a constant value that is determined by the material being cast and the casting process being used.

4. What are the tolerances that must be considered when creating a pattern?

- Dimensional tolerances: These tolerances specify the allowable variation in the dimensions of the pattern.

- Form tolerances: These tolerances specify the allowable variation in the form of the pattern, such as its flatness, straightness, and roundness.

- Surface finish tolerances: These tolerances specify the allowable roughness of the surface of the pattern.

5. What are the different methods of gating and risering a pattern?

Gating

- Sprues: These are the channels through which the molten metal enters the mold

- Gates: These are the channels that connect the sprues to the casting cavity

Risering

- Risers: These are reservoirs of molten metal that are added to the mold to compensate for shrinkage during solidification

- Feeder heads: These are large risers that are attached directly to the casting cavity

6. What are the different types of casting defects and how do you prevent them?

Casting Defects

- Shrinkage cavities: These are caused by the solidification of the metal, which results in a decrease in volume

- Gas porosity: These are caused by the entrapment of gases in the molten metal

- Cold shuts: These are caused by the premature solidification of the metal, which results in a lack of fusion between the different parts of the casting

Prevention

- Using proper gating and risering techniques

- Controlling the temperature of the molten metal

- Using the correct molding materials

7. What are the safety precautions that must be taken when working with patterns?

- Wear appropriate protective clothing, including gloves, safety glasses, and a dust mask.

- Use sharp tools carefully and avoid cutting yourself.

- Be aware of the location of electrical wires and other hazards.

- Keep the work area clean and free of debris.

- Follow all safety procedures and guidelines.

8. What are the latest trends and technologies in patternmaking?

- 3D printing: This technology is used to create patterns directly from CAD models.

- Computer-aided patternmaking: This software helps patternmakers design and create patterns more efficiently.

- Virtual reality: This technology is used to create realistic simulations of the casting process.

9. What are your strengths and weaknesses as a patternmaker?

Strengths

- Skilled in the use of various patternmaking tools and techniques

- Knowledge of casting materials and processes

- Attention to detail and accuracy

- Ability to work independently and as part of a team

Weaknesses

- Limited experience with 3D printing

- Not familiar with all the latest computer-aided patternmaking software

10. Why are you interested in this position?

I am interested in this position because it would allow me to use my patternmaking skills and knowledge to contribute to the success of your company. I am confident that I have the skills and experience necessary to be a valuable asset to your team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Journeyman Patternmaker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Journeyman Patternmaker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Journeyman Patternmakers play a crucial role in the manufacturing industry, specializing in the creation and repair of patterns used in producing molds for casting. Their responsibilities encompass a wide range of tasks, ensuring the accuracy and precision of patterns essential for the production of quality castings.

1. Pattern Creation and Modification

Journeyman Patternmakers are responsible for creating new patterns based on design specifications and modifying existing patterns to meet specific requirements.

- Interpreting blueprints, drawings, and other technical documentation to understand design requirements.

- Selecting appropriate materials and construction methods for pattern fabrication.

- Using hand tools, power tools, and specialized equipment to shape, join, and finish patterns.

- Inspecting patterns to ensure accuracy and compliance with design specifications.

2. Pattern Repair and Maintenance

Journeyman Patternmakers maintain and repair existing patterns to ensure their continued functionality in the production process.

- Identifying and diagnosing pattern defects or damage.

- Repairing patterns using appropriate techniques and ensuring restored accuracy.

- Performing regular maintenance and cleaning to prevent wear and tear.

3. Quality Control

Journeyman Patternmakers play a pivotal role in maintaining the quality of patterns and castings.

- Inspecting patterns regularly to ensure precision and dimensional accuracy.

- Conducting tests and measurements to verify pattern quality.

- Collaborating with other professionals to identify and resolve quality issues.

4. Safety and Compliance

Journeyman Patternmakers prioritize safety and compliance in their work environment.

- Adhering to safety protocols and wearing appropriate personal protective equipment.

- Maintaining a clean and organized work area to prevent accidents.

- Following environmental regulations and industry standards.

Interview Tips

Preparing for a Journeyman Patternmaker interview requires a combination of technical knowledge and a strong understanding of the industry. Here are some tips to help candidates ace the interview:

1. Research the Company and Role

Thoroughly research the company’s history, industry standing, and specific job requirements. This demonstrates your interest in the position and shows that you have taken the time to learn about their organization.

- Visit the company website and review their mission, values, and current projects.

- Read industry news and articles to stay up-to-date on the latest advancements and trends.

- Identify specific aspects of the role that align with your skills and experience.

2. Showcase Your Technical Skills and Experience

Highlight your proficiency in patternmaking techniques, materials, and equipment. Quantify your accomplishments and provide specific examples of your work.

- Describe your experience in creating complex patterns from various materials.

- Explain your knowledge of pattern repair methods and quality control techniques.

- Share examples of your ability to meet tight deadlines and work effectively in a team environment.

3. Emphasize Your Commitment to Safety and Quality

Emphasize your commitment to safety by highlighting your understanding of industry regulations and your adherence to safety protocols. Additionally, demonstrate your dedication to quality by discussing your attention to detail and your ability to produce precise patterns that meet customer specifications.

- Describe your experience in implementing safety measures in the workplace.

- Explain your understanding of the importance of quality control in patternmaking.

- Provide examples of your ability to identify and resolve quality issues.

4. Prepare Questions for the Interviewer

Preparing questions to ask the interviewer demonstrates your interest in the position and the company. It also gives you an opportunity to clarify any information or gain additional insights.

- Inquire about the company’s future projects and growth plans.

- Ask about the specific challenges and opportunities associated with the role.

- Request information about the company’s training and development programs.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Journeyman Patternmaker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Journeyman Patternmaker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.