Are you gearing up for an interview for a Metal Patternmaker Apprentice position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Metal Patternmaker Apprentice and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

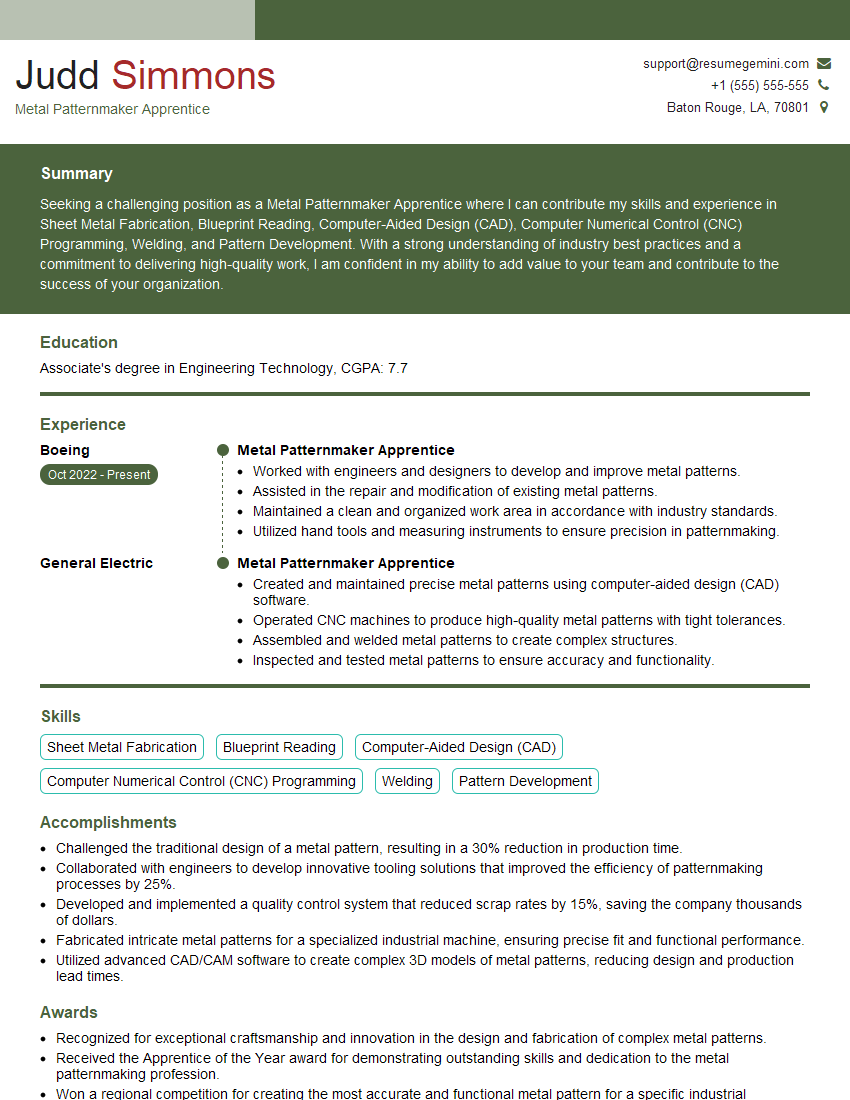

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Patternmaker Apprentice

1. What are the different types of metal patterns and their uses?

- Single-piece patterns: These are used for simple castings that do not require any parting lines.

- Two-piece patterns: These are used for more complex castings that require a parting line to separate the mold into two halves.

- Multi-piece patterns: These are used for very complex castings that require multiple parting lines to separate the mold into multiple pieces.

- Loose patterns: These are not attached to a mounting plate and can be used to make multiple castings from the same pattern.

- Mounted patterns: These are attached to a mounting plate and are used for high-volume production casting.

2. What are the different materials used to make metal patterns and their advantages and disadvantages?

- Wood: Wood is a traditional material for making metal patterns. It is relatively inexpensive and easy to work with, but it is not as durable as other materials.

- Metal: Metal patterns are more durable than wood patterns, but they are also more expensive. They can be made from a variety of metals, including aluminum, steel, and cast iron.

- Plastic: Plastic patterns are lightweight and durable, but they are not as strong as metal patterns. They can be made from a variety of plastics, including ABS, PVC, and nylon.

3. What are the different processes involved in making a metal pattern?

- Design: The first step is to design the pattern. This can be done using a variety of methods, including hand sketching, CAD software, or 3D modeling.

- Fabrication: Once the design is complete, the pattern is fabricated. This can be done using a variety of methods, including machining, casting, or welding.

- Finishing: Once the pattern is fabricated, it is finished. This may involve sanding, painting, or plating.

4. What are the different types of casting defects and how can they be prevented?

- Shrinkage: Shrinkage occurs when the metal solidifies and cools, causing it to contract. This can lead to voids or cracks in the casting.

- Porosity: Porosity occurs when gas bubbles are trapped in the metal during solidification. This can lead to weak spots in the casting.

- Cold shuts: Cold shuts occur when two streams of molten metal meet and do not fuse together. This can lead to weak spots in the casting.

5. What are the different types of pattern equipment and how are they used?

- Pattern plates: Pattern plates are used to mount patterns to a molding machine.

- Gates: Gates are used to introduce molten metal into the mold.

- Risers: Risers are used to provide extra molten metal to the casting to prevent shrinkage defects.

- Chills: Chills are used to cool certain areas of the casting to promote directional solidification.

6. What are the different types of pattern allowances and how are they calculated?

- Shrinkage allowance: Shrinkage allowance is added to the pattern to compensate for the shrinkage that occurs when the metal solidifies and cools.

- Draft allowance: Draft allowance is added to the pattern to allow the casting to be removed from the mold without damage.

- Machining allowance: Machining allowance is added to the pattern to allow for the casting to be machined to final dimensions.

7. What are the different types of pattern finishes and how are they applied?

- Sanding: Sanding is used to smooth the surface of the pattern.

- Painting: Painting is used to protect the pattern from corrosion and wear.

- Plating: Plating is used to apply a thin layer of metal to the pattern to improve its durability.

8. What are the different types of pattern storage and handling methods?

- Pattern racks: Pattern racks are used to store patterns vertically.

- Pattern cabinets: Pattern cabinets are used to store patterns horizontally.

- Pattern vaults: Pattern vaults are used to store patterns in a climate-controlled environment.

9. What are the different types of pattern inspection methods?

- Visual inspection: Visual inspection is used to identify any defects in the pattern.

- Dimensional inspection: Dimensional inspection is used to verify the accuracy of the pattern’s dimensions.

- Functional inspection: Functional inspection is used to test the pattern’s ability to produce a satisfactory casting.

10. What are the different types of pattern repair methods?

- Welding: Welding is used to repair cracks or other damage to the pattern.

- Brazing: Brazing is used to repair small cracks or other damage to the pattern.

- Soldering: Soldering is used to repair small cracks or other damage to the pattern.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Patternmaker Apprentice.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Patternmaker Apprentice‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Metal Patternmaker Apprentice, you will assist senior patternmakers in the creation and maintenance of patterns used in metal casting. Your daily tasks may include:

1. Patternmaking Basics

Gain hands-on experience in various patternmaking techniques, such as:

- Woodworking and metalworking

- Layout and scribing

- Hand and power tool usage

2. Pattern Design and Development

Assist in designing and developing patterns based on engineering drawings and specifications.

3. Pattern Fabrication

Construct patterns using a variety of materials, including wood, metal, and plastics.

4. Pattern Inspection and Repair

Inspect patterns for accuracy and quality, and make repairs or modifications as needed.

Interview Tips

To prepare for your interview, consider the following tips:

1. Research the Company and Role

Research the company’s history, products/services, and industry standing. Thoroughly review the job description to understand the specific requirements and responsibilities of the Metal Patternmaker Apprentice position.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience in areas such as woodworking, metalworking, or patternmaking. If you have any formal training or apprenticeships, be sure to mention them.

3. Prepare Examples of Your Work

If possible, bring examples of your work, such as drawings, patterns, or projects you have completed. This will demonstrate your skills and abilities to the interviewer.

4. Practice Answering Common Interview Questions

Prepare answers to common interview questions, such as “Why are you interested in this position?” or “What are your strengths and weaknesses?”. Practice your answers out loud to improve your delivery and confidence.

5. Dress Professionally and Arrive on Time

Make a good first impression by dressing professionally and arriving on time for your interview. This shows respect for the interviewer and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Metal Patternmaker Apprentice interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!