Feeling lost in a sea of interview questions? Landed that dream interview for Mold / Die Repairer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Mold / Die Repairer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

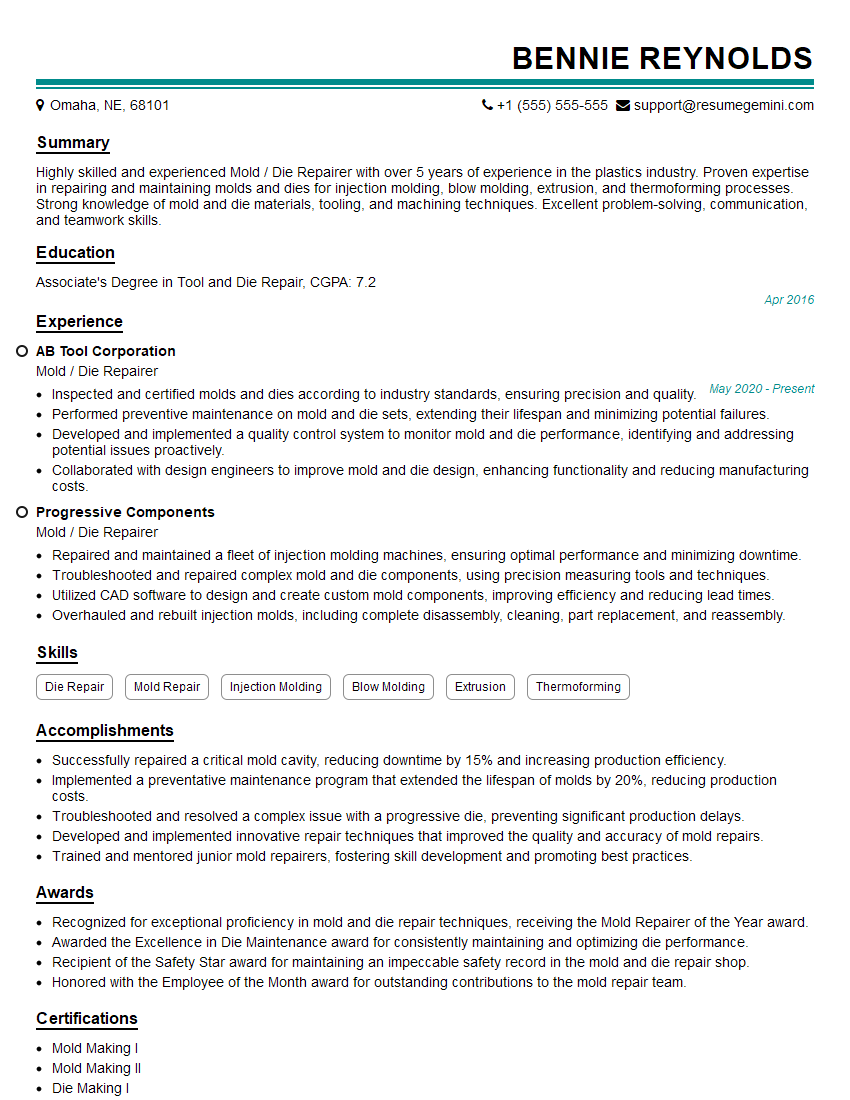

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mold / Die Repairer

1. What are the different types of mold repair techniques?

- Welding

- Brazing

- Machining

- Coating

- Patching

2. What are the common materials used in mold and die repair?

- Steel

- Aluminum

- Plastic

- Ceramics

- Composites

3. What are the steps involved in mold repair?

The steps involved in mold repair may vary depending on the type of repair, but generally include:

- Inspection of the mold

- Cleaning the mold

- Repairing the mold

- Testing the mold

4. What are the different types of welding used in mold repair?

- Arc welding

- MIG welding

- TIG welding

- Laser welding

5. What are the different types of coatings used in mold repair?

- Metallic coatings

- Ceramic coatings

- Polymer coatings

- Composite coatings

6. What are the different types of machining used in mold repair?

- Milling

- Turning

- Drilling

- Grinding

7. What are the different types of testing used to ensure the quality of mold repairs?

- Visual inspection

- Dimensional inspection

- Functional testing

8. What are the safety precautions that should be taken when performing mold repair?

- Wear appropriate safety gear, such as gloves, safety glasses, and a respirator.

- Ensure that the work area is well-ventilated.

- Use sharp tools and equipment only.

- Follow all safety procedures and protocols.

9. What are the common causes of mold failure?

- Wear and tear

- Corrosion

- Impact damage

- Improper maintenance

10. What are the benefits of preventative mold maintenance?

- Reduced downtime

- Improved product quality

- Extended mold life

- Reduced repair costs

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mold / Die Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mold / Die Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mold/Die Repairers possess the skills and knowledge required to maintain the performance and reliability of molds and dies used in manufacturing processes.

1. Repair and Recondition Molds/Dies

Inspect and evaluate molds/dies to identify defects, wear, and damage.

- Utilize diagnostic tools and techniques to pinpoint the root cause of issues.

- Repair or replace damaged components, such as pins, bushings, and guide rails.

- Recondition worn surfaces using specialized equipment and techniques.

2. Preventive Maintenance

Perform scheduled inspections, cleanings, and adjustments to prevent breakdowns and extend the life of molds/dies.

- Monitor performance parameters, such as cycle times and part quality.

- Lubricate moving parts, adjust settings, and replace worn components.

- Document maintenance activities and make recommendations for improvements.

3. Installation and Alignment

Install and align new or repaired molds/dies into presses or other production equipment.

- Ensure proper fit and alignment to minimize downtime and optimize production.

- Use precision measuring tools and equipment to achieve exact specifications.

4. Troubleshooting and Problem-Solving

Troubleshoot and resolve issues that affect the performance of molds/dies.

- Analyze symptoms and diagnose potential causes.

- Implement solutions to correct defects, improve efficiency, and prevent recurrence.

Interview Tips

To ace the interview for a Mold/Die Repairer position, consider the following tips:

1. Research the Company and Position

Before the interview, thoroughly research the company and the specific position you are applying for.

- Visit the company’s website to learn about their products, services, and industry.

- Review the job description to identify the key responsibilities and qualifications.

2. Highlight Your Technical Skills

In the interview, emphasize your technical skills and experience in mold/die repair and maintenance.

- Discuss your proficiency in using diagnostic tools, precision measuring equipment, and repair techniques.

- Provide examples of successful repairs or troubleshooting projects you have completed.

3. Demonstrate Your Problem-Solving Abilities

Mold/Die Repairers need to be able to identify and resolve problems quickly and efficiently.

- Share examples of situations where you diagnosed and solved complex issues.

- Explain your approach to problem-solving, focusing on analytical thinking and attention to detail.

4. Show Your Passion for the Field

Convey your genuine interest in mold/die repair and maintenance.

- Explain why you enjoy working with molds and dies.

- Share your knowledge of industry trends and best practices.

Next Step:

Now that you’re armed with the knowledge of Mold / Die Repairer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Mold / Die Repairer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini