Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Plastics Patternmaker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

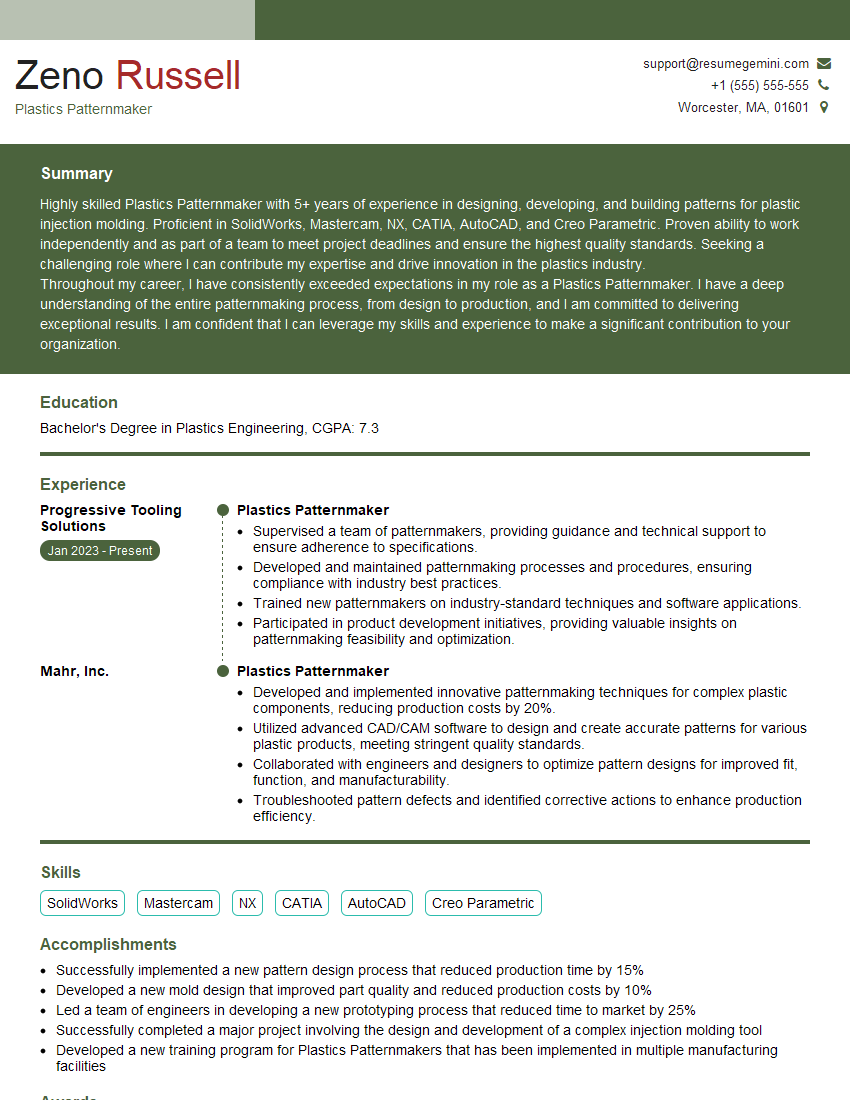

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plastics Patternmaker

1. What are the different types of plastics used in pattern making, and what are their advantages and disadvantages?

There are three main types of plastics used in pattern making:

- Epoxy resin: Epoxy resin is a strong and durable material that is resistant to heat and chemicals. It is also relatively easy to work with.

- Polyurethane resin: Polyurethane resin is a lightweight and flexible material that is easy to cast. It is also relatively inexpensive.

- ABS plastic: ABS plastic is a strong and durable material that is resistant to impact and chemicals. It is also relatively easy to machine.

2. What are the different methods of pattern making, and what are their advantages and disadvantages?

There are two main methods of pattern making:

- Hand lay-up: Hand lay-up is a process in which the pattern is made by hand using a mold. This method is relatively simple and inexpensive, but it can be time-consuming.

- CNC machining: CNC machining is a process in which the pattern is made using a computer-controlled machine. This method is more precise and efficient than hand lay-up, but it can be more expensive.

3. What are the different types of finishes that can be applied to plastic patterns?

There are several different types of finishes that can be applied to plastic patterns, including:

- Paint: Paint can be used to give the pattern a smooth, glossy finish. It is also relatively easy to apply.

- Clear coat: Clear coat can be used to protect the pattern from wear and tear. It can also give the pattern a glossy finish.

- Wax: Wax can be used to give the pattern a natural finish. It is also relatively easy to apply.

4. What are the different types of tools and equipment that are used in pattern making?

There are a variety of different tools and equipment that are used in pattern making, including:

- Molds: Molds are used to create the shape of the pattern. They can be made from a variety of materials, including wood, metal, and plastic.

- Laminates: Laminates are used to build up the thickness of the pattern. They can be made from a variety of materials, including fiberglass, carbon fiber, and Kevlar.

- Resins: Resins are used to bind the laminates together. They can be made from a variety of materials, including epoxy, polyurethane, and polyester.

- Tools: A variety of tools are used to shape and finish the pattern, including saws, sanders, and routers.

5. What are the safety precautions that should be taken when working with plastics?

There are a number of safety precautions that should be taken when working with plastics, including:

- Wear a respirator: When working with plastics, it is important to wear a respirator to protect your lungs from harmful fumes.

- Wear gloves: When working with plastics, it is important to wear gloves to protect your skin from contact with harmful chemicals.

- Wear eye protection: When working with plastics, it is important to wear eye protection to protect your eyes from flying debris.

- Ventilate the area: When working with plastics, it is important to ventilate the area to prevent the build-up of harmful fumes.

6. What are the different types of defects that can occur in plastic patterns?

There are a number of different types of defects that can occur in plastic patterns, including:

- Voids: Voids are air pockets that can occur in the pattern. They can weaken the pattern and make it more susceptible to damage.

- Cracks: Cracks can occur in the pattern due to stress or impact. They can weaken the pattern and make it more likely to fail.

- Delamination: Delamination is the separation of the laminates in the pattern. It can weaken the pattern and make it more likely to fail.

- Warping: Warping is the distortion of the pattern due to heat or moisture. It can make the pattern difficult to use.

7. What are the different types of testing that can be performed on plastic patterns?

There are a number of different types of testing that can be performed on plastic patterns, including:

- Visual inspection: Visual inspection is a simple but effective way to identify defects in the pattern.

- Dimensional inspection: Dimensional inspection is used to verify the dimensions of the pattern. It can be performed using a variety of tools, including calipers and micrometers.

- Strength testing: Strength testing is used to determine the strength of the pattern. It can be performed using a variety of methods, including tensile testing and compressive testing.

- Durability testing: Durability testing is used to determine the durability of the pattern. It can be performed using a variety of methods, including impact testing and fatigue testing.

8. What are the different quality standards that are used in pattern making?

There are a number of different quality standards that are used in pattern making, including:

- ISO 9001: ISO 9001 is a quality management system standard that can be used by organizations to improve their quality management practices.

- ASME B46.1: ASME B46.1 is a standard that defines the dimensions and tolerances for plastic patterns.

- MIL-STD-45662: MIL-STD-45662 is a standard that defines the requirements for the inspection and testing of plastic patterns.

9. What are the different trends in pattern making?

There are a number of different trends in pattern making, including:

- The use of 3D printing: 3D printing is a new technology that can be used to create complex patterns quickly and easily.

- The use of composite materials: Composite materials are made from a combination of different materials, such as fiberglass and carbon fiber. They are strong and lightweight, and they can be used to create complex patterns.

- The use of software: Software can be used to design and create patterns. It can also be used to simulate the performance of patterns.

10. What are the different career paths for plastics patternmakers?

There are a number of different career paths for plastics patternmakers, including:

- Patternmaker: Patternmakers create patterns for a variety of products, including toys, furniture, and automotive parts.

- Model maker: Model makers create models for a variety of purposes, including design, engineering, and marketing.

- Tool and die maker: Tool and die makers create tools and dies for a variety of purposes, including stamping, molding, and forging.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plastics Patternmaker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plastics Patternmaker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Plastics Patternmaker is a skilled professional responsible for creating patterns, models, and molds used in the production of plastic parts. They collaborate with engineers, designers, and production teams to ensure the accuracy and quality of the final products.

1. Pattern and Model Making

Develop and construct patterns and models for plastic parts using various materials such as wood, metal, and composites.

- Analyze design specifications to determine pattern requirements.

- Select and utilize appropriate materials and techniques for pattern construction.

2. Mold Fabrication

Create molds based on the patterns and models using various molding techniques such as injection molding, blow molding, and thermoforming.

- Design and fabricate mold components, including core boxes, cavity inserts, and gates.

- Ensure the accuracy and quality of molds to produce parts that meet specifications.

3. Quality Control and Inspection

Inspect patterns, models, and molds to ensure their accuracy, precision, and conformance to design specifications.

- Use measuring instruments and gauges to verify dimensions and tolerances.

- Identify and correct any defects or deviations from specifications.

4. Collaboration and Communication

Collaborate with engineers, designers, and production teams to ensure the successful completion of projects.

- Communicate technical information clearly and effectively.

- Provide feedback and recommendations to improve product design and manufacturing processes.

Interview Tips

Preparing for an interview for a Plastics Patternmaker position requires a combination of technical expertise and effective communication skills. Here are some tips to help candidates ace the interview:

1. Research the Company and Role

Thoroughly research the company’s products, services, and manufacturing processes. This will demonstrate your interest and understanding of the organization.

- Review the job description carefully and identify the key responsibilities and skills required.

- Visit the company’s website and social media pages for insights into their culture and values.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in pattern making, mold fabrication, and quality control. Quantify your achievements whenever possible.

- Discuss specific projects where you successfully created patterns, molds, and parts that met or exceeded expectations.

- Provide examples of your experience in using industry-standard software and equipment.

3. Showcase Your Problem-Solving Abilities

Interviewers will be interested in your ability to solve problems and adapt to challenges. Prepare examples of situations where you used your skills to troubleshoot and resolve issues.

- Describe a time when you identified a defect in a pattern or mold and developed a solution to correct it.

- Explain how you collaborated with a team to overcome a production obstacle and achieve project goals.

4. Emphasize Quality Control and Precision

Plastics Patternmakers must have a keen eye for detail and a commitment to producing accurate, high-quality work.

- Discuss your understanding of quality control processes and your experience in using measuring instruments and gauges.

- Highlight your ability to maintain a clean and organized work environment.

5. Practice Your Communication Skills

Effective communication is essential for collaborating with engineers, designers, and production teams. Practice describing your technical skills and experience clearly and concisely.

- Prepare for questions about your ability to work independently and as part of a team.

- Be prepared to discuss your contributions to project successes and areas for improvement.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Plastics Patternmaker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.