Are you gearing up for a career in Foundry Worker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Foundry Worker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

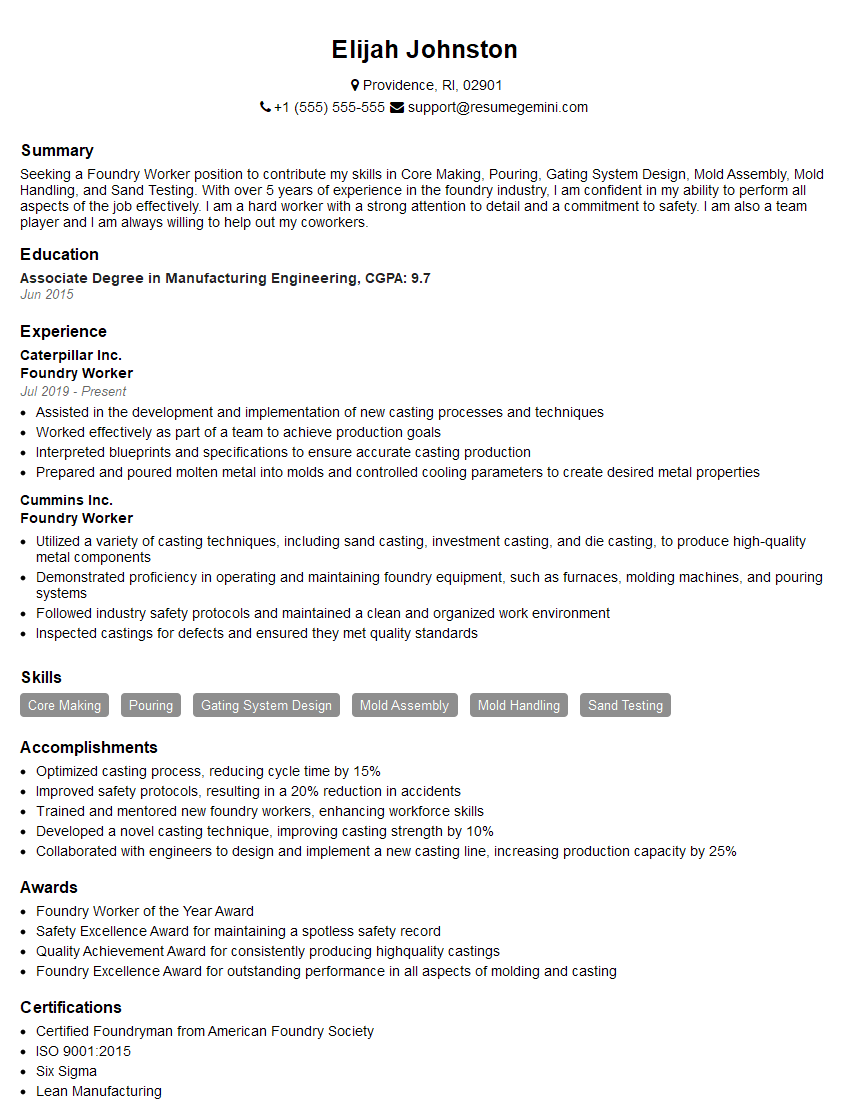

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Foundry Worker

1. Explain the process of sand casting and its advantages and disadvantages?

Sand casting is a metal casting process that uses sand as the mold material. The process begins with the creation of a pattern, which is a replica of the final product. The pattern is then used to create a mold in the sand. The molten metal is then poured into the mold, where it solidifies and takes the shape of the pattern.

The advantages of sand casting include:

- Relatively low cost

- Can be used to produce complex shapes

- Suitable for a wide range of materials

The disadvantages of sand casting include:

- Relatively low dimensional accuracy

- Can be labor-intensive

- May require post-processing to remove defects

2. How do you ensure the quality of castings?

Quality Control Measures

- Inspecting raw materials for defects

- Testing molds and cores for accuracy

- Monitoring the melting and pouring process

Inspection Methods

- Visual inspection

- Dimensional inspection

- Non-destructive testing (NDT)

3. What types of defects can occur in castings and how do you prevent them?

- Shrinkage porosity: Caused by shrinkage of the metal as it cools, can be prevented by using proper gating and risering techniques.

- Gas porosity: Caused by the entrapment of gases in the metal, can be prevented by degassing the metal or using vacuum casting techniques.

- Cold shuts: Caused by premature solidification of the metal at the mold-metal interface, can be prevented by ensuring proper fluidity of the metal.

- Hot tears: Caused by the formation of cracks in the metal due to thermal stresses, can be prevented by using proper mold design and cooling techniques.

4. What are the different types of furnaces used in foundries and their applications?

- Cupola furnace: Used for melting iron and ferrous alloys.

- Electric arc furnace: Used for melting steel and other high-melting-point metals.

- Induction furnace: Used for melting non-ferrous metals such as aluminum, copper, and brass.

- Crucible furnace: Used for melting small quantities of metal for casting or heat treatment.

5. How do you calculate the amount of sand needed for a mold?

I would use the following formula to calculate the amount of sand needed for a mold:

Amount of sand = Volume of mold + 10% for waste

Where:

- Volume of mold = Length x Width x Height

- 10% for waste = To account for spillage, loss during handling, and other factors

6. What are the safety precautions that should be taken when working in a foundry?

- Wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and a hard hat.

- Be aware of the location of fire extinguishers and other safety equipment.

- Follow established safety procedures, such as lockout/tagout.

- Keep the work area clean and free of tripping hazards.

- Never operate machinery without proper training.

7. What are your strengths and weaknesses as a Foundry Worker?

Strengths:

- Skilled in sand casting, investment casting, and other foundry processes.

- Experienced in operating a variety of foundry equipment, including furnaces, molding machines, and sand mixers.

- Excellent attention to detail and quality control.

Weaknesses:

- Limited experience with automated foundry systems.

- Need to improve efficiency in some areas.

8. What are your salary expectations?

My salary expectations are in line with the industry average for Foundry Workers with my experience and qualifications. I am also willing to negotiate based on the specific responsibilities of the position and the benefits package offered.

9. Why are you interested in this position?

I am interested in this position because it offers an opportunity to utilize my skills and experience in a challenging and rewarding environment. I am also impressed by the company’s commitment to quality and innovation, and I believe that I can make a significant contribution to the team.

10. Do you have any questions for me?

Yes, I have a few questions:

- Can you tell me more about the specific responsibilities of the position?

- What is the company’s safety record?

- What opportunities are there for professional development?

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Foundry Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Foundry Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Foundry Workers are responsible for operating and maintaining equipment used in the production of metal castings. They ensure that the equipment is functioning properly and that the castings meet quality standards.

1. Operating Equipment

Foundry Workers operate a variety of equipment, including furnaces, molding machines, and casting machines. They must be able to operate the equipment safely and efficiently.

- Operate furnaces to melt metal

- Operate molding machines to create molds for the castings

- Operate casting machines to pour molten metal into the molds

2. Maintaining Equipment

Foundry Workers are also responsible for maintaining the equipment that they use. They must be able to identify and troubleshoot problems, and make repairs as needed.

- Inspect equipment for wear and tear

- Lubricate and adjust equipment

- Repair or replace damaged parts

3. Ensuring Quality

Foundry Workers must ensure that the castings that they produce meet quality standards. They must be able to inspect castings for defects, and make adjustments to the equipment or process as needed to correct any problems.

- Inspect castings for defects

- Make adjustments to the equipment or process to correct any problems

- Maintain records of casting quality

4. Safety

Foundry Workers must follow all safety procedures to protect themselves and others from injury. They must be aware of the hazards of the job, and take steps to avoid accidents.

- Wear appropriate safety gear

- Follow all safety procedures

- Report any unsafe conditions

Interview Tips

Preparing for a Foundry Worker interview can be daunting, but by following these tips, you can increase your chances of making a positive impression and landing the job.

1. Research the Company

Before you go to your interview, take some time to research the company. Learn about their history, their products or services, and their culture. This will help you to answer questions intelligently and show that you are interested in the company.

2. Practice Your Answers

It is important to practice your answers to common interview questions before you go to your interview. This will help you to feel more confident and prepared. You can practice your answers with a friend or family member, or you can record yourself and watch it back to see how you come across.

Here are some common Foundry Worker interview questions3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the workplace. You should also avoid wearing excessive jewelry or makeup.

4. Be On Time

Punctuality is important for any job interview, but it is especially important for a Foundry Worker interview. This is because Foundry Workers are often required to work in a fast-paced environment, and employers want to know that you can be on time and reliable.

5. Be Enthusiastic

Foundry Workers play an important role in the manufacturing process, so it is important for them to be enthusiastic about their work. In your interview, you should be able to convey your passion for the job and your desire to learn more about the industry.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Foundry Worker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!