Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Mold Capper position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

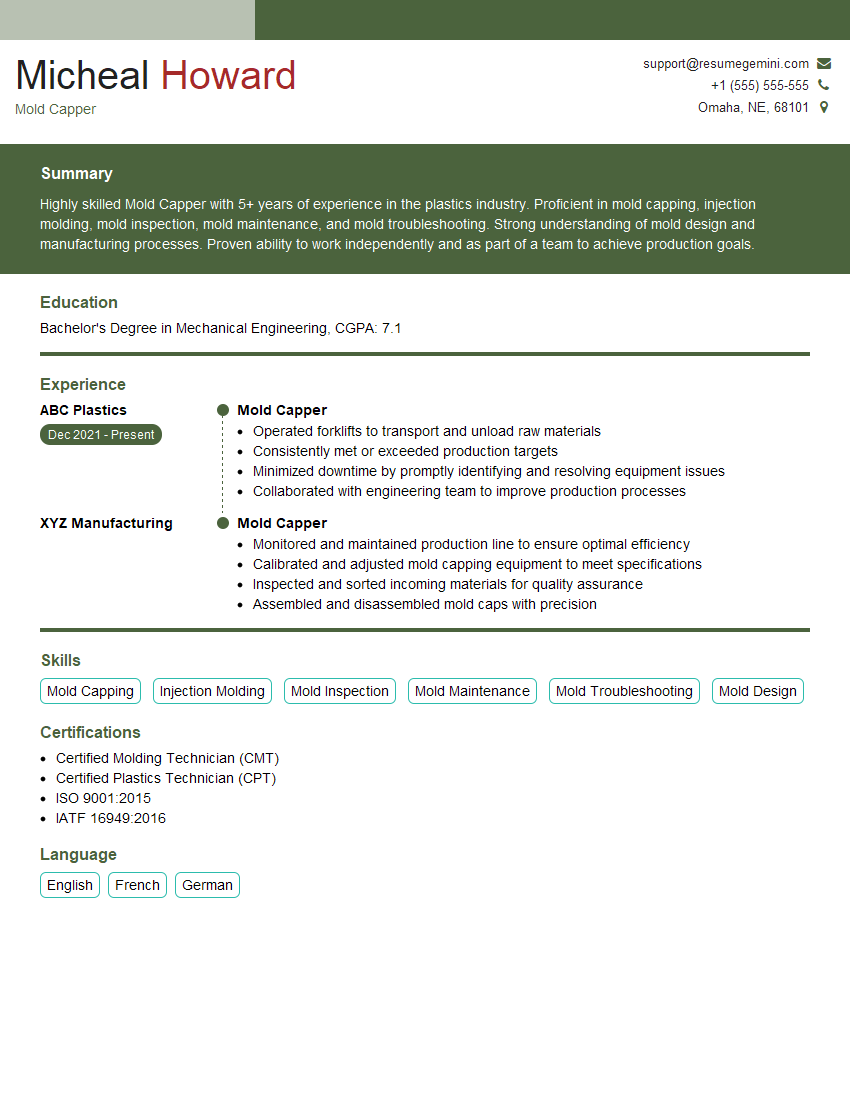

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mold Capper

1. What are the key responsibilities of a Mold Capper?

- Operate mold capping machines to seal plastic containers with aluminum or plastic caps

- Monitor machine performance and make adjustments as needed to ensure proper capping

- Inspect finished products for defects and ensure they meet quality standards

- Clean and maintain capping machines to ensure optimal performance

- Follow safety protocols and wear appropriate personal protective equipment

2. Describe the process of capping a plastic container using a mold capping machine.

Machine Preparation:

- Inspect the capping machine and ensure it is clean and functioning properly

- Load the machine with appropriate caps and containers

Capping Process:

- Place the container under the capping head

- Activate the capping cycle, which will lower the capping head and apply pressure to the cap

Post-Capping Inspection:

- Remove the capped container from the machine

- Inspect the container for any defects or leaks

3. How do you maintain a mold capping machine to ensure optimal performance?

- Regularly clean the capping head and other machine components to remove any debris or contamination

- Lubricate moving parts as per the manufacturer’s recommendations

- Inspect the capping head for wear or damage and replace as necessary

- Perform regular maintenance checks to identify and resolve any potential issues

4. What are some common troubleshooting procedures for mold capping machines?

Capping head not applying enough pressure:

- Check the air pressure supply and ensure it meets the machine’s requirements

- Inspect the capping head for any damage or wear

Capping head not aligning correctly:

- Adjust the capping head alignment using the machine’s controls

- Check the container for any defects or irregularities that may be affecting alignment

5. What safety measures should be taken when operating a mold capping machine?

- Wear appropriate personal protective equipment, including gloves, safety glasses, and earplugs

- Keep hands and loose clothing away from moving machine parts

- Follow lockout/tagout procedures when performing maintenance or repairs

- Be aware of the machine’s operating limits and avoid overloading it

- Report any unsafe conditions or malfunctions to a supervisor immediately

6. What is the difference between a mold capper and a snap capper?

- Mold cappers use a mold to apply pressure to the cap, which results in a tight seal

- Snap cappers use a snapping action to apply the cap, which is less precise and may not result in a as tight a seal as a mold capper

7. How do you determine the appropriate cap size for a given container?

- Measure the diameter of the container’s opening

- Refer to the manufacturer’s specifications to determine the appropriate cap size

- Consider the type of product being packaged and the desired level of seal

8. What are some of the challenges you have encountered as a Mold Capper?

Equipment malfunctions:

- Unexpected breakdowns or errors that require troubleshooting and repair

Product quality issues:

- Ensuring that caps are applied correctly and containers are sealed properly

Production targets:

- Meeting or exceeding daily production goals while maintaining quality standards

9. What are your strengths and weaknesses as a Mold Capper?

Strengths:

- Proficient in operating and maintaining mold capping machines

- Excellent attention to detail and quality control

- Strong troubleshooting and problem-solving abilities

- Ability to work independently and as part of a team

Weaknesses:

- Limited experience with specific types of capping machines (if applicable)

- Occasional difficulty in meeting high production targets during peak periods

- Working in a fast-paced and demanding environment

10. Why are you interested in this Mold Capper position?

- Excited about the opportunity to contribute to your company’s success

- Confident that my skills and experience would make me a valuable asset to your team

- Eager to learn and grow within the organization

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mold Capper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mold Capper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mold Cappers are responsible for operating and maintaining capping machines that apply closures to bottles, jars, or other containers. They may also be responsible for inspecting containers for defects, and for cleaning and sanitizing equipment. Key job responsibilities include:

1. Maintaining and Operating Capping Machines

Mold Cappers are responsible for operating and maintaining capping machines that apply closures to bottles, jars, or other containers. They must be able to troubleshoot mechanical problems and make necessary adjustments to ensure that the machines are operating properly.

- Operate capping machines to apply closures to containers

- Adjust machine settings to ensure proper closure application

- Troubleshoot and repair mechanical problems

- Clean and maintain capping machines

2. Inspecting Containers for Defects

Mold Cappers are responsible for inspecting containers for defects before they are capped. They must be able to identify and reject any containers that are damaged or otherwise unsuitable for capping.

- Inspect containers for defects such as cracks, chips, or foreign objects

- Reject containers that are damaged or unsuitable for capping

- Maintain a clean and sanitary work area

3. Cleaning and Sanitizing Equipment

Mold Cappers are responsible for cleaning and sanitizing capping machines and other equipment on a regular basis. They must be able to follow established cleaning and sanitizing procedures to ensure that the equipment is safe for use.

- Clean and sanitize capping machines and other equipment

- Follow established cleaning and sanitizing procedures

- Maintain a clean and sanitary work area

4. Other Responsibilities

In addition to the above, Mold Cappers may also be responsible for performing other tasks, such as:

- Loading and unloading containers

- Monitoring production lines

- Performing quality control checks

Interview Tips

Preparing for an interview can be stressful, but there are several things you can do to improve your chances of success. Here are some tips:

1. Research the Company and Position

Take some time to learn about the company you are interviewing with, as well as the specific position you are applying for. This will help you to better understand the company’s culture and values, and to tailor your answers to the interviewer’s questions.

2. Practice Your Answers

Think about the questions you are likely to be asked in an interview, and practice your answers. This will help you to feel more confident and prepared during the interview.

3. Dress Professionally

First impressions matter, so make sure to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the workplace.

4. Arrive on Time

Punctuality is important, so make sure to arrive for your interview on time. If you are running late, call the interviewer to let them know.

5. Be Enthusiastic and Positive

Interviewers are looking for candidates who are enthusiastic about the position and the company. Be positive and upbeat during your interview, and show the interviewer that you are genuinely interested in the job.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mold Capper interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!