Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Journeyman Molder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

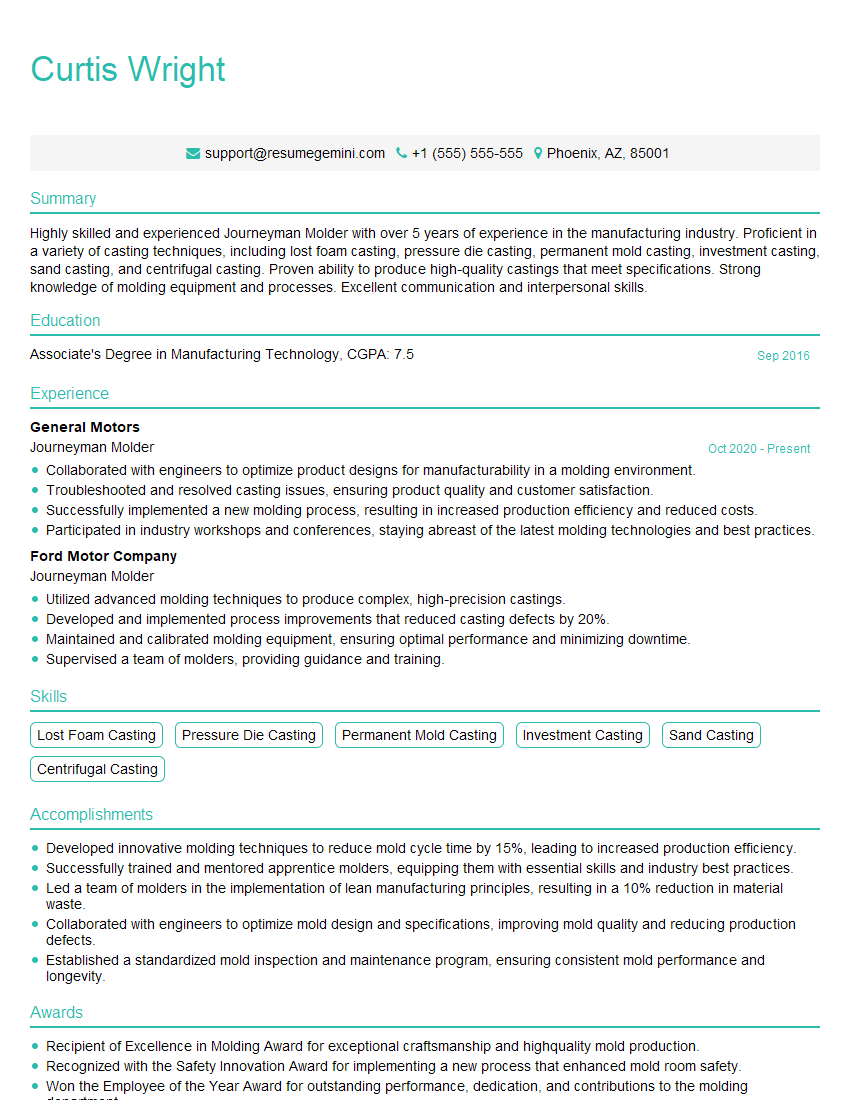

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Journeyman Molder

1. What are the different types of molding processes used in the industry? Describe the steps involved in each process.

There are various molding processes used in the industry, each with its own steps and techniques. Here are a few common types:

- Sand casting: involves creating a mold cavity in sand, pouring molten metal into the cavity, and allowing it to cool and solidify.

- Investment casting: involves creating a wax pattern of the desired object, investing it in a ceramic slurry, and then burning out the wax, leaving a mold cavity that is filled with molten metal.

- Permanent mold casting: involves using a permanent mold made of metal or ceramic, into which molten metal is poured and allowed to solidify.

- Die casting: involves forcing molten metal under high pressure into a die cavity, creating a precise shape.

- Centrifugal casting: involves pouring molten metal into a rotating mold, using centrifugal force to distribute the metal evenly.

2. Explain the importance of gating and risering in a casting process.

Gating

- Gating refers to the system of channels and passages that allow molten metal to flow into the mold cavity.

- Proper gating design ensures efficient filling of the mold and minimizes turbulence, dross formation, and casting defects.

Risering

- Risers are reservoirs of molten metal that are added to the casting to compensate for shrinkage as the metal solidifies.

- Proper riser placement and sizing help prevent shrinkage cavities and ensure the soundness of the casting.

3. Describe the different types of molding materials and their properties.

Molding materials vary in their composition, properties, and suitability for different casting processes. Common types include:

- Sand: Natural or synthetic sand mixed with binders to create a mold cavity.

- Investment materials: Ceramic slurries or powders that are invested around a wax pattern to create a mold cavity.

- Metal molds: Permanent molds made of metal, typically used for high-volume production.

- Die materials: High-strength materials used to create dies for die casting.

4. Explain the factors that affect the dimensional accuracy of a casting.

Dimensional accuracy in casting is influenced by several factors, including:

- Mold design and construction

- Molding materials and their properties

- Metal composition and pouring temperature

- Cooling rate and solidification characteristics

- Pattern shrinkage and distortion

5. Describe the different types of casting defects and their causes.

Casting defects can arise due to various factors during the molding and casting process. Common types include:

- Shrinkage cavities: Caused by insufficient feeding of molten metal during solidification.

- Porosity: Caused by entrapped gases or voids within the metal.

- Cracks: Caused by thermal stresses or improper cooling.

- Inclusions: Caused by foreign materials or impurities in the metal or mold.

- Cold shuts: Caused by incomplete fusion of metal during pouring.

6. Explain the importance of quality control in the molding and casting process.

Quality control is crucial in ensuring the integrity and performance of castings. It involves:

- Establishing and maintaining process standards

- Monitoring and testing raw materials and mold materials

- Inspecting castings for defects

- Implementing corrective actions to address quality issues

- Continuous improvement through analysis and data collection

7. Describe the role of automation in the molding and casting industry.

Automation plays a significant role in modern molding and casting operations, improving efficiency, productivity, and consistency. Automation includes:

- Automated mold handling and pouring systems

- Computer-controlled molding machines

- Robotic systems for inspection and finishing

- Automated data collection and process monitoring

8. Explain the environmental considerations in the molding and casting process.

Environmental considerations are crucial in the molding and casting industry. These include:

- Waste management: Proper disposal of spent molding materials, binders, and metal scrap.

- Emission control: Minimizing harmful emissions from furnaces, pouring operations, and mold release agents.

- Energy efficiency: Optimizing energy consumption in furnaces, molding machines, and other equipment.

- Recycling: Utilizing recycled materials in molding and casting processes.

9. Describe the importance of safety in the molding and casting industry.

Safety is paramount in the molding and casting industry, involving:

- Proper handling of molten metal and potential hazards

- Use of personal protective equipment (PPE)

- Maintaining a clean and organized work environment

- Regular safety training and inspections

- Emergency response procedures

10. What are the career advancement opportunities for a Journeyman Molder?

Career advancement opportunities for a Journeyman Molder include:

- Molding Supervisor: Overseeing mold making operations, managing a team of molders, and ensuring quality standards.

- Casting Supervisor: Supervising casting operations, managing production schedules, and troubleshooting casting defects.

- Quality Control Inspector: Inspecting castings for defects, maintaining quality records, and implementing corrective actions.

- Process Engineer: Developing and optimizing molding and casting processes, improving efficiency and reducing costs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Journeyman Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Journeyman Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Journeyman Molders are responsible for the production of castings. They use various techniques to shape molten metal into the desired forms.

1. Pattern and Mold Preparation

Journeyman Molders interpret engineering drawings and specifications to create patterns and molds. They select the appropriate materials and equipment for the job, and ensure that the molds are properly prepared for casting.

- Analyzing engineering drawings and specifications to understand the casting requirements.

- Selecting the appropriate materials and equipment for mold making, including mold materials, binders, and release agents.

- Constructing patterns and molds using various techniques, such as handcrafting, machine molding, and investment casting.

- Ensuring that molds are properly prepared for casting, including cleaning, applying release agents, and preheating.

2. Casting and Finishing

Journeyman Molders operate casting equipment to pour molten metal into molds. They oversee the casting process and make adjustments as needed. They also perform finishing operations on the castings, such as removing excess metal and smoothing surfaces.

- Operating casting equipment, such as furnaces, ladles, and casting machines.

- Pouring molten metal into molds and ensuring proper filling and solidification.

- Monitoring the casting process and making adjustments to casting parameters, such as temperature, pressure, and cooling rates.

- Performing finishing operations on castings, such as grinding, polishing, and heat treatment.

3. Quality Control and Maintenance

Journeyman Molders inspect castings for defects and ensure that they meet specifications. They also perform routine maintenance on casting equipment and troubleshoot any problems that may arise.

- Inspecting castings for defects and ensuring that they meet specifications, using measuring tools and quality control procedures.

- Performing routine maintenance on casting equipment, including cleaning, lubrication, and adjustments.

- Troubleshooting and resolving any problems that may arise during the casting process.

- Maintaining a clean and organized work area to ensure safety and efficiency.

Interview Preparation Tips

1. Research the Company and Position

Before you go on an interview, it is important to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals. It will also help you prepare for questions about your skills and experience that are relevant to the position.

- Visit the company’s website and read about their history, products, and services.

- Read industry news and articles to stay up-to-date on the latest trends and technologies.

- Talk to people in your network who work in the same industry or at the same company.

2. Practice Your Answers to Common Interview Questions

There are many common interview questions that you should be prepared to answer, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

- Develop a brief, concise answer to the question “Tell me about yourself” that highlights your skills and experience.

- Practice answering questions about your strengths and weaknesses, and be prepared to give specific examples.

- Prepare answers to questions about your experience with specific casting techniques or equipment.

3. Be Prepared to Talk About Your Experience and Skills

The interviewer will want to know about your experience and skills, so be prepared to talk about your work history and what you have accomplished in your previous roles. You should also be able to explain how your skills and experience match the requirements of the position.

- Highlight your experience with different types of casting processes, such as sand casting, die casting, and investment casting.

- Emphasize your skills in pattern making, mold making, and finishing operations.

- Quantify your accomplishments and provide specific examples of your success in previous roles.

4. Be Enthusiastic and Show Your Passion for Casting

Casting is a challenging and rewarding field, so it is important to show the interviewer that you are passionate about it. Be enthusiastic about the work you do and express your desire to learn and grow in the field.

- Share your knowledge of the industry and your passion for casting.

- Talk about your career goals and how this position aligns with your aspirations.

- Ask questions about the position and the company to show your interest in the opportunity.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Journeyman Molder, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Journeyman Molder positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.