Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Molder Apprentice interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Molder Apprentice so you can tailor your answers to impress potential employers.

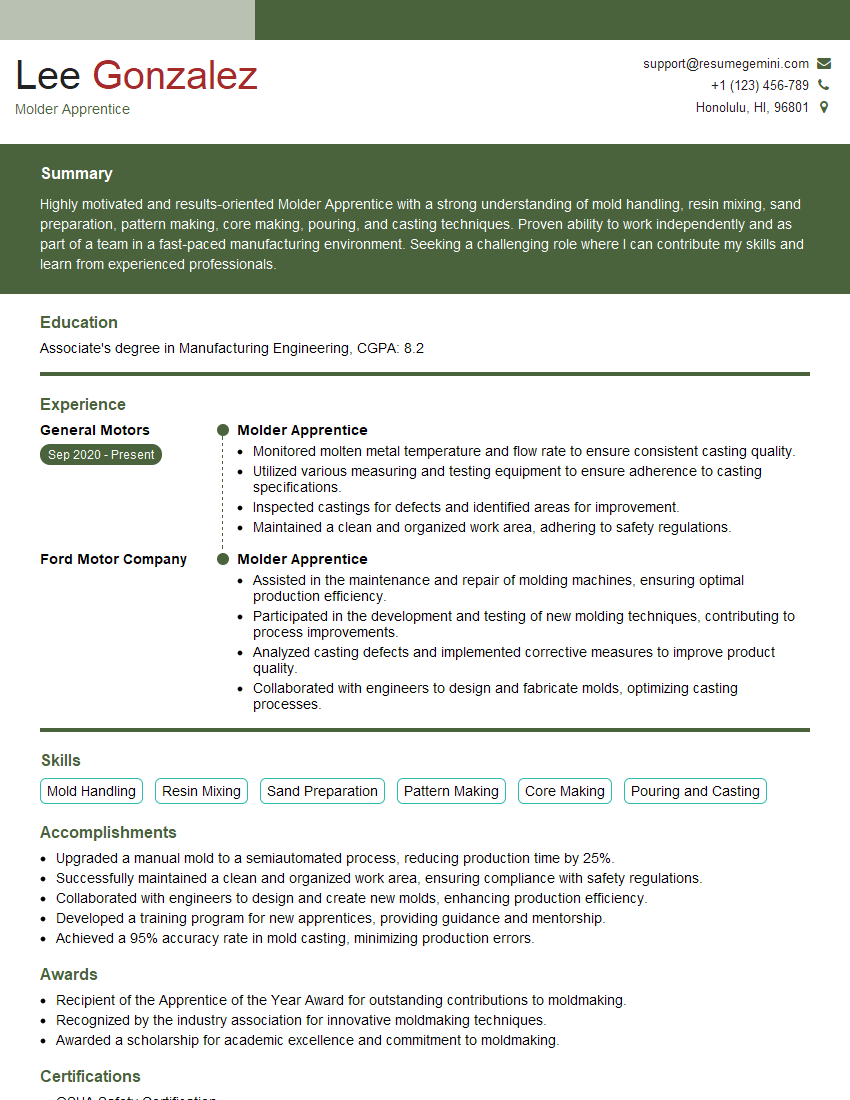

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Molder Apprentice

1. How do you ensure the quality of the molds you create?

- Conduct thorough inspections at each stage of the molding process.

- Utilize precision measuring instruments to verify dimensions and tolerances.

- Employ non-destructive testing methods to identify any potential defects.

- Follow established quality control procedures and specifications.

- Seek feedback from experienced supervisors or colleagues.

2. Describe the different types of molding processes you are familiar with.

Sand Casting

- Green sand molding

- No-bake molding

- Shell molding

Permanent Mold Casting

- Gravity casting

- Pressure casting

- Centrifugal casting

Investment Casting

- Lost wax process

- Ceramic shell process

3. How do you handle situations where the mold does not meet the desired specifications?

- Thoroughly inspect the mold to identify the cause of the discrepancy.

- Consult with experienced supervisors or colleagues for guidance.

- Make necessary adjustments to the molding process or materials.

- Revise the mold design if necessary.

- Document the issue and any corrective actions taken.

4. Describe your experience with different molding materials.

- Sand (green, no-bake, shell)

- Metals (aluminum, iron, steel)

- Plastics (polyurethane, polyethylene, polypropylene)

- Ceramics

- Composites

5. How do you stay up-to-date on the latest technologies and advancements in molding?

- Attend industry conferences and workshops.

- Read trade publications and technical journals.

- Engage in online forums and discussions.

- Pursue continuing education opportunities.

- Network with other professionals in the field.

6. Describe your problem-solving approach when it comes to mold design and creation.

- Identify the root cause of the problem through thorough analysis.

- Generate potential solutions and evaluate their feasibility.

- Implement the most suitable solution and monitor its effectiveness.

- Seek input from colleagues or supervisors as needed.

- Document the problem-solving process for future reference.

7. How do you ensure the safety and accuracy of your molding operations?

- Adhere to established safety protocols and regulations.

- Wear appropriate personal protective equipment.

- Follow proper handling and storage procedures for materials.

- Use calibrated measuring and inspection equipment.

- Conduct regular maintenance and inspections of molding equipment.

8. What are the key factors to consider when selecting the appropriate molding process for a particular application?

- Complexity of the part design

- Material properties

- Production volume

- Cost considerations

- Quality requirements

9. Describe your experience with mold repair and maintenance.

- Conduct regular inspections to identify potential issues.

- Repair minor defects using appropriate techniques.

- Replace damaged or worn components as needed.

- Lubricate and adjust equipment to ensure optimal performance.

- Maintain an organized and clean work area.

10. What are your strengths and weaknesses as a Molder Apprentice?

- Strong attention to detail and precision

- Proficient in various molding processes and materials

- Excellent problem-solving and analytical skills

- Ability to work independently and as part of a team

- Commitment to safety and quality

- Limited experience in certain specialized molding techniques

- Still developing proficiency in mold design software

- Working on improving efficiency in certain aspects of the molding process

- Open to constructive criticism and eager to learn from experienced professionals

Strengths:

Weaknesses:

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Molder Apprentice.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Molder Apprentice‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Molder Apprentice

Molder Apprentices are aspiring professionals who assist skilled Molder professionals in the creation of molded products. Their responsibilities include:

1. Assisting in Molding Operations

Apprentices provide support in various molding processes, such as:

- Preparing and maintaining molds

- Mixing and pouring molding materials

- Operating molding machines

2. Quality Control

Apprentices help ensure the quality of molded products by performing inspections and tests:

- Inspecting molds for defects

- Testing molded products for dimensional accuracy

3. Equipment Maintenance

Apprentices assist in maintaining molding equipment to ensure optimal performance and safety:

- Cleaning and lubricating machinery

- Performing minor repairs

4. Material Handling

Apprentices assist in handling materials used in the molding process efficiently:

- Unloading and storing raw materials

- Loading and unloading molded products

Molder Apprentices work under the supervision of experienced Molders and receive on-the-job training to develop their skills and knowledge.

5. Safety Compliance

Apprentices prioritize adherence to safety regulations in the workplace.

Interview Preparation Tips for Molder Apprentice Candidates

Preparing for an interview as a Molder Apprentice can help you make a strong impression on potential employers. Here are some tips:

1. Research the Company and Position

Familiarize yourself with the company’s profile, industry, and specific role you are applying for. Researching the company’s website, LinkedIn page, and industry news can provide valuable insights.

2. Practice Common Interview Questions

Anticipate common interview questions related to your skills, experience, and motivation for the role. Prepare concise and well-structured answers that highlight your strengths and qualifications.

Example: – “Tell us about your experience in quality control for molding operations?” – “How do you handle working in a fast-paced manufacturing environment?”3. Highlight Your Technical Skills

Emphasize your knowledge and hands-on experience in molding processes, including mold preparation, material mixing, and operating molding machines.

Example: – “I am proficient in setting up and operating CNC molding machines, ensuring precision and product quality.”4. Showcase Your Safety Awareness

Demonstrate your understanding of safety protocols and regulations in the manufacturing industry. Highlight your commitment to maintaining a safe work environment.

Example: – “I am well-versed in workplace safety procedures and have received training in hazard identification and risk assessment.”5. Prepare Questions to Ask

Asking thoughtful questions during the interview shows your interest in the company and the role. Prepare questions about the company’s molding processes, growth opportunities, and any specific projects you could contribute to.

Example: – “Can you provide more information about the company’s approach to sustainable molding?” – “What opportunities are there for professional development and career advancement?”Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Molder Apprentice interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!