Are you gearing up for an interview for a Sand Molder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Sand Molder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

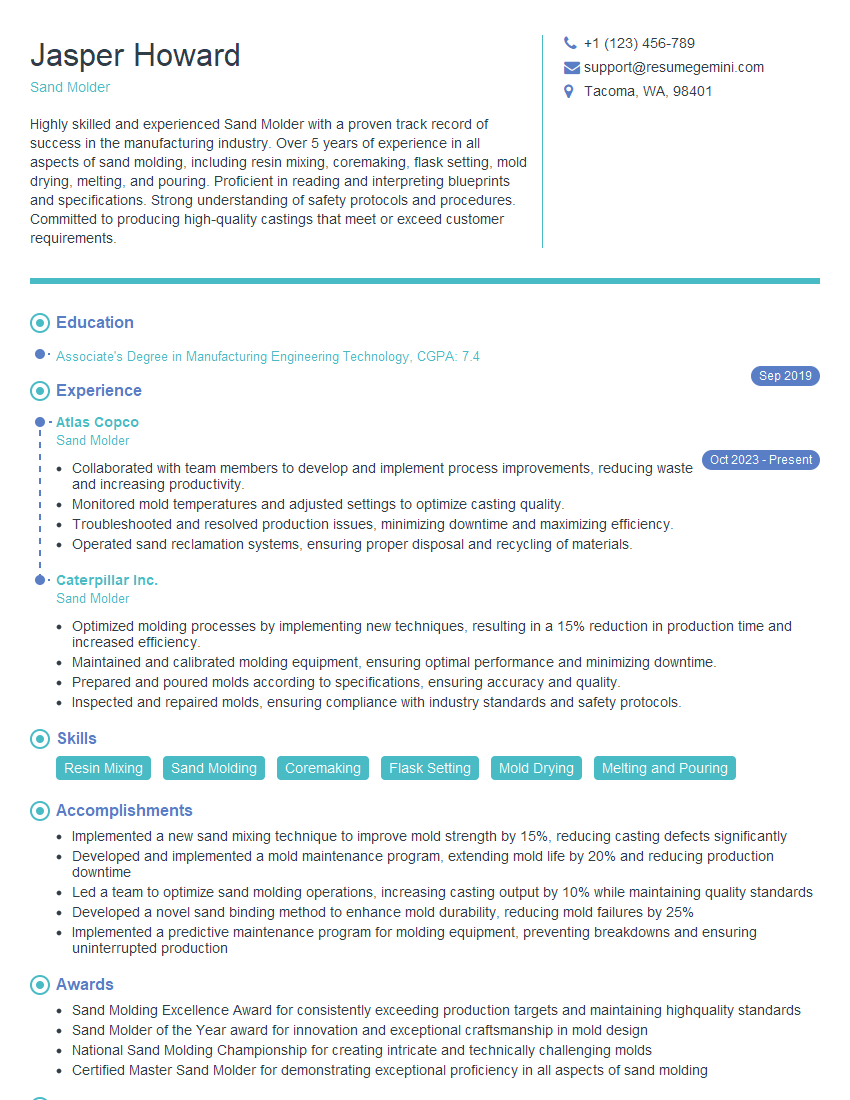

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sand Molder

1. What are the different types of sand used in sand molding?

There are various types of sand used in sand molding, each with its unique properties and applications. Some of the most common types include:

- Silica sand: widely used due to its abundance, affordability, and good molding characteristics.

- Zircon sand: Offers high thermal stability and resistance to molten metal penetration, making it suitable for casting high-temperature alloys.

- Chromite sand: Known for its exceptional resistance to heat and abrasion, primarily used in precision casting.

- Olivine sand: A natural sand with high thermal conductivity and low thermal expansion, making it ideal for casting ferrous metals.

- Chamotte sand: Composed of crushed fireclay, it provides excellent thermal insulation and resistance to molten metal erosion.

2. Describe the process of preparing sand for molding.

Sand Mixing

- Mixing sand with binders (e.g., clay, resins) to create cohesion and strength.

Moisture Addition

- Adding a controlled amount of water to optimize sand workability and moldability.

Sand Conditioning

- Aerating and cooling the sand to remove excess moisture and improve flowability.

3. Explain the different types of molding machines used in sand molding.

- Jolt machines: Uses vertical vibration to pack sand into the mold.

- Squeeze machines: Applies pressure from above to compact the sand.

- Jolt-squeeze machines: Combines both jolting and squeezing actions.

- Rollover machines: Inverts the mold to facilitate pattern removal.

4. What are the defects that can occur in sand molds and how can they be prevented?

Scabs:

- Caused by insufficient sand compaction.

- Prevention: Proper jolting and squeezing.

Veins:

- Result from entrapped air or gas in the sand.

- Prevention: Adequate venting and degassing.

Runouts:

- Occur when molten metal leaks out of the mold.

- Prevention: Proper gating system design and mold integrity.

Shifts:

- Displacement of mold sections during handling.

- Prevention: Proper mold assembly and handling techniques.

5. How do you determine the correct sand-to-binder ratio for a sand mold?

The sand-to-binder ratio is crucial for achieving the desired mold strength and stability. Here’s how to determine the correct ratio:

- Trial and error method: Create test molds with varying sand-to-binder ratios and assess their performance.

- Standard procedures: Refer to established industry standards or manufacturer’s recommendations for specific sand types and binder systems.

- Experience and knowledge: With experience, sand molders can estimate the appropriate ratio based on the type of casting, sand quality, and desired mold properties.

6. What are the safety precautions that must be followed when working with sand molds?

- Wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and respirators.

- Ensure proper ventilation to prevent inhalation of silica dust.

- Handle molds carefully to prevent breakage and potential injuries.

- Follow established safety protocols for handling molten metal.

- Be aware of potential hazards such as hot surfaces and sharp edges.

7. How do you troubleshoot common problems that occur during sand molding?

- Sand sticking to the pattern: Adjust release agents or sand moisture content.

- Rough mold surface: Use finer sand or improve sand conditioning.

- Pattern deformation: Reinforce the pattern or adjust the molding pressure.

- Mold collapse: Increase sand strength by adjusting the sand-to-binder ratio or using stronger binders.

- Gas porosity in casting: Improve venting in the mold or use degassing agents in the sand.

8. What are the different types of cores used in sand molding and their applications?

Green sand cores:

- Made from uncured sand and binders.

- Used for simple shapes and low-temperature applications.

Dry sand cores:

- Baked to harden the sand and binders.

- Suitable for complex shapes and high-temperature applications.

Shell cores:

- Coated with a thin resin shell.

- Provide excellent surface finish and dimensional accuracy.

Oil sand cores:

- Bonded with oil-based binders.

- Used for large and heavy castings.

9. How do you maintain and care for sand molding equipment?

- Regularly inspect and clean equipment to remove sand and debris.

- Lubricate moving parts and check for wear and tear.

- Calibrate equipment regularly to ensure accuracy and precision.

- Follow manufacturer’s instructions for maintenance and repair.

10. Describe your experience in sand molding and highlight your strengths and weaknesses.

In my previous role as a Sand Molder, I gained extensive experience in all aspects of sand molding, including sand preparation, mold making, core setting, and casting. My strengths lie in my ability to produce high-quality molds with precision and efficiency. I am also proficient in troubleshooting common problems and ensuring the smooth operation of molding equipment. However, I acknowledge that I could further develop my skills in advanced molding techniques, such as shell molding and investment casting.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sand Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sand Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sand Molders, also known as Mold Makers, play a crucial role in the metal casting industry. Their primary responsibility is to create sand molds used to cast metal components. These molds are essential for shaping molten metal into desired forms and dimensions.

1. Mold Preparation

Sand Molders prepare sand molds by following blueprints and specifications. They select the appropriate sand mixture, prepare the mold box, and compact the sand to create a cavity that matches the desired shape of the metal casting.

- Select and mix different types of sand to achieve the desired mold properties.

- Build and assemble mold boxes to hold the sand mold.

- Compact the sand using hand tools, machines, or vibration techniques to create a dense and durable mold.

2. Pattern Placement and Removal

Molders place patterns, which are physical representations of the desired casting, into the mold cavity. They carefully position the patterns and ensure they are securely held in place.

- Handle and manipulate patterns with precision and care.

- Apply parting agents to prevent sticking between the pattern and the mold.

3. Gating and Risering

Molders create gating systems and risers in the mold to control the flow of molten metal during casting. Gating systems allow the molten metal to enter the mold cavity while risers provide additional metal to compensate for shrinkage during solidification.

- Design and create gating systems to optimize metal flow and minimize defects.

- Install risers at strategic locations to ensure sufficient metal supply and prevent shrinkage cavities.

- Calculate and adjust gating and riser dimensions based on casting size and metal properties.

4. Mold Finishing and Pouring

After mold preparation, Molders finish the mold by removing patterns, closing the mold box, and applying coatings or dressings. They then assist in pouring molten metal into the mold.

- Inspect and repair any imperfections in the mold before closing.

- Apply coatings or dressings to improve mold surface quality and prevent defects.

- Coordinate with foundry workers to pour molten metal into the mold safely and efficiently.

Interview Tips

To ace an interview for a Sand Molder position, it is essential to prepare thoroughly. Here are some tips and hacks to help you stand out:

1. Research the Company and Industry

Before the interview, take the time to research the company and the foundry industry. Learn about their products, services, and processes. This knowledge will demonstrate your interest and enthusiasm for the role.

2. Practice Technical Skills

Sand Molders need strong technical skills in mold preparation, gating and risering, and metal casting processes. Brush up on these concepts and be prepared to discuss your experience and knowledge in detail.

3. Highlight Safety and Quality

Safety and quality are paramount in the foundry industry. Emphasize your commitment to following safety protocols and your attention to detail in creating high-quality molds.

4. Show Teamwork and Communication Skills

Sand Molders often work in teams and collaborate with other foundry workers. Showcase your ability to communicate effectively, work with others, and contribute to a positive work environment.

Next Step:

Now that you’re armed with the knowledge of Sand Molder interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Sand Molder positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini