Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Bench Molder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

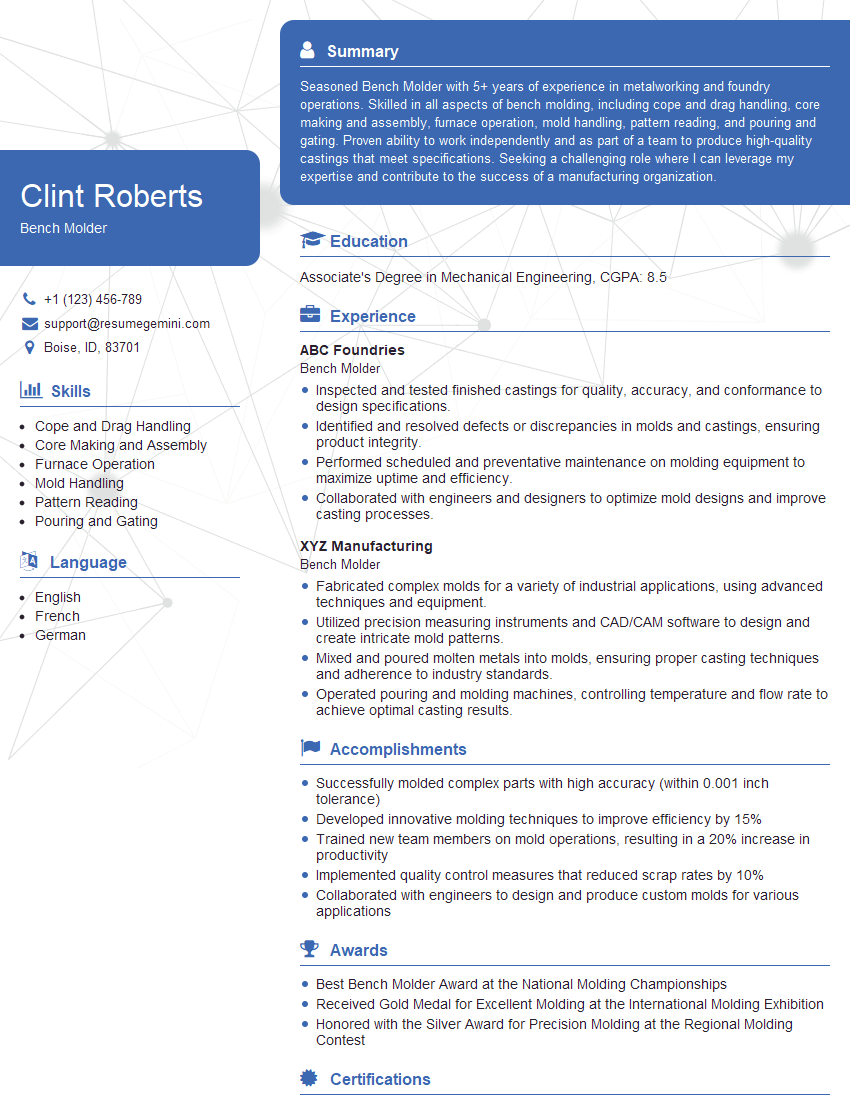

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bench Molder

1. What are the basic steps involved in bench molding?

The basic steps involved in bench molding are:

- Preparing the molding sand.

- Making the pattern.

- Ramming the sand around the pattern.

- Removing the pattern.

- Pouring the molten metal into the mold.

- Allowing the metal to cool and solidify.

- Breaking the mold and removing the casting.

2. What are the different types of molding sand?

Green sand

- Green sand is a mixture of sand, clay, and water.

- It is the most common type of molding sand used in bench molding.

Dry sand

- Dry sand is a mixture of sand and a binder, such as resin or oil.

- It is used for making molds that require a high degree of accuracy.

Loam sand

- Loam sand is a mixture of sand, clay, and silt.

- It is used for making molds that require a high degree of strength.

3. What are the different types of patterns used in bench molding?

- Single-piece patterns

- Split patterns

- Cope and drag patterns

- Gated patterns

4. What are the different types of gates used in bench molding?

- Sprue gates

- Ingate gates

- Runner gates

- Riser gates

5. What are the different types of risers used in bench molding?

- Open risers

- Blind risers

- Feeder risers

6. What are the different types of chills used in bench molding?

- Internal chills

- External chills

7. What are the different types of defects that can occur in bench molding?

- Shrinkage

- Porosity

- Cold shuts

- Misruns

- Pinholes

8. What are the different ways to prevent defects in bench molding?

- Using the correct type of molding sand

- Using the correct type of pattern

- Using the correct type of gate

- Using the correct type of riser

- Using the correct type of chill

- Properly ramming the sand

- Properly pouring the molten metal

- Properly cooling and solidifying the metal

9. What are the different types of equipment used in bench molding?

- Molding boxes

- Pattern plates

- Rammers

- Slicks

- Sprue cutters

- Pouring ladles

- Crucibles

- Furnaces

10. What are the different safety precautions that must be taken when bench molding?

- Wear appropriate safety gear, such as gloves, safety glasses, and a dust mask.

- Keep the work area clean and free of tripping hazards.

- Use caution when handling molten metal.

- Be aware of the location of fire extinguishers and other emergency equipment.

- Follow all safety procedures.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bench Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bench Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bench Molders are responsible for creating molds and castings using various materials such as metal, plastic, and rubber. They work with a variety of equipment, including molding machines, injection molding machines, and casting equipment. Key responsibilities include:

1. Mold Preparation

Preparing and maintaining molds and tooling, including cleaning, repairing, and modifying molds as needed.

- Inspecting molds for defects and wear

- Adjusting and calibrating molding equipment

2. Material Handling

Handling and preparing materials for molding and casting, including measuring, mixing, and weighing materials.

- Selecting and preparing appropriate materials

- Monitoring material levels and ensuring proper inventory

3. Molding and Casting

Operating molding and casting equipment to produce molds and castings.

- Setting up and operating molding machines

- Monitoring molding and casting processes

4. Finishing

Finishing and inspecting molds and castings, including removing flash, burrs, and other imperfections.

- Trimming and finishing castings

- Inspecting castings for quality and accuracy

Interview Tips

To ace an interview for a Bench Molder position, consider the following tips:

1. Research the Company and Position

Research the company and the specific role to gain an in-depth understanding of their business, products, and culture. This will help you tailor your answers and demonstrate your interest in the position.

- Visit the company website and social media pages

- Read industry news and articles

2. Practice Your Answers

Prepare thoughtful answers to common interview questions, focusing on highlighting your skills, experience, and qualifications. Practice your answers out loud or with a friend or family member to build confidence and fluency.

- Review job description and identify key responsibilities

- Prepare examples of your work experience and accomplishments

3. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally and arrive on time for your interview. This shows respect for the interviewer and the company, and conveys that you are serious about the opportunity.

- Choose appropriate business attire, such as a suit or dress

- Arrive at the interview location with ample time to spare

4. Be Enthusiastic and Ask Questions

Show your enthusiasm for the position and the company during the interview. Ask thoughtful questions to demonstrate your interest and engagement. This also gives you the opportunity to clarify any details about the role and the company.

- Ask about the company’s growth plans and industry outlook

- Inquire about the specific responsibilities and expectations of the role

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bench Molder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!