Feeling lost in a sea of interview questions? Landed that dream interview for Bonding Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Bonding Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

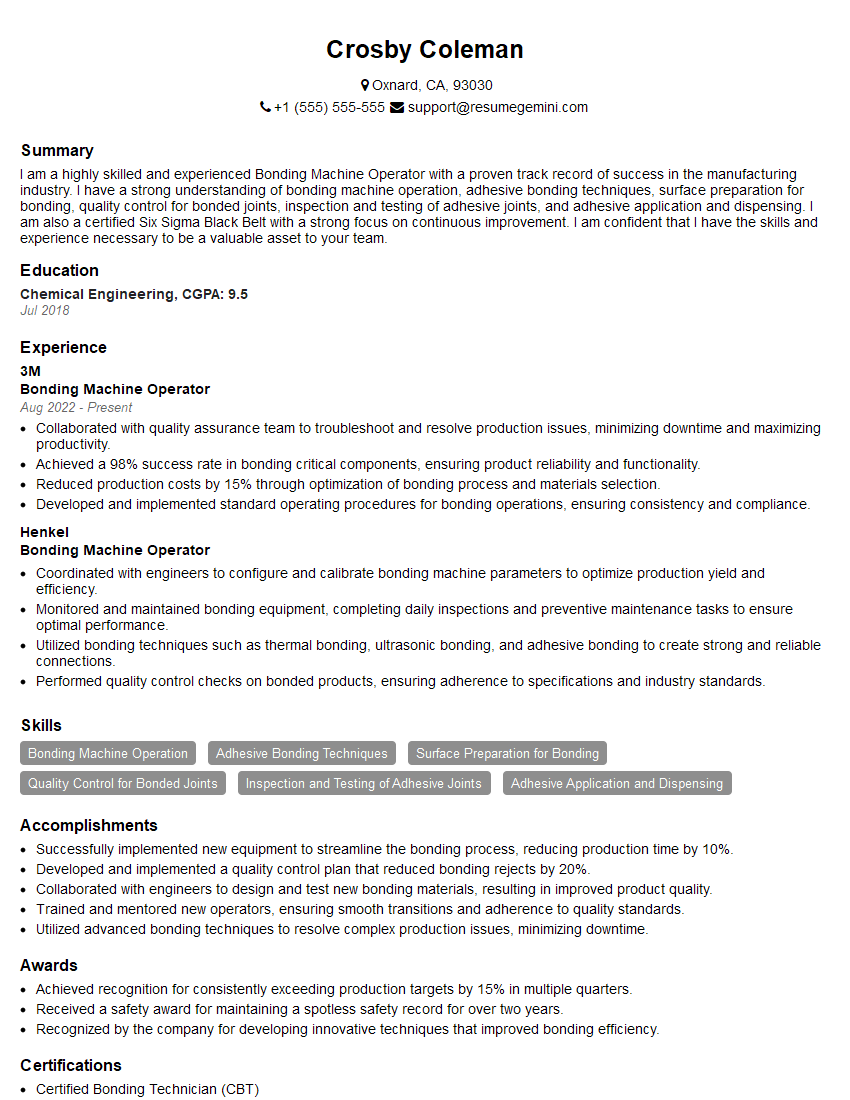

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bonding Machine Operator

1. Explain the process of setting up a bonding machine?

I start by inspecting the machine to ensure it is clean and in good working order. I verify that all necessary tools are available, including bonding fixtures, adhesives, cleaning supplies, and personal protective equipment. I then load the bonding materials and adjust the machine settings according to the manufacturer’s instructions and the specific bonding requirements.

2. How do you troubleshoot common bonding machine issues?

Mechanical Problems

- Inspect the machine for any loose or damaged parts.

- Check if the bonding head is aligned correctly.

- Calibrate the machine to ensure accuracy.

Electrical Problems

- Check if the machine is properly connected to a power source.

- Inspect the electrical wiring for any damage or loose connections.

- Test the electrical components, such as sensors and actuators.

3. What types of bonding processes have you experience with?

- Thermal Bonding

- Ultrasonic Bonding

- Solvent Bonding

- Chemical Bonding

- Laser Bonding

4. Describe the quality control procedures you follow during the bonding process?

- Visual Inspection

- Bond Strength Testing

- Dimensional Verification

- Adhesion Testing

- Environmental Testing

5. What are the safety precautions you take when working with bonding machines?

- Wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and earplugs.

- Operate the machine in a well-ventilated area.

- Handle chemicals and adhesives with care.

- Keep the work area clean and organized.

- Follow all manufacturer’s safety instructions.

6. What is the importance of precision and accuracy in bonding?

- Ensures proper functionality and performance of bonded components.

- Prevents leaks, failures, and other defects.

- Maintains the integrity of the bonded products.

- Reduces production costs by minimizing rework and scrap.

7. How do you calibrate and maintain a bonding machine?

I follow a regular maintenance schedule to ensure optimal machine performance and accuracy. The calibration process involves comparing the machine’s readings to a known standard and adjusting the settings accordingly. I also perform routine checks on the machine’s components, including the bonding head, sensors, and actuators.

8. What are the different types of adhesives used in bonding machines?

- Epoxy Adhesives

- Acrylic Adhesives

- Cyanoacrylate Adhesives

- Hot Melt Adhesives

- Polyurethane Adhesives

9. How do you determine the correct bonding temperature and time?

- Refer to the manufacturer’s specifications for the adhesive being used.

- Conduct trial bonds to determine the optimal temperature and time settings.

- Consider the materials being bonded and their properties.

10. What is the role of surface preparation in bonding?

- Removes contaminants and impurities from the bonding surfaces.

- Creates a clean and uniform surface for better adhesion.

- Enhances the bond strength and durability.

11. How do you monitor the bonding process for defects?

- Visual Inspection

- Non-destructive Testing (NDT) Techniques

- Bond Testing Equipment

12. What are some tips for optimizing bonding machine efficiency?

- Proper maintenance and calibration.

- Selecting the right adhesive and bonding parameters.

- Efficient workholding and fixturing.

- Optimizing the bonding cycle time.

13. How do you handle production issues related to bonding?

- Identify the root cause of the issue.

- Implement corrective actions to resolve the problem.

- Monitor the production process to prevent recurrence.

14. What are the latest advancements in bonding technology?

- Laser Bonding

- Induction Bonding

- Automated Bonding Systems

15. How do you stay updated with the latest bonding techniques and industry best practices?

- Attend industry conferences and workshops.

- Read technical journals and publications.

- Network with other professionals in the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bonding Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bonding Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bonding Machine Operators are responsible for operating and maintaining bonding machines used in the manufacturing process. These machines join materials together using adhesives or other bonding agents. The key responsibilities of a Bonding Machine Operator include:

1. Machine Operation

Operate bonding machines to join materials together.

- Set up and calibrate bonding machines.

- Load and unload materials to and from bonding machines.

- Monitor bonding machines and adjust settings as needed.

2. Quality Control

Inspect bonded materials to ensure they meet quality standards.

- Identify and correct defects in bonded materials.

- Maintain records of bonding operations and quality control checks.

- Report any problems with bonding machines or materials to supervisors.

3. Maintenance

Perform basic maintenance on bonding machines.

- Clean and lubricate bonding machines.

- Replace worn or damaged parts.

- Troubleshoot and repair minor problems with bonding machines.

4. Safety

Follow safety procedures when operating bonding machines.

- Wear appropriate personal protective equipment (PPE).

- Operate bonding machines in a safe and efficient manner.

- Report any safety hazards to supervisors.

Interview Tips

Preparing for an interview can be daunting, but by following these tips, you can increase your chances of success.

1. Research the Company and Position

Before you go to an interview, it is important to do your research. Learn about the company’s history, culture, and products or services. You should also research the specific position you are applying for. This will help you to understand the company’s needs and how your skills and experience can benefit them.

- Visit the company’s website.

- Read industry news and articles.

- Talk to people who work at the company.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked. It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

- “Tell me about yourself.”

- “Why are you interested in this position?”

- “What are your strengths and weaknesses?”

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the office environment. You should also make sure that your shoes are polished and that your hair is neat.

4. Be Punctual

Punctuality shows that you are respectful of the interviewer’s time. Aim to arrive at your interview 5-10 minutes early so that you have time to check in and get settled.

5. Be Yourself

It is important to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be honest and authentic, and let your personality shine through.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bonding Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.