Are you gearing up for an interview for a Blow Molding Machine Tender position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Blow Molding Machine Tender and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

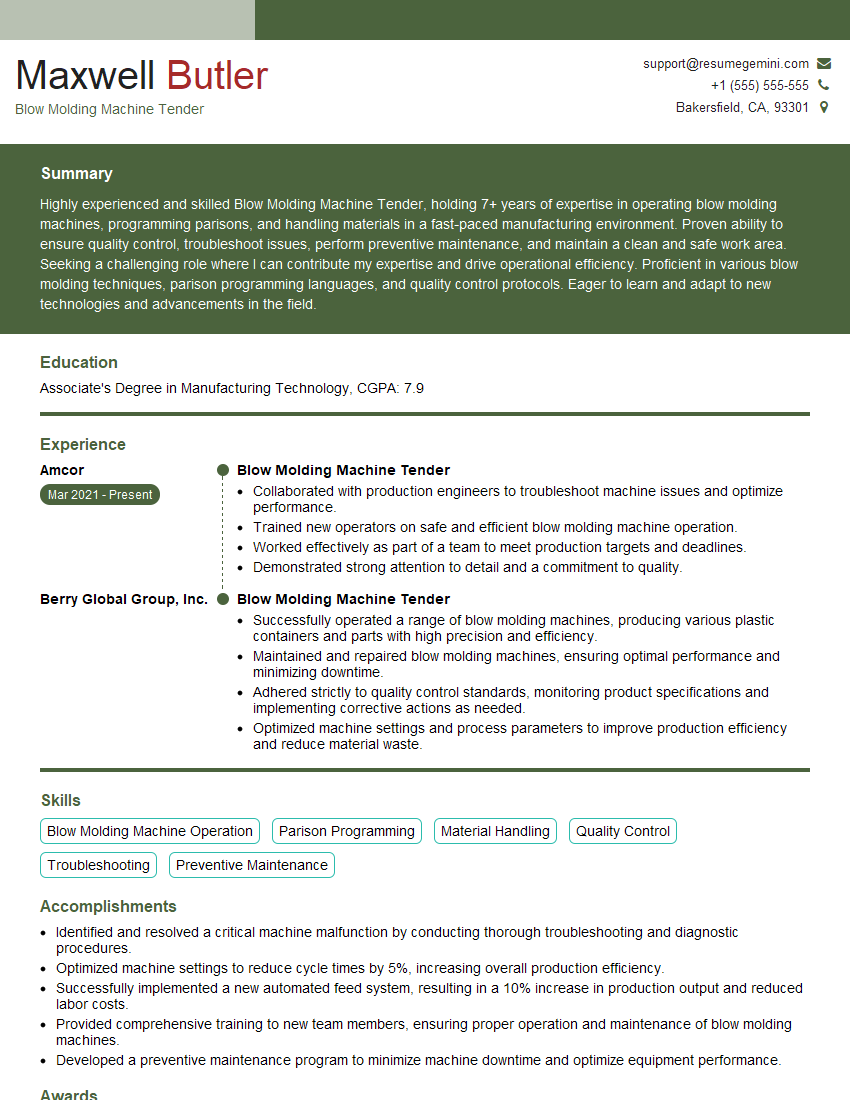

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Blow Molding Machine Tender

1. Describe the process of blow molding?

Answer

- Step 1: Clamp Closure – The mold halves are closed and clamped together.

- Step 2: Extrusion – Molten plastic is extruded from a die into a parison (a tube).

- Step 3: Blow Molding – Compressed air is used to inflate the parison, which takes the shape of the mold.

- Step 4: Cooling – The plastic cools and solidifies.

- Step 5: Mold Opening – The mold halves open and the finished product is ejected.

2. What are the different types of blow molding machines?

Answer

- Used to produce hollow plastic containers with a wide range of sizes and shapes.

- The parison is extruded vertically.

- Used for small, complex-shaped containers.

- The parison is injected into the mold horizontally.

Extrusion Blow Molding (EBM)

Injection Blow Molding (IBM)

3. What are the safety precautions that must be followed when operating a blow molding machine?

Answer

- Wear appropriate safety gear, including goggles, gloves, and hearing protection.

- Keep the machine clean and well-maintained.

- Never reach into the mold area while the machine is operating.

- Be aware of the risks of fire and explosion.

- Follow all safety protocols and procedures.

4. What are the common problems that can occur with blow molding machines?

Answer

- Flash – Excess plastic that forms around the mold parting line.

- Sink marks – Indentations in the plastic caused by cooling too quickly.

- Warping – Distortion of the plastic caused by uneven cooling or shrinkage.

- Bubbles – Small air pockets trapped in the plastic.

- Cracks – Breaks in the plastic caused by excessive stress or improper cooling.

5. How do you troubleshoot problems with blow molding machines?

Answer

- Identify the problem and gather information about its symptoms.

- Check the machine for any obvious problems, such as leaks or broken parts.

- Refer to the machine’s troubleshooting guide or consult with a qualified technician.

- Make adjustments or repairs as necessary.

- Monitor the machine’s performance to ensure the problem has been resolved.

6. How do you maintain a blow molding machine?

Answer

- Lubricate the machine regularly.

- Clean the mold and other components regularly.

- Inspect the machine for any signs of wear or damage.

- Perform regular preventive maintenance tasks.

- Keep a maintenance log and record all maintenance activities.

7. How do you set up a blow molding machine for production?

Answer

- Install the mold in the machine.

- Set the machine parameters, such as the temperature, pressure, and cycle time.

- Load the plastic material into the machine.

- Start the machine and monitor its performance.

- Make adjustments as necessary to ensure the machine is producing quality products.

8. How do you optimize the performance of a blow molding machine?

Answer

- Use the correct mold temperature and pressure settings.

- Use the correct cycle time.

- Use the correct plastic material.

- Maintain the machine properly.

- Monitor the machine’s performance and make adjustments as necessary.

9. How do you handle waste produced by a blow molding machine?

Answer

- Collect the waste in a designated area.

- Recycle the waste if possible.

- Dispose of the waste in a safe and environmentally responsible manner.

10. How do you stay up-to-date on the latest blow molding technologies?

Answer

- Attend industry trade shows and conferences.

- Read industry publications.

- Network with other blow molding professionals.

- Take training courses.

- Stay informed about the latest equipment and materials.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Blow Molding Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Blow Molding Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Blow Molding Machine Tender is responsible for operating and maintaining blow molding machines, which are used to create plastic products by injecting molten plastic into a mold and then blowing air into the mold to form the product. Key job responsibilities include:

1. Machine Operation

Operating blow molding machines to produce plastic products, such as bottles, containers, and toys.

- Monitoring machine settings, such as temperature, pressure, and cycle time, to ensure proper operation.

- Adjusting machine settings as needed to maintain product quality and efficiency.

2. Production Quality

Inspecting products for defects and taking corrective action as needed.

- Performing quality control checks on products to ensure they meet specifications.

- Identifying and resolving production issues to minimize downtime and maintain product quality.

3. Maintenance and Repair

Performing preventative maintenance on blow molding machines, such as cleaning, lubricating, and inspecting.

- Inspecting equipment for wear and tear, and making minor repairs as needed.

- Reporting major maintenance issues to supervisors for timely resolution.

4. Safety and Compliance

Following safety procedures and adhering to environmental regulations.

- Wearing appropriate safety gear, such as safety glasses and gloves.

- Complying with all applicable safety regulations and environmental standards.

Interview Tips

To ace an interview for a Blow Molding Machine Tender position, it’s important to:

1. Research the Company and Role

Familiarize yourself with the company’s products, services, and culture. Research the specific role and its responsibilities.

- Visit the company’s website and social media pages to gather information.

- Read industry-related publications and articles to gain insights into the field.

2. Highlight Relevant Experience and Skills

Emphasize your experience in operating blow molding machines and performing related tasks. Quantify your accomplishments and provide specific examples.

- Describe situations where you identified and resolved production issues, resulting in improved efficiency or reduced downtime.

- Showcase your attention to detail and ability to maintain a clean and organized work area.

3. Demonstrate Safety and Compliance Knowledge

Demonstrate your understanding of safety procedures and environmental regulations related to blow molding operations.

- Explain the importance of wearing appropriate safety gear and following established safety protocols.

- Describe your experience in adhering to environmental standards, such as waste management and emissions control.

4. Be Prepared for Technical Questions

Expect questions about the operation and maintenance of blow molding machines. Be prepared to discuss topics such as machine settings, troubleshooting techniques, and preventative maintenance procedures.

- Review common machine malfunctions and the steps involved in diagnosing and repairing them.

- Familiarize yourself with the principles of blow molding technology and the different types of machines used in the industry.

5. Practice Your Responses

Prepare for common interview questions and practice your responses in advance. This will help you feel confident and articulate during the interview.

- Consider using the STAR method (Situation, Task, Action, Result) to structure your answers.

- Ask a friend or family member to conduct a mock interview and provide feedback.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Blow Molding Machine Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!