Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Coremaking Machine Setter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

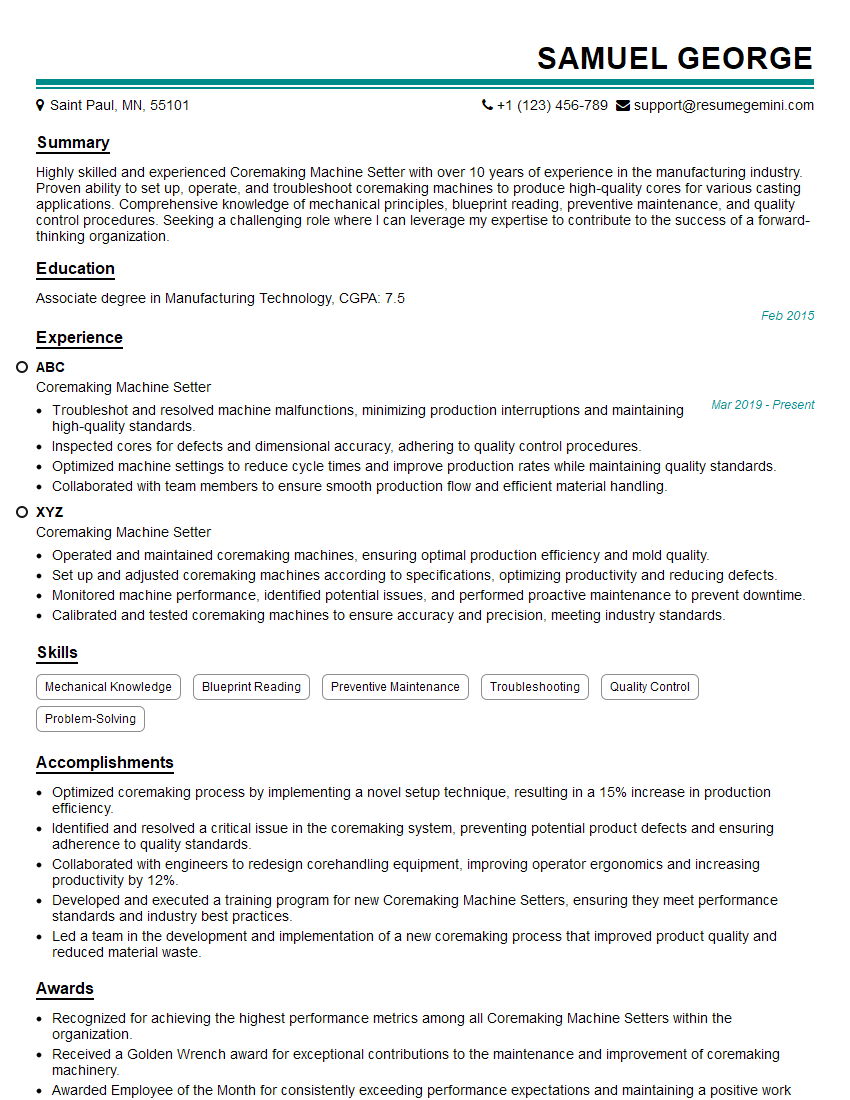

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coremaking Machine Setter

1. Explain the process of setting up a coremaking machine?

The setup process of a coremaking machine involves several steps:

- Preparation: Gather necessary materials, read setup instructions, and ensure safety precautions are in place.

- Machine Inspection: Inspect the machine for cleanliness, lubrication, and any potential issues.

- Pattern Plate Installation: Mount the pattern plate onto the machine, ensuring proper alignment and securing it firmly.

- Core Box Installation: Place the core box onto the pattern plate and secure it using clamps or bolts.

- Sand Hopper Adjustment: Adjust the position and settings of the sand hopper to ensure a consistent flow of sand into the core box.

- Blower Setup: Connect the blower and adjust its settings to provide adequate airflow for sand distribution.

- Pressure Adjustments: Set the blow pressure and squeeze pressure based on the core design and sand properties.

- Test Runs: Perform test runs to verify the correct operation of the machine, make adjustments as needed, and ensure the production of defect-free cores.

2. Describe the different types of coremaking machines and their applications?

There are several types of coremaking machines, each suitable for specific applications:

Types of Coremaking Machines

- Blower Core Machines: Use compressed air to blow sand into the core box.

- Shooter Core Machines: Use a reciprocating motion to shoot sand into the core box.

- Rotary Core Machines: Use a rotating table to distribute sand uniformly.

Applications

- Blower Core Machines: Small to medium-sized cores with complex shapes.

- Shooter Core Machines: Large cores with simple geometries and high production rates.

- Rotary Core Machines: Cores requiring high dimensional accuracy and consistent quality.

3. What are the key factors to consider when selecting a coremaking machine?

Factors to consider when selecting a coremaking machine include:

- Core Size and Complexity: Determine the size and complexity of the cores to be produced.

- Production Rate: Estimate the desired production rate to meet production demands.

- Sand Properties: Consider the type and properties of the sand used.

- Budget and Space Constraints: Consider the financial resources and space availability.

- Reliability and Maintenance: Assess the machine’s reputation for reliability, maintenance requirements, and parts availability.

- Automation and Integration: Determine the level of automation and integration required.

4. Discuss the importance of proper sand preparation for coremaking processes?

Proper sand preparation is crucial for coremaking processes due to several reasons:

- Core Quality: Well-prepared sand ensures uniform sand distribution, eliminates defects, and improves core strength.

- Machine Efficiency: Properly prepared sand allows for smooth sand flow, reducing machine wear and downtime.

- Consistency: Consistent sand preparation ensures repeatable core properties, reducing the need for adjustments.

- Productivity: Proper sand preparation optimizes blow pressure and squeeze pressure settings, maximizing production efficiency.

- Material Savings: Well-prepared sand minimizes waste and reduces the need for excessive sand binder.

5. What are the common troubleshooting procedures for coremaking machines?

Common troubleshooting procedures for coremaking machines include:

- Sand Flow Issues: Check sand hopper settings, blower pressure, and sand chute blockages.

- Core Defects: Inspect core box for damage, adjust blow pressure and squeeze pressure, and verify sand preparation.

- Mechanical Problems: Perform routine maintenance, check for loose connections, and assess machine components for wear.

- Electrical Faults: Examine wiring, connections, sensors, and electrical components.

- Automation Errors: Verify PLC programming, check sensors and actuators, and review automation sequences.

6. Describe the safety precautions that must be taken when operating a coremaking machine?

Safety precautions for operating coremaking machines include:

- Machine Guarding: Ensure all machine guards are in place and operational.

- Personal Protective Equipment: Wear appropriate PPE, including safety glasses, gloves, and hearing protection.

- Lockout/Tagout Procedures: Follow proper procedures when performing maintenance or repairs.

- Sand Handling: Use proper ventilation and wear respirators to prevent silica dust inhalation.

- Emergency Procedures: Be familiar with emergency stop procedures and evacuation routes.

7. Discuss the role of quality control in coremaking processes?

Quality control is crucial in coremaking processes to ensure:

- Core Dimensions and Tolerances: Verify core dimensions meet specifications using measuring tools.

- Core Strength: Perform core strength tests to ensure cores meet required strength criteria.

- Surface Finish: Inspect cores for defects, blow holes, or surface irregularities.

- Core Permeability: Measure core permeability to ensure proper gas flow during casting.

- Documentation: Maintain records of quality control tests to track process consistency and identify areas for improvement.

8. What are the latest trends and advancements in coremaking technology?

Recent trends in coremaking technology include:

- Automated Coremaking Systems: Integration of robots and automation for improved efficiency and reduced labor requirements.

- 3D Printing for Core Production: Using 3D printing techniques to create complex core geometries with high precision.

- Advanced Sand Binder Systems: Development of new binder systems that enhance core strength and reduce defects.

- Improved Machine Control: PLC-based control systems with advanced monitoring and data acquisition capabilities.

- Sustainable Coremaking Processes: Focus on reducing environmental impact through energy-efficient machines and eco-friendly materials.

9. How do you stay updated with the latest developments in the coremaking industry?

To stay updated with the latest developments in the coremaking industry, I engage in the following practices:

- Industry Publications: Subscribe to industry magazines and journals.

- Conferences and Exhibitions: Attend industry events to network and learn about new technologies.

- Online Resources: Utilize websites, forums, and social media platforms to gather information.

- Collaboration with Suppliers: Consult with suppliers and equipment manufacturers for insights into advancements.

- Continuous Learning: Participate in training programs and workshops to enhance knowledge and skills.

10. What is your approach to continuous improvement in a coremaking environment?

My approach to continuous improvement in a coremaking environment involves:

- Process Analysis: Regularly evaluate coremaking processes to identify inefficiencies and areas for improvement.

- Data Collection and Analysis: Collect and analyze data related to core quality, production efficiency, and machine performance.

- Implementation of Solutions: Propose and implement solutions to address identified issues, such as optimizing machine settings or improving sand preparation.

- Monitoring and Evaluation: Track the effectiveness of implemented solutions and make further adjustments as needed.

- Collaboration: Work with colleagues, engineers, and management to foster a culture of continuous improvement.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coremaking Machine Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coremaking Machine Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Coremaking Machine Setters are responsible for setting up and operating coremaking machines to produce sand cores for metal castings. The primary functions of a Coremaking Machine Setter include but are not limited to:

1.Machine Setup

Set up and calibrate coremaking machines to produce cores according to specifications.

- Inspect machines for proper functioning and make necessary adjustments.

- Load and adjust tooling and fixtures to meet core design requirements.

2.Core Production

Operate coremaking machines to produce sand cores efficiently and safely.

- Control machine settings to ensure proper core formation, density, and curing.

- Monitor production processes to identify and correct any deviations from specifications.

3.Quality Control

Inspect and measure cores to verify they meet quality standards and specifications.

- Use gauges and measuring tools to check core dimensions, shape, and surface finish.

- Identify and report any defects or non-conformities to supervisors.

4.Maintenance

Perform basic maintenance and troubleshooting on coremaking machines.

- Clean and lubricate machines.

- Repair minor breakdowns and replace worn or damaged parts.

Interview Tips

Preparing for an interview for a Coremaking Machine Setter position requires careful research and practice. Here are some tips to help you ace the interview:

1.Research the Company

Before the interview, take the time to research the company and its products or services. This will demonstrate your interest and enthusiasm for the role.

- Visit the company’s website to learn about their history, mission, and current projects.

- Read industry news articles to stay informed about trends and advancements in coremaking technology.

2.Practice Your Answers

It’s helpful to practice answering common interview questions. Prepare brief, concise answers that highlight your relevant skills and experience.

- “Tell me about your experience setting up and operating coremaking machines.”

- “How do you ensure the quality of the cores you produce?”

3.Ask Informed Questions

Prepare insightful questions to ask the interviewer. This shows that you’re engaged and interested in the position and the company.

- “What are the current challenges and opportunities in the coremaking industry?”

- “How does the company invest in the professional development of its employees?”

4.Dress Professionally

First impressions matter, so dress professionally for the interview. Business attire will convey your respect for the interviewer and the company.

- Choose a suit or dress pants with a button-down shirt or blouse.

- Make sure your clothes are clean, pressed, and fit well.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Coremaking Machine Setter role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.