Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Corrugator Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

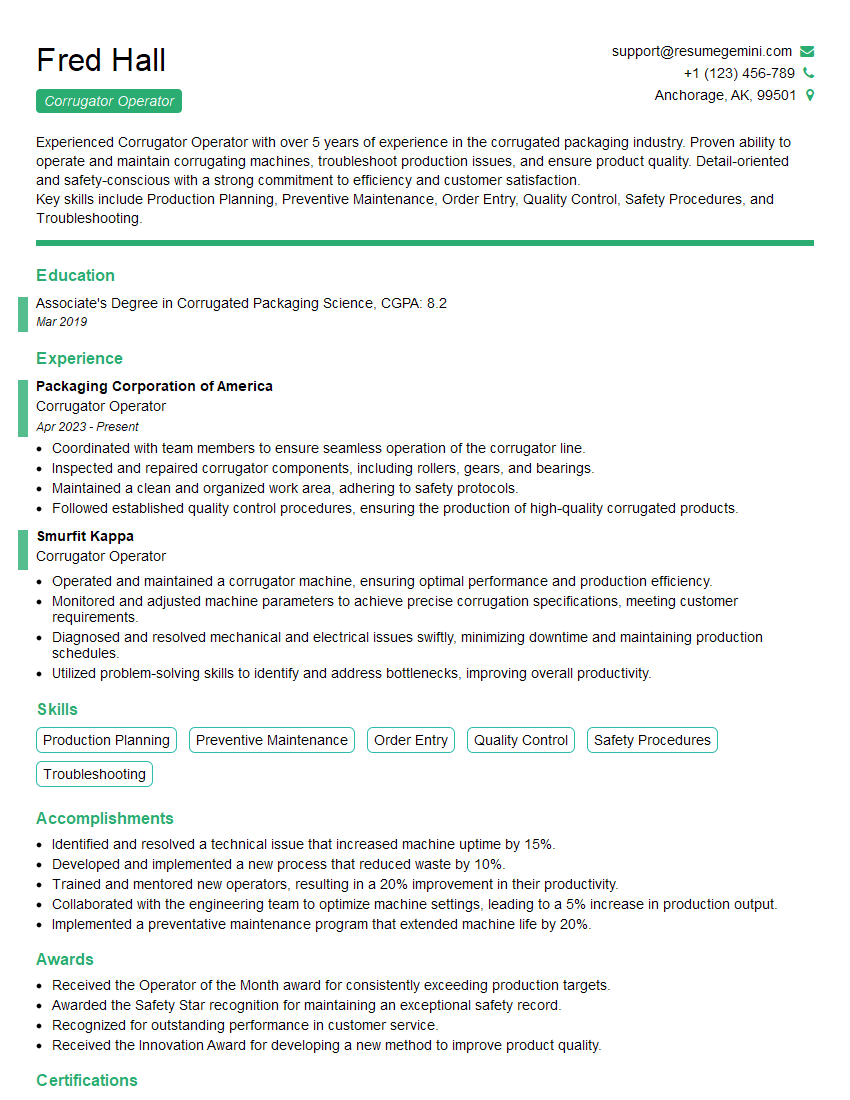

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Corrugator Operator

1. Describe the process of setting up and operating a corrugator machine?

In setting up a corrugator machine, I follow these key steps:

- Inspect the machine and ensure all components are in good working condition.

- Check the paper rolls, glue, and starch levels and make necessary adjustments.

- Configure the machine settings based on the order specifications, including flute type, paper thickness, and speed.

During operation, I monitor the machine’s performance closely:

- Observe the paper flow and make adjustments to maintain proper alignment.

- Control the speed and tension of the paper to ensure optimal bonding.

- Monitor glue and starch application to maintain the desired bond strength.

2. What safety precautions do you observe when working with a corrugator machine?

Personal Protective Equipment

- Wear appropriate safety gear, including gloves, eye protection, and earplugs.

- Maintain a clean and organized work area to prevent slips and falls.

Machine Operation

- Follow lockout/tagout procedures before performing maintenance or repairs.

- Never enter the machine while it’s in operation.

- Use caution when working with hot surfaces and moving parts.

Emergency Situations

- Be aware of emergency stop buttons and procedures.

- Know the location of fire extinguishers and other safety equipment.

3. How do you troubleshoot common problems that arise during the corrugating process?

I approach troubleshooting systematically:

- Identify the problem and its potential causes.

- Check the machine settings, paper quality, and glue/starch levels.

- Inspect the machine for any mechanical issues or blockages.

Here are some common issues and their solutions:

- Poor bonding: Adjust glue/starch levels or check for uneven paper flow.

- Paper tearing: Check tension settings, alignment, or the condition of the cutting blades.

- Flute crush: Adjust flute height or speed settings.

4. What maintenance tasks do you perform to ensure the corrugator machine operates efficiently?

I perform regular maintenance tasks to keep the machine in optimal condition:

- Daily: Clean and inspect the machine, lubricate moving parts, and check fluid levels.

- Weekly: Perform more thorough cleaning, inspect and replace worn parts, and calibrate sensors.

- Monthly: Conduct a comprehensive inspection, including belts, rollers, and bearings.

By adhering to a regular maintenance schedule, I minimize downtime and ensure the machine operates at peak performance.

5. How do you optimize the corrugator machine’s performance to maximize production output?

I employ several strategies to optimize performance and increase production output:

- Fine-tune settings: Adjust the machine’s speed, tension, and glue/starch levels to find the optimal balance for the desired output quality.

- Minimize downtime: Perform regular maintenance and troubleshoot promptly to minimize unplanned interruptions.

- Monitor machine performance: Track key metrics and identify areas for improvement, such as reducing waste or increasing speed.

6. Explain the process of splicing paper rolls on the corrugator machine?

To splice paper rolls efficiently, I follow these steps:

- Prepare the new roll by removing the outer layers and cutting a clean edge.

- Align the new roll with the running roll and overlap the edges.

- Apply glue or starch to the overlapping area and press them together firmly.

- Cut the excess paper from the overlap and check the splice for strength.

Proper splicing ensures continuous paper flow and minimizes downtime during production.

7. How do you handle and resolve customer complaints related to corrugated board quality?

When addressing customer complaints, I follow these steps:

- Listen actively: Understand the customer’s concerns and gather specific details about the issue.

- Investigate the issue: Inspect the affected product and analyze the production data to identify the potential cause.

- Communicate findings: Inform the customer about the investigation results and explain the steps taken to resolve the issue.

- Implement corrective actions: Adjust machine settings, modify production processes, or suggest alternative materials to address the problem.

By handling complaints professionally and effectively, I maintain customer satisfaction and build strong relationships.

8. Describe your experience with different types of paper and the challenges associated with corrugating each type?

I have experience working with a wide range of paper grades, each with its unique challenges:

- Kraft paper: Strong and durable, but requires careful handling to avoid tearing.

- Testliner: Smooth and inexpensive, but prone to moisture absorption.

- White top liner: Bright and printable, but more delicate and susceptible to damage.

To ensure optimal corrugation and product quality, I adjust the machine settings and handling techniques based on the paper type.

9. How do you stay up-to-date with the latest corrugating industry trends and advancements?

I make a conscious effort to stay informed about industry trends and advancements:

- Attend industry conferences and exhibitions: Network with peers and learn about new technologies and best practices.

- Read trade publications and online resources: Stay abreast of the latest industry news and research findings.

- Participate in training programs: Enhance my knowledge and skills through formal training opportunities.

By keeping up-to-date, I can continuously improve my performance and contribute to the advancement of the corrugating industry.

10. What strategies do you employ to reduce waste and improve sustainability in the corrugating process?

I prioritize waste reduction and sustainability through the following strategies:

- Optimize machine settings: Fine-tune settings to minimize paper waste and energy consumption.

- Recycle paper scraps: Collect and recycle paper waste to reduce environmental impact.

- Use eco-friendly materials: Explore biodegradable or recycled materials for packaging solutions.

By adopting sustainable practices, I contribute to reducing the environmental footprint of the corrugating process.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Corrugator Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Corrugator Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Corrugator Operator is responsible for operating and maintaining corrugating equipment to produce corrugated board products. They work in a fast-paced manufacturing environment and must be able to work well under pressure.

1. Operation of Corrugating Equipment

The Corrugator Operator is responsible for the safe and efficient operation of all corrugating equipment, including the corrugator, slitter, and stacker. They must be able to monitor the equipment closely and make adjustments as needed to ensure that the products meet specifications.

- Operate and maintain corrugating equipment

- Set up and adjust equipment to produce corrugated board

- Monitor equipment during operation and make adjustments as needed

- Troubleshoot and repair equipment problems

2. Product Quality Assurance

The Corrugator Operator is responsible for ensuring that the corrugated board products meet all quality standards. They must be able to inspect the products visually and identify any defects. They must also be able to take corrective action to prevent defects from occurring.

- Inspect corrugated board products for defects

- Identify and correct defects in corrugated board products

- Maintain quality control records

- Work with other departments to ensure that quality standards are met

3. Safety and Housekeeping

The Corrugator Operator is responsible for maintaining a safe and clean work environment. They must be able to follow all safety procedures and wear all required personal protective equipment. They must also be able to keep the work area clean and organized.

- Follow all safety procedures

- Wear all required personal protective equipment

- Keep the work area clean and organized

- Report any safety hazards

4. Training and Development

The Corrugator Operator is responsible for their own training and development. They must be willing to learn new skills and knowledge to stay current with the latest industry trends.

- Attend training programs

- Read industry publications

- Participate in online forums

- Network with other Corrugator Operators

Interview Tips

To ace the interview for a Corrugator Operator position, it is important to be prepared and to practice answering common interview questions. Here are a few tips to help you succeed:

1. Research the company and the position

Before you go to the interview, it is important to research the company and the position. This will help you to understand the company’s culture and its needs. It will also help you to answer questions about your qualifications and how you can contribute to the company.

- Visit the company’s website

- Read the job description

- Talk to people who work at the company

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked. It is helpful to practice answering these questions in advance so that you can feel confident and articulate during the interview.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What are your salary expectations?

3. Be prepared to talk about your experience

The interviewer will want to know about your experience as a Corrugator Operator. Be prepared to talk about your skills and knowledge, and be sure to highlight your accomplishments.

- Discuss your experience operating and maintaining corrugating equipment.

- Describe your experience inspecting and identifying defects in corrugated board products.

- Explain how you have maintained a safe and clean work environment.

4. Be professional and enthusiastic

It is important to be professional and enthusiastic during the interview. This will show the interviewer that you are serious about the position and that you are eager to work for the company.

- Dress appropriately.

- Be on time for the interview.

- Be polite and respectful to the interviewer.

- Be positive and enthusiastic about the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Corrugator Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!