Are you gearing up for an interview for a Die Caster position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Die Caster and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

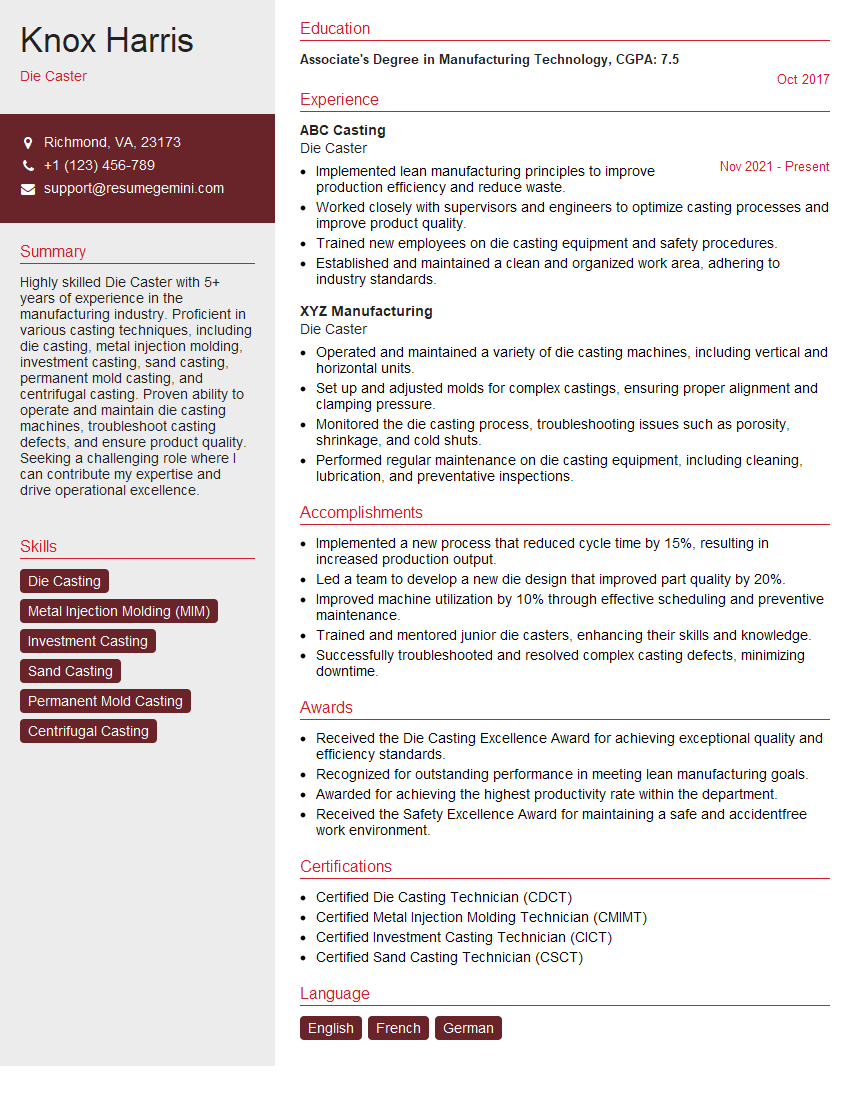

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Die Caster

1. Explain the process of die casting?

- Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity.

- The mold cavity is created using two hardened tool steel dies which have been machined to the desired shape of the casting.

- The molten metal is forced into the mold cavity under high pressure, typically using a hydraulic or pneumatic system.

- The metal solidifies rapidly within the mold cavity, and once it has solidified, the dies are opened and the casting is ejected.

2. What are the different types of die casting machines?

- There are two main types of die casting machines: hot-chamber machines and cold-chamber machines.

- Hot-chamber machines have a molten metal reservoir that is located inside the machine, and the metal is forced into the mold cavity using a plunger.

- Cold-chamber machines do not have a molten metal reservoir, and the molten metal is poured into the machine from a separate ladle.

3. What are the advantages and disadvantages of die casting?

Advantages

- Die casting can produce parts with complex shapes and high dimensional accuracy.

- Die casting can be used to produce parts with thin walls and intricate details.

- Die casting can produce parts with a high surface finish.

- Die casting is a relatively fast and efficient process.

Disadvantages

- Die casting can be expensive, especially for small production runs.

- Die casting can produce parts with porosity and other defects.

- Die casting can be limited by the size and complexity of the parts that can be produced.

4. What are the different types of materials that can be die cast?

- Die casting can be used to cast a wide variety of materials, including aluminum, zinc, magnesium, copper, and iron.

- The choice of material depends on the desired properties of the casting, such as strength, weight, and corrosion resistance.

5. What are the different factors that can affect the quality of a die casting?

- The quality of a die casting can be affected by a number of factors, including the design of the die, the type of material being cast, the casting process parameters, and the post-casting heat treatment.

- It is important to control these factors carefully in order to produce high-quality castings.

6. What are the different types of defects that can occur in die castings?

- Die castings can be subject to a number of different defects, including porosity, shrinkage, cold shuts, and cracks.

- It is important to be able to identify and correct these defects in order to produce high-quality castings.

7. What are the different types of post-casting heat treatments that can be used to improve the properties of die castings?

- Die castings can be subjected to a number of different post-casting heat treatments to improve their properties.

- These heat treatments can include annealing, tempering, and precipitation hardening.

8. What are the safety precautions that must be taken when working with die casting machines?

- Die casting machines can be hazardous, and it is important to take the following safety precautions when working with them.

- Wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Be aware of the location of the emergency stop button and how to use it.

- Never operate a die casting machine without being properly trained.

9. What is your experience with die casting?

- I have worked as a die caster for the past 5 years.

- I have experience with a variety of die casting machines and materials.

- I am familiar with the different types of defects that can occur in die castings and how to correct them.

10. Why do you want to work as a die caster?

- I am passionate about die casting and I enjoy the challenge of producing high-quality castings.

- I am also interested in learning more about the die casting process and how to improve my skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Die Caster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Die Caster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Die Casters are responsible for the operation and maintenance of die casting machines to produce metal parts and components. They ensure the quality of the castings and identify and resolve production issues.

1. Machine Operation

Operate die casting machines to inject molten metal into molds to produce castings.

- Set up and calibrate machine parameters according to job specifications.

- Monitor machine operation and adjust settings as needed to optimize production.

2. Quality Control

Inspect castings for defects and ensure they meet quality standards.

- Perform visual inspections and use measuring instruments to verify dimensions and tolerances.

- Identify and resolve casting defects such as porosity, cold shuts, and misruns.

3. Maintenance and Troubleshooting

Perform routine maintenance and troubleshooting on die casting machines.

- Lubricate and clean machines to ensure smooth operation.

- Identify and repair mechanical and electrical problems to minimize downtime.

4. Production Optimization

Monitor production processes and identify areas for improvement.

- Suggest changes to machine settings and operating procedures to increase efficiency.

- Collaborate with other departments to resolve production issues and optimize overall workflow.

Interview Tips

Preparing for a die caster interview requires a combination of technical knowledge, industry awareness, and effective communication skills.

1. Research the Role and Company

Thoroughly review the job description and company website to understand the specific requirements of the role and the organization’s culture.

- Identify key responsibilities and skills mentioned in the job description.

- Research the company’s products, services, and industry standing.

2. Highlight Relevant Experience

Emphasize your experience in die casting, including your knowledge of machine operation, quality control, and maintenance.

- Quantify your accomplishments using specific metrics and examples.

- Discuss any certifications or training programs you have completed.

3. Showcase Problem-Solving Abilities

Die casting often involves troubleshooting and problem-solving. Provide examples of how you have identified and resolved issues in previous roles.

- Describe a situation where you diagnosed a machine malfunction.

- Explain how you analyzed the root cause and implemented a solution.

4. Demonstrate Quality Consciousness

Emphasize your commitment to quality and your understanding of quality control procedures in die casting.

- Explain your approach to ensuring the accuracy and consistency of castings.

- Discuss your experience in using inspection equipment and verifying dimensions.

5. Practice Common Interview Questions

Prepare answers to common interview questions related to die casting, such as:

- “Tell me about your experience in operating die casting machines.”

- “How do you ensure the quality of die castings?”

- “Describe a time you troubleshoot a casting defect.”

Next Step:

Now that you’re armed with the knowledge of Die Caster interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Die Caster positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini