Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hot Molder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

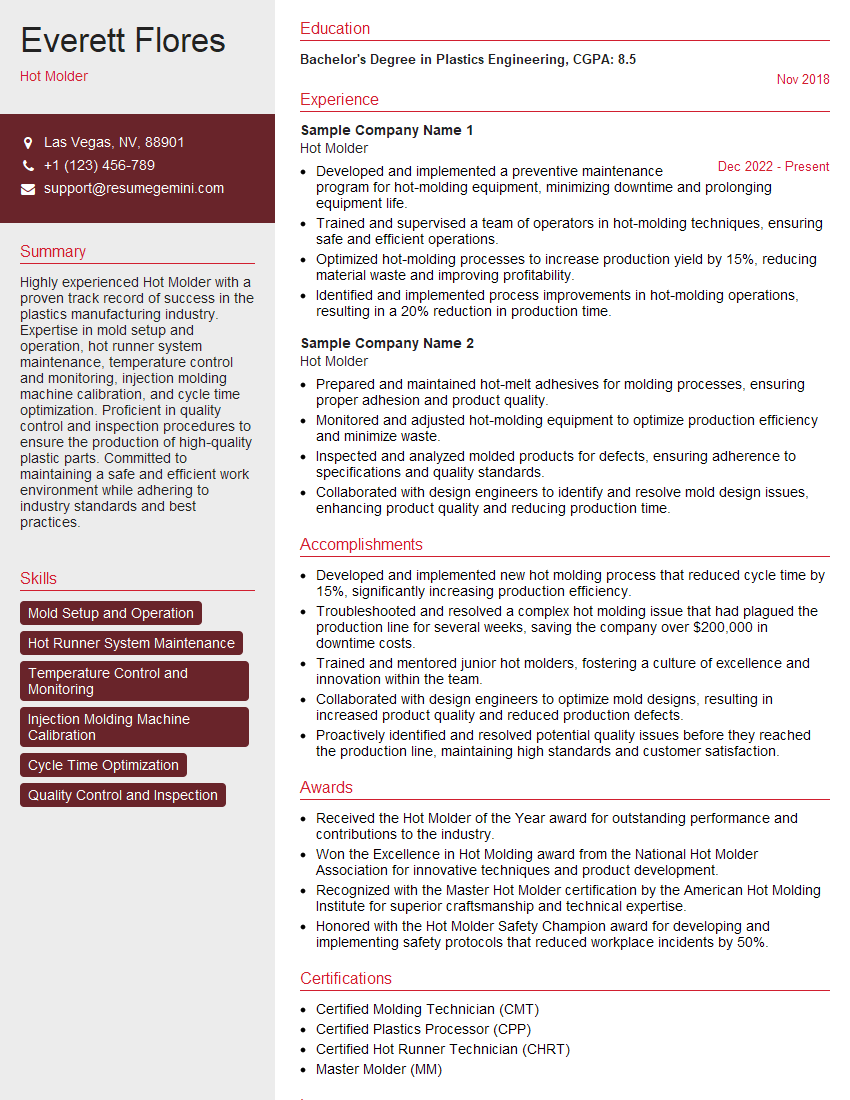

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hot Molder

1. What is the difference between a hot runner and a cold runner system?

- In a hot runner system, the plastic material is kept molten all the way through the injection mold, whereas in a cold runner system, the plastic material solidifies as it flows through the runner.

- Hot runner systems are more expensive to set up, but they can offer several advantages over cold runner systems, including reduced cycle times, less waste, and improved part quality.

2. What are the different types of hot runner systems?

Valve gate systems

- Valve gate systems use a valve to control the flow of plastic material into the mold cavity.

- Valve gate systems are capable of producing high-quality parts with minimal flash and waste.

Sprue gate systems

- Sprue gate systems use a sprue to form the connection between the runner and the mold cavity.

- Sprue gate systems are less expensive than valve gate systems, but they can produce more flash and waste.

Open gate systems

- Open gate systems do not use a valve or sprue to control the flow of plastic material into the mold cavity.

- Open gate systems are the least expensive type of hot runner system, but they can produce more flash and waste than valve gate or sprue gate systems.

3. What are the advantages of using a hot runner system?

- Reduced cycle times

- Less waste

- Improved part quality

- Reduced energy consumption

- Improved safety

4. What are the disadvantages of using a hot runner system?

- Higher initial cost

- More complex to operate and maintain

- Can be more difficult to troubleshoot

5. What are the key factors to consider when selecting a hot runner system?

- Type of plastic material being processed

- Part geometry

- Production volume

- Quality requirements

- Budget

6. What are the common problems that can occur with hot runner systems?

- Leakage

- Clogging

- Burnout

- Sticking

7. How do you troubleshoot a hot runner system?

- Check for leaks

- Check for clogs

- Check for burnout

- Check for sticking

8. What types of maintenance are required for a hot runner system?

- Regular cleaning

- Periodic inspection

- Replacement of worn or damaged parts

9. What are the safety precautions that must be taken when working with a hot runner system?

- Wear appropriate safety gear

- Be aware of the location of the hot runner

- Do not touch the hot runner

- Be aware of the potential for leaks and spills

10. What are the future trends in hot runner technology?

- Increased use of advanced materials

- Development of new and innovative designs

- Improved control systems

- Greater integration with other manufacturing technologies

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hot Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hot Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hot Molders play a pivotal role in the manufacturing process by operating and monitoring hot molding machines. They ensure that these machines produce high-quality products while adhering to safety protocols.

1. Machine Operation and Maintenance

Hot Molders are responsible for setting up, operating, and maintaining hot molding machines. They adjust machine settings, load raw materials, and monitor the molding process to ensure that products meet specifications.

- Set up and adjust molding machines according to product specifications.

- Monitor machine performance and make necessary adjustments to optimize production.

- Perform routine maintenance and troubleshoot minor machine issues.

2. Quality Control

Hot Molders inspect and evaluate molded products to ensure they meet quality standards. They identify and correct defects, maintaining product consistency and preventing customer dissatisfaction.

- Inspect molded products for defects such as cracks, warping, or dimensional inaccuracies.

- Identify and correct any defects by adjusting machine settings or replacing faulty molds.

- Maintain detailed records of quality checks and report any issues to supervisors.

3. Material Handling and Inventory Management

Hot Molders manage raw materials, finished products, and scrap materials. They ensure that materials are stored safely, accounted for, and used efficiently.

- Load and unload raw materials and finished products from molding machines.

- Maintain inventory records and track material usage.

- Dispose of scrap materials in accordance with environmental regulations.

4. Safety and Compliance

Hot Molders prioritize workplace safety and follow established safety guidelines. They wear protective gear, operate machines properly, and maintain a clean and organized work area.

- Wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Follow all safety procedures and report any potential hazards.

- Maintain a clean and organized work area to prevent accidents.

Interview Tips

Preparing thoroughly for an interview is crucial to making a positive impression and increasing your chances of success. Here are some tips to help you ace your Hot Molder interview:

1. Research the Company and Position

Familiarize yourself with the company’s background, products, and industry standing. Research the specific role and its responsibilities to demonstrate your interest and understanding.

- Visit the company website and LinkedIn page.

- Read industry news and articles to stay informed about the latest trends.

- Practice answering questions about your skills and how they align with the job requirements.

2. Highlight Your Technical Skills

Emphasize your technical expertise in operating hot molding machines. Discuss your experience with specific machines, materials, and molding techniques. Quantify your results whenever possible.

- Provide specific examples of how you have improved production efficiency or reduced defects.

- Mention any certifications or training programs you have completed to enhance your skills.

- Show your eagerness to learn new technologies and stay updated with industry advancements.

3. Demonstrate Quality Control Expertise

Showcase your understanding of quality control processes and your ability to identify and correct defects. Explain how you have maintained high-quality standards and met customer expectations.

- Describe your methods for inspecting and evaluating molded products.

- Explain how you identify and address the root causes of quality issues.

- Emphasize your attention to detail and your commitment to producing high-quality products.

4. Emphasize Safety and Compliance

Convey your strong commitment to safety and compliance. Discuss your knowledge of safety regulations and your experience in maintaining a safe and accident-free work environment.

- Explain your understanding of OSHA regulations and how you have implemented safety protocols.

- Describe your experience in hazard identification and risk assessment.

- Show your willingness to follow safety procedures and report any potential safety concerns.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Hot Molder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.