Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Label Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

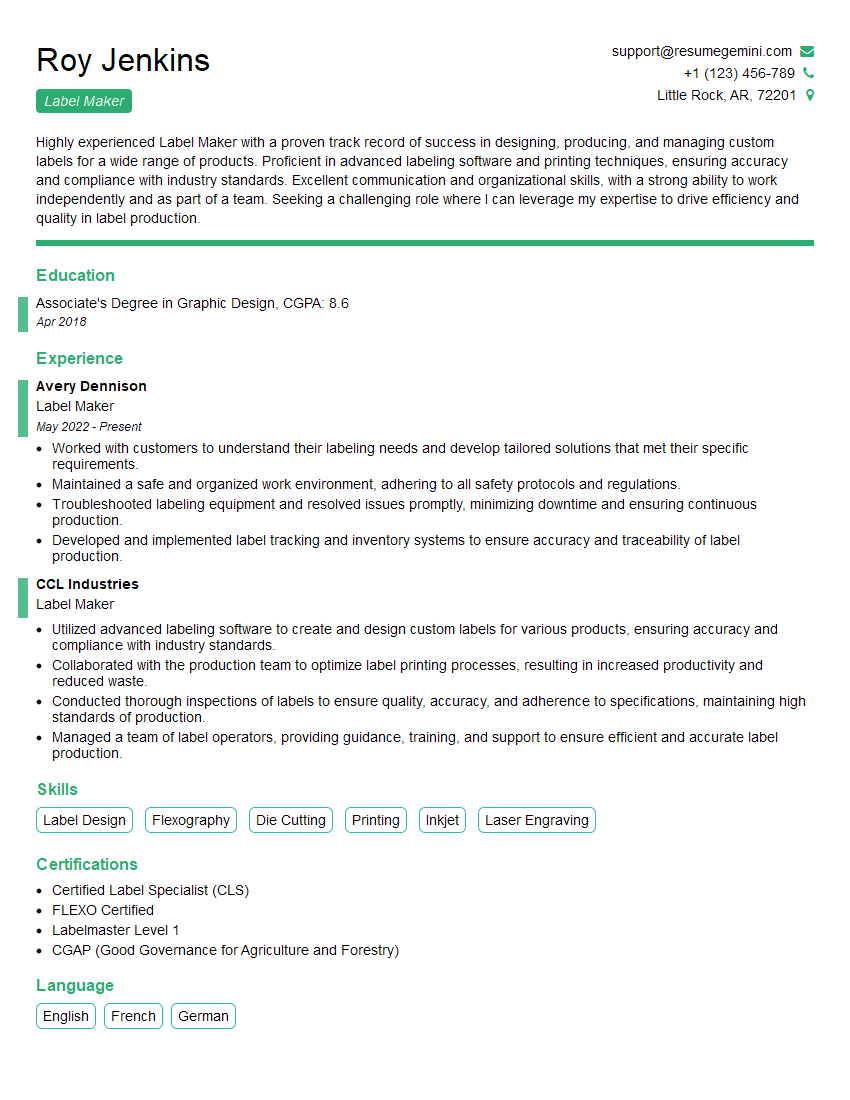

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Label Maker

1. Describe the process of creating a custom label design using a label maker.

The process of creating a custom label design using a label maker typically involves the following steps:

- Select a label template: Choose a pre-designed template or create a custom one using the label maker’s software.

- Add text and graphics: Input the desired text, images, or other graphics into the template.

- Format the design: Adjust the font, size, color, and alignment of the text and graphics.

- Preview and print: Review the design on the label maker’s screen before printing the labels.

2. What are the different types of materials that can be used with a label maker?

Types of Label Materials

- Paper: Standard paper labels are versatile and cost-effective.

- Plastic: Durable and water-resistant, ideal for outdoor or industrial use.

- Fabric: Washable and iron-on labels for clothing and other fabrics.

- Metal: Strong and durable labels suitable for heavy-duty applications.

- Vinyl: A versatile material with excellent weather resistance and adhesion.

3. How do you troubleshoot a label maker that is not printing correctly?

Troubleshooting a label maker that is not printing correctly involves the following steps:

- Check the power source: Ensure the label maker is properly plugged in and the batteries (if applicable) are fresh.

- Clear any jams: Open the label maker and carefully remove any jammed labels or debris.

- Clean the print head: Use a cotton swab and rubbing alcohol to gently clean the print head.

- Update the software: Download and install the latest software updates for the label maker.

- Contact customer support: If the issue persists, reach out to the manufacturer’s customer support for assistance.

4. Explain the difference between thermal transfer and direct thermal printing technologies used in label makers.

Thermal transfer printing uses a heated ribbon to transfer ink onto a label, while direct thermal printing uses heat to activate chemicals on the label material itself.

- Thermal Transfer:

- Produces high-quality, durable labels

- Uses a separate ink ribbon

- More expensive than direct thermal

- Direct Thermal:

- Less expensive and simpler to use

- Labels are not as durable as thermal transfer

- No separate ink ribbon required

5. What safety precautions should be taken when using a label maker?

- Keep away from children: Label makers may contain small parts or sharp edges.

- Use in a well-ventilated area: Some label makers emit fumes during printing.

- Follow the manufacturer’s instructions: Refer to the user manual for proper usage and maintenance.

- Dispose of labels properly: Do not flush labels down the toilet as they may clog pipes.

- Care for the print head: Clean the print head regularly to prevent smudging or poor print quality.

6. Describe the features and benefits of a high-volume label maker.

- High print speed: Produces labels quickly to meet high-volume demands.

- Large label capacity: Reduces the frequency of reloading labels.

- Automated label dispensing: Simplifies and speeds up the labeling process.

- Advanced software: Offers customization options and database integration.

- Durability: Designed to handle heavy-duty usage and produce long-lasting labels.

7. How do you ensure the accuracy of labels produced using a label maker?

- Proofread before printing: Carefully review the design for errors in text, graphics, or formatting.

- Use high-quality materials: Choose durable labels and inks to prevent fading or smudging.

- Calibrate the label maker: Follow the manufacturer’s instructions to ensure proper alignment and print quality.

- Test prints: Run a few test prints to verify the accuracy and quality of the labels before producing large quantities.

- Use a barcode scanner: For critical applications, use a barcode scanner to verify the accuracy of the printed barcodes.

8. What is the best way to store labels to ensure their longevity?

- Store in a cool, dry place: Avoid extreme temperatures and humidity.

- Keep away from direct sunlight: UV rays can damage the labels.

- Use resealable packaging: Protect labels from dust and moisture.

- Store rolls vertically: Prevent labels from bending or curling.

- Follow the manufacturer’s storage recommendations: Refer to the label packaging for specific storage instructions.

9. How do you handle customer inquiries or complaints related to label makers or labels?

- Listen attentively: Allow the customer to fully explain their issue.

- Troubleshoot the problem: Ask clarifying questions and try to identify the root cause.

- Offer solutions: Provide clear and effective solutions, such as troubleshooting steps or replacement products.

- Be empathetic and understanding: Show the customer that you value their concerns.

- Follow up: Check in with the customer to ensure the issue has been resolved.

10. What are the industry trends and advancements in label maker technology?

- Increased automation: Automated label dispensers and software integrations improve efficiency.

- Mobile printing: Portable label makers allow for printing on the go.

- RFID labels: Radio frequency identification labels enable advanced asset tracking and data collection.

- Cloud-based software: Connects label makers to remote databases and simplifies design collaboration.

- Sustainable materials: Eco-friendly label materials reduce environmental impact.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Label Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Label Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Label Makers are responsible for designing, creating, and producing high-quality labels for various products and applications. These professionals work closely with clients to understand their specific requirements and develop customized label solutions that meet their needs. Key job responsibilities include:

1. Label Design and Development

Collaborating with clients to determine label specifications, including size, shape, material, and design. Designing and creating visually appealing and informative labels that meet brand guidelines and marketing objectives. Ensuring label designs are optimized for readability, impact, and compliance with industry standards.

2. Label Production

Setting up and operating printing equipment to produce labels efficiently and accurately. Monitoring the production process to ensure high-quality standards and timely delivery. Managing inventory of label materials and supplies.

3. Quality Assurance

Conducting thorough inspections of labels to verify accuracy, clarity, and durability. Identifying and resolving any production issues promptly. Maintaining records of label production and quality control.

4. Customer Service

Providing excellent customer service by responding promptly to inquiries and resolving concerns effectively. Building and maintaining strong relationships with clients.

Interview Tips

Preparing for a Label Maker interview requires a combination of technical knowledge, industry understanding, and interpersonal skills. Here are some tips to help candidates ace the interview:

1. Research the Company and Position

Take the time to thoroughly research the company you’re applying to, including its products, services, and industry reputation. Understand the specific requirements of the Label Maker position and how your skills and experience align with the role.

2. Practice Your Technical Skills

Be prepared to demonstrate your label design and production capabilities. Create a portfolio of your previous work, highlighting your skills in creating visually appealing and functional labels. If possible, bring a sample of your work to the interview.

3. Highlight Your Quality Assurance Expertise

Emphasize your commitment to producing high-quality labels. Discuss your experience in conducting thorough inspections and implementing quality control measures. Provide specific examples of how you have identified and resolved production issues.

4. Showcase Your Customer Service Skills

Label Makers interact with clients regularly. Highlight your ability to provide excellent customer service by building rapport, responding promptly to inquiries, and resolving concerns effectively. Share examples of how you have gone above and beyond to meet client expectations.

5. Be Enthusiastic and Professional

Demonstrate your enthusiasm for the label-making industry and your passion for creating high-quality products. Dress professionally and arrive on time for your interview. Be prepared to ask thoughtful questions about the company and the position.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Label Maker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.