Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Injection Molding Process Technician position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

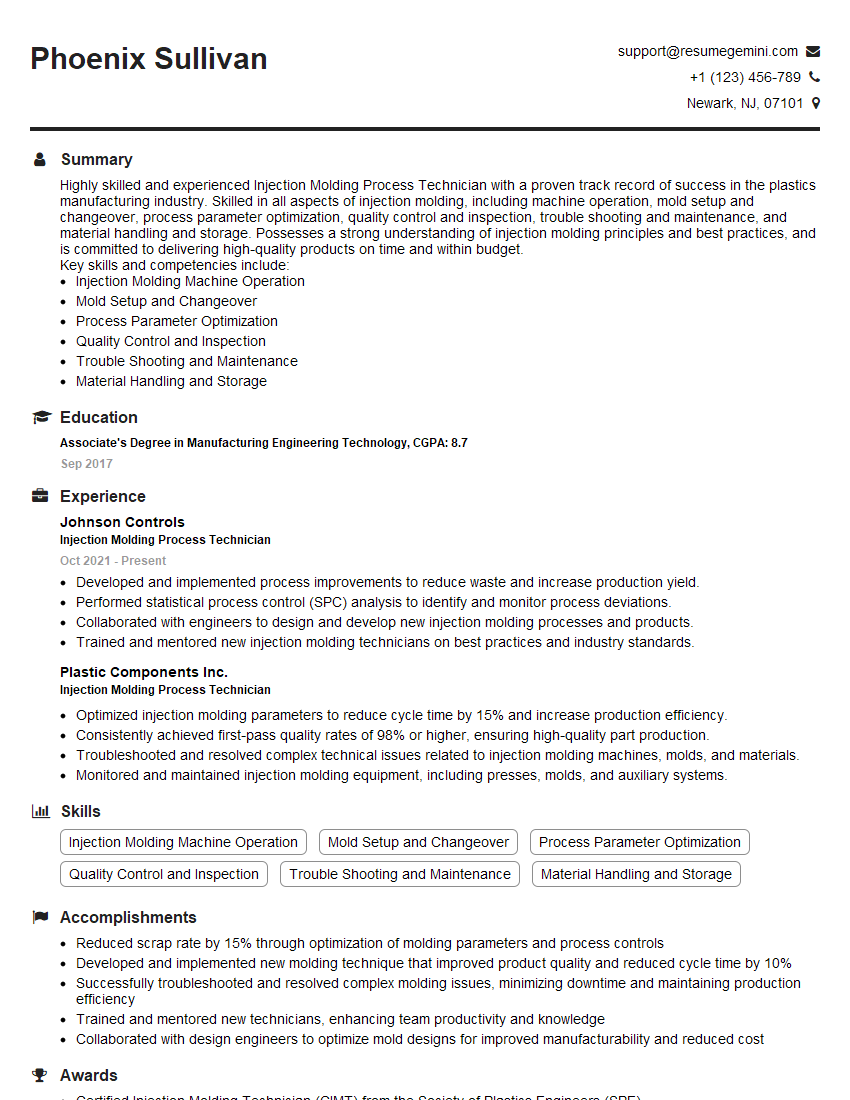

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Injection Molding Process Technician

1. How do you plan and prepare for an injection molding production run?

Prior to a production run, I follow these steps:

- Review production order and product specifications

- Gather necessary materials and tools

- Inspect mold and make any necessary adjustments

- Set up and calibrate injection molding machine

- Conduct trial runs to optimize process parameters

2. Describe the process of injection molding, including the different stages involved.

Material Preparation and Feeding

- Selecting and preparing the plastic material

- Feeding the material into the injection molding machine

Molding

- Clamping and sealing the mold

- Injecting the molten plastic material into the mold cavity

- Cooling and solidifying the plastic material in the mold

Ejection

- Opening the mold

- Ejecting the molded part from the mold

3. What are the common quality defects that can occur during injection molding and how do you prevent them?

Common quality defects and preventive measures include:

- Short shots (Incomplete filling): Optimize process parameters and maintain mold temperature

- Flash (Excess material): Adjust mold clamping force and check for mold wear

- Sink marks (Depressions): Increase injection pressure or packing time

- Warping (Dimensional distortion): Control cooling rate and mold temperature

- Voids (Air pockets): Degas the material, adjust injection pressure

4. How do you maintain and troubleshoot injection molding machines?

Regular maintenance and troubleshooting steps include:

- Cleaning and lubricating moving parts

- Checking hydraulic and electrical systems

- Identifying and resolving alarm codes

- Calibrating sensors and gauges

- Performing preventive maintenance as per manufacturer’s recommendations

5. What are the safety precautions to be observed when operating injection molding machines?

- Wear appropriate safety gear (gloves, safety glasses, etc.)

- Maintain a clean and well-organized work area

- Never reach into the mold area while the machine is in operation

- Follow lock-out/tag-out procedures during maintenance

- Be aware of potential hazards such as hot surfaces and moving parts

6. How do you improve the efficiency and productivity of an injection molding process?

- Optimize process parameters (injection pressure, temperature, etc.)

- Use high-quality molds and materials

- Implement automation to reduce cycle time

- Monitor and control machine performance

- Train operators on best practices

7. What types of plastic materials are used in injection molding and how do their properties affect the manufacturing process?

Common plastic materials include:

- Polyethylene (PE): Flexible, strong, low density

- Polypropylene (PP): Lightweight, impact-resistant, good chemical resistance

- Polystyrene (PS): Rigid, lightweight, cost-effective

- Acrylonitrile Butadiene Styrene (ABS): Strong, impact-resistant, good surface finish

- Polycarbonate (PC): High strength, clarity, heat resistance

8. How do you ensure the quality of injection molded parts?

- Inspect parts visually for defects

- Use measuring tools to check dimensions

- Perform mechanical tests to assess strength and durability

- Implement quality control procedures throughout the manufacturing process

- Monitor and record production data for continuous improvement

9. Describe your experience in working with different types of injection molding machines.

I have experience with various types of injection molding machines, including:

- Vertical and horizontal machines

- Hydraulic, electric, and hybrid machines

- Machines with different clamping forces and injection capacities

- I am proficient in operating and maintaining these machines efficiently.

10. What are your strengths and weaknesses as an Injection Molding Process Technician?

Strengths:

- Strong technical knowledge and experience in injection molding

- Excellent troubleshooting and problem-solving skills

- Attention to detail and commitment to quality

- Ability to work independently and as part of a team

Weaknesses:

- Still developing my expertise in working with certain specialized materials

- I am always eager to learn and improve my skills, so I am confident in my ability to overcome this weakness quickly.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Injection Molding Process Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Injection Molding Process Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Injection Molding Process Technicians are responsible for operating, maintaining, and troubleshooting injection molding machines used to produce plastic parts. They ensure that the machines are running smoothly and efficiently, and that the parts meet the required quality standards.

1. Operate Injection Molding Machines

Injection Molding Process Technicians are responsible for operating injection molding machines. This involves:

- Loading the machine with raw materials

- Setting up the machine according to the product specifications

- Monitoring the machine during the molding process

- Making adjustments to the machine to ensure that the parts meet the required quality standards

2. Maintain Injection Molding Machines

Injection Molding Process Technicians are also responsible for maintaining injection molding machines. This involves:

- Cleaning and lubricating the machine

- Inspecting the machine for wear and tear

- Replacing worn parts

- Troubleshooting and repairing the machine when necessary

3. Troubleshoot Injection Molding Problems

Injection Molding Process Technicians are also responsible for troubleshooting injection molding problems. This involves:

- Identifying the source of the problem

- Taking corrective action to solve the problem

- Preventing the problem from recurring

4. Quality Control

Injection Molding Process Technicians are also responsible for quality control. This involves:

- Inspecting the finished parts to ensure that they meet the required quality standards

- Taking corrective action if any defects are found

Interview Tips

To ace your interview for an Injection Molding Process Technician position, follow these tips:

1. Research the company and the position

Take some time to learn about the company you’re applying to, as well as the specific position you’re interested in. This will help you understand the company’s culture and values, as well as the specific skills and experience required for the job.

- Visit the company’s website

- Read industry articles and news about the company

- Look at the company’s social media pages

2. Practice your answers to common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?” Practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Use the STAR method to answer behavioral questions

- Prepare examples that highlight your skills and experience

- Practice your answers with a friend or family member

3. Be prepared to talk about your experience

The interviewer will want to know about your experience in operating and maintaining injection molding machines. Be prepared to discuss your experience in detail, including the types of machines you’ve worked on, the materials you’ve used, and the quality standards you’ve met.

- Quantify your accomplishments whenever possible

- Use specific examples to illustrate your skills

- Highlight your knowledge of the industry

4. Be confident and enthusiastic

The interviewer will be looking for someone who is confident and enthusiastic about the position. Show the interviewer that you’re excited about the opportunity to work for the company and that you’re confident in your abilities to do the job.

- Make eye contact with the interviewer

- Speak clearly and confidently

- Be positive and enthusiastic about the position

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Injection Molding Process Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!