Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Injection Molding Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

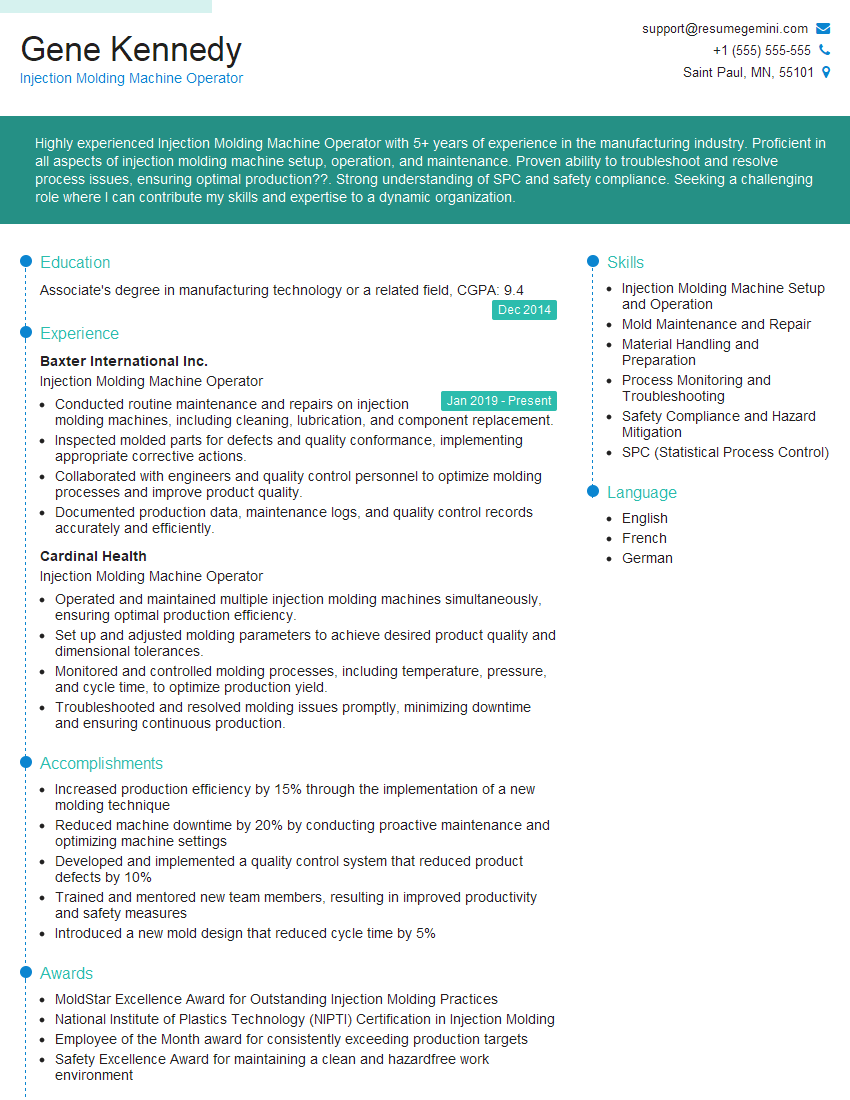

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Injection Molding Machine Operator

1. What are the key responsibilities of an Injection Molding Machine Operator?

As an Injection Molding Machine Operator, my primary responsibilities include:

- Setting up, operating, and maintaining injection molding machines to produce high-quality plastic parts.

- Monitoring machine parameters, such as temperature, pressure, and cycle time, to ensure optimal performance.

- Inspecting molded parts for defects and taking corrective actions as needed.

- Troubleshooting and resolving any technical issues that may arise during the molding process.

- Maintaining a clean and organized work area, adhering to safety protocols, and following standard operating procedures.

2. Describe the different types of injection molding machines and their applications?

There are several types of injection molding machines, each suited for different applications:

Vertical Injection Molding Machines:

- Clamping unit is vertical, allowing for easy part removal.

- Suitable for producing small to medium-sized parts with complex geometries.

Horizontal Injection Molding Machines:

- Clamping unit is horizontal, providing more space for mold and part handling.

- Used for producing large and heavy parts.

Rotary Injection Molding Machines:

- Features a rotating platen that allows for continuous production.

- Ideal for producing high-volume, simple parts.

3. Explain the injection molding process and the key parameters that affect part quality?

The injection molding process involves the following steps:

- Plastic pellets are melted in the injection unit.

- Melted plastic is injected into a mold cavity under high pressure.

- Plastic cools and solidifies within the mold.

- Mold opens, and the finished part is ejected.

Critical parameters affecting part quality include:

- Mold temperature and cooling time

- Injection pressure and speed

- Material properties and melt temperature

- Mold design and gate location

4. How do you troubleshoot common injection molding defects such as warpage, sink marks, and short shots?

Troubleshooting injection molding defects requires:

- Identifying the defect type and its potential causes.

- Inspecting the mold and machine settings for issues.

- Adjusting process parameters, such as temperature, pressure, or cycle time.

For example:

- Warpage: Can be caused by uneven cooling, mold misalignment, or excessive injection pressure.

- Sink marks: Result from material shrinkage during cooling, and can be addressed by increasing packing pressure or adding ribs to the part design.

- Short shots: Occur when insufficient material is injected into the mold, and can be resolved by increasing injection pressure or speed.

5. What are the different types of plastic materials used in injection molding, and how do their properties affect part design?

Common plastic materials used in injection molding include:

- Polyethylene (PE): Flexible, low-cost material, suitable for packaging and disposable products.

- Polypropylene (PP): Tough, lightweight material, used in automotive parts and appliances.

- Polystyrene (PS): Rigid, brittle material, used in disposable cups and food containers.

- Polyamide (PA): Strong, heat-resistant material, used in engineering applications.

- Polycarbonate (PC): Transparent, impact-resistant material, used in automotive parts and electronics.

Understanding the material properties is crucial for part design, as they influence factors such as strength, flexibility, heat resistance, and chemical resistance.

6. What maintenance procedures are essential for ensuring the optimal performance of injection molding machines?

Regular maintenance is critical for injection molding machines to operate efficiently and produce high-quality parts:

- Daily: Checking fluid levels, cleaning nozzles, and inspecting molds for wear.

- Weekly: Lubricating moving parts, replacing filters, and calibrating sensors.

- Monthly: Performing a thorough inspection of the machine, including electrical and mechanical components.

- Quarterly: Scheduling major overhauls, such as cleaning the hydraulic system or replacing worn parts.

7. How do you ensure safety in an injection molding environment?

Safety in injection molding is paramount:

- Wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and earplugs.

- Following lockout/tagout procedures when performing maintenance.

- Maintaining a clean and organized work area, free from tripping hazards or spills.

- Being aware of the location of emergency stop buttons and evacuation routes.

- Receiving proper training on machine operation and safety protocols.

8. Describe your experience in working with different mold designs and materials.

Throughout my career, I have worked with a variety of mold designs and materials, including:

- Two-plate molds: Simple and cost-effective for small parts.

- Three-plate molds: Allow for more complex part geometries and side actions.

- Hot runner molds: Eliminate the need for sprues and runners, reducing material waste.

- Overmolding molds: Used to combine different materials or colors into a single part.

I am familiar with mold materials such as steel, aluminum, and beryllium copper, each with its unique properties and applications.

9. How do you handle rejected parts and ensure quality control?

Handling rejected parts and maintaining quality control is crucial:

- Identifying defects: Inspecting parts visually and using measuring tools to identify any deviations from specifications.

- Segregating rejected parts: Keeping defective parts separate to prevent them from entering the finished goods inventory.

- Analyzing defects: Determining the root cause of the defects to implement corrective actions.

- Documenting rejects: Recording rejected parts, their defects, and the corrective measures taken.

- Continuous improvement: Monitoring reject rates and implementing quality improvement initiatives to reduce defects.

10. In a fast-paced production environment, how do you manage multiple machines and prioritize tasks effectively?

In a busy production environment, managing multiple machines and prioritizing tasks effectively is essential:

- Planning and scheduling: Creating a production schedule that optimizes machine utilization and minimizes downtime.

- Monitoring machine status: Regularly checking machine performance, identifying potential issues, and taking prompt action.

- Prioritizing tasks: Assessing the urgency and importance of tasks, focusing on critical jobs first.

- Multitasking: Being able to handle multiple tasks simultaneously, while maintaining accuracy and attention to detail.

- Communicating effectively: Coordinating with team members, supervisors, and maintenance personnel to ensure smooth production flow.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Injection Molding Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Injection Molding Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As an Injection Molding Machine Operator, your primary goal is to operate and maintain injection molding machinery to produce plastic parts. Your responsibilities can be categorized into four key areas:

1. Machine Operation

You will be responsible for setting up, operating, and monitoring injection molding machines to produce plastic parts. This will involve:

- Loading raw materials into the machine

- Setting up and adjusting machine parameters

- Monitoring the machine cycle

- Unloading finished parts

2. Machine Maintenance

You will also be responsible for maintaining and inspecting injection molding machines to minimize downtime and ensure optimal performance. This will involve:

- Performing routine maintenance tasks

- Troubleshooting machine problems

- Repairing and replacing machine parts

3. Quality Control

You will be responsible for inspecting finished parts to ensure they meet quality standards. This will involve:

- Checking parts for defects

- Measuring parts to ensure they meet specifications

- Rejecting defective parts

4. Safety

As an Injection Molding Machine Operator, you will be required to adhere to strict safety guidelines. This will involve:

- Wearing appropriate safety gear

- Following lockout/tagout procedures

- Maintaining a clean and organized work area

Interview Tips

To ace your interview for an Injection Molding Machine Operator position, it’s crucial to prepare thoroughly. Here are some tips to help you impress the interviewer:

1. Research the Company and the Position

Before the interview, take the time to learn about the company you’re applying to and the specific position you’re interested in. This will demonstrate your interest in the opportunity and show the interviewer that you’re serious about the job.

2. Practice Your Answers to Common Interview Questions

Some common interview questions for Injection Molding Machine Operators include:

- Tell me about your experience operating injection molding machines.

- What are your strengths and weaknesses as an Injection Molding Machine Operator?

- How do you handle machine breakdowns?

- What is your experience with quality control?

- Why are you interested in this position?

Take some time to think about your answers to these questions and practice delivering them clearly and confidently.

3. Be Prepared to Talk About Your Safety Experience and Knowledge

As an Injection Molding Machine Operator, safety is paramount. In the interview, you should be prepared to discuss your safety experience and knowledge. This could include:

- Your experience with lockout/tagout procedures

- Your knowledge of proper safety gear

- Your experience with maintaining a clean and organized work area

4. Ask the Interviewer Questions

At the end of the interview, the interviewer will likely ask if you have any questions. This is your opportunity to learn more about the company, the position, and the interviewer. Here are some questions you might consider asking

- What are the company’s goals for this position?

- What are the biggest challenges facing the company?

- What can you tell me about the company’s culture?

- What’s the next step in the interview process?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Injection Molding Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!