Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Machine Coremaker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

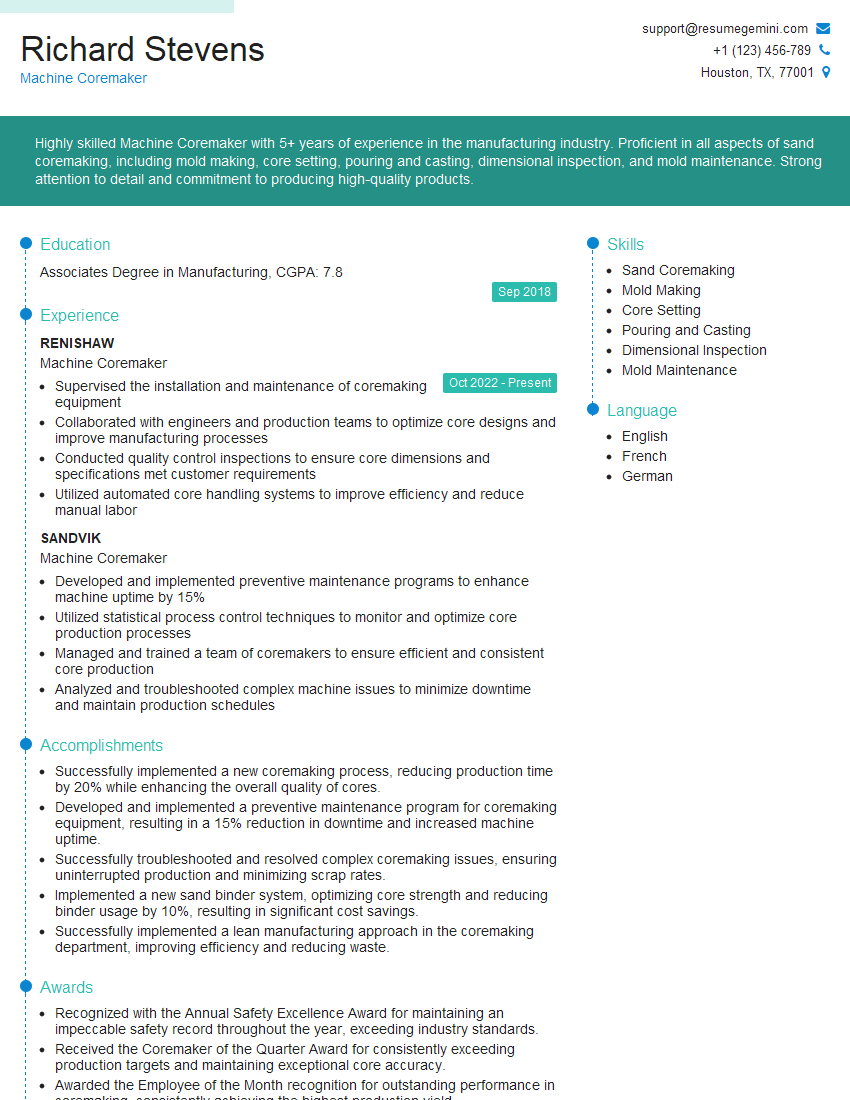

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Coremaker

1. Describe the process of preparing core boxes for core making.

- Clean the core box thoroughly to remove any dirt, debris, or old cores.

- Apply a release agent to the core box to prevent the core from sticking.

- Position the core box on the core making machine.

- Secure the core box in place using clamps or other fasteners.

2. Explain the different types of core making processes.

There are two main types of core making processes: manual and automated.

Manual core making processes

- Bench molding: This is the most basic type of core making process, and it involves hand-packing sand into a core box.

- Floor molding: This process is similar to bench molding, but it is done on a larger scale, and the core is made on the floor.

- Sweep molding: This process is used to make large, cylindrical cores. A sweep arm is used to shape the sand around a central axis.

Automated core making processes

- Blower core making: This process uses a blower to force sand into a core box.

- Shoot core making: This process uses a compressed air gun to shoot sand into a core box.

- Gas core making: This process uses a gas to create a void in the sand, which forms the core.

3. What are the different types of core binders and their applications?

- Organic binders: These binders are made from plant or animal materials, and they are typically used for cores that are not subjected to high temperatures.

- Inorganic binders: These binders are made from minerals, and they are typically used for cores that are subjected to high temperatures.

- Chemical binders: These binders are made from chemicals, and they are typically used for cores that require high strength or precision.

4. How do you control the quality of cores?

- Use high-quality materials.

- Follow the core making process carefully.

- Inspect the cores before they are used.

- Test the cores to ensure that they meet the required specifications.

5. What are the safety precautions that must be taken when operating core making machines?

- Wear appropriate safety gear, including gloves, safety glasses, and a dust mask.

- Operate the machine in a well-ventilated area.

- Follow the machine manufacturer’s instructions.

- Never put your hands or any other body parts into the machine while it is operating.

6. What are the common problems that can occur during core making and how do you troubleshoot them?

- Sticking cores: This can be caused by a number of factors, including the use of the wrong release agent, the core box being too wet, or the core being packed too tightly.

- Cracked cores: This can be caused by a number of factors, including the use of the wrong binder, the core being dried too quickly, or the core being subjected to excessive stress.

- Misshapen cores: This can be caused by a number of factors, including the use of the wrong core box, the core being packed unevenly, or the core being dried unevenly.

7. What is your experience with core making equipment?

I have experience with a variety of core making equipment, including bench molding machines, floor molding machines, sweep molding machines, blower core making machines, shoot core making machines, and gas core making machines.

8. What are your strengths and weaknesses as a core maker?

My strengths as a core maker include my attention to detail, my ability to follow instructions, and my ability to work independently. My weakness is that I am relatively new to the industry, and I do not have a lot of experience with some of the more advanced core making techniques.

9. Why do you want to work as a core maker?

I am interested in working as a core maker because I enjoy working with my hands, and I am fascinated by the process of creating metal castings. I believe that I have the skills and the motivation to be a successful core maker.

10. What are your salary expectations?

My salary expectations are in line with the industry average for core makers with my level of experience. I am willing to negotiate salary based on the benefits package and the company’s culture.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Coremaker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Coremaker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Coremakers are responsible for operating and maintaining coremaking machines that produce sand cores used in metal casting. The key job responsibilities include:

1. Machine Operation and Maintenance

Operate and maintain coremaking machines, ensuring they are in good working order and producing high-quality cores.

- Setting up and adjusting machine parameters to meet core specifications.

- Monitoring machine operation and troubleshooting any issues.

- Cleaning and maintaining machines to ensure optimal performance.

2. Core Production

Produce sand cores using various coremaking processes.

- Preparing sand mixtures according to specifications.

- Creating cores using core boxes or other forming methods.

- Inspecting cores to ensure they meet quality standards.

3. Quality Control

Maintain high-quality standards throughout the coremaking process.

- Monitoring core dimensions and properties to ensure they meet specifications.

- Inspecting cores for defects and taking corrective actions.

- Testing cores to ensure they meet performance requirements.

4. Safety and Compliance

Follow safety protocols and comply with industry regulations.

- Wearing appropriate personal protective equipment (PPE).

- Operating machines safely and following established procedures.

- Maintaining a clean and organized work area.

Interview Tips

To ace an interview for a Machine Coremaker position, candidates should consider the following tips:

1. Preparation

Research the company and the specific role to understand its requirements.

- Review the job description and identify the key skills and experience needed.

- Practice answering common interview questions related to machine operation, core production, and quality control.

2. Highlight Experience and Skills

Emphasize relevant experience and skills in your answers.

- Quantify accomplishments and provide specific examples of successful coremaking projects.

- Showcase expertise in machine operation, core production techniques, and quality control methods.

3. Demonstrate Safety Consciousness

Highlight your commitment to safety and compliance.

- Explain your understanding of industry regulations and safety protocols.

- Provide examples of how you have maintained a safe work environment.

4. Show Interest and Enthusiasm

Convey your enthusiasm for the role and the industry.

- Ask informed questions about the company, the position, and the coremaking process.

- Express your interest in learning new techniques and contributing to the team.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Machine Coremaker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!