Are you gearing up for an interview for a Metal Molder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Metal Molder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

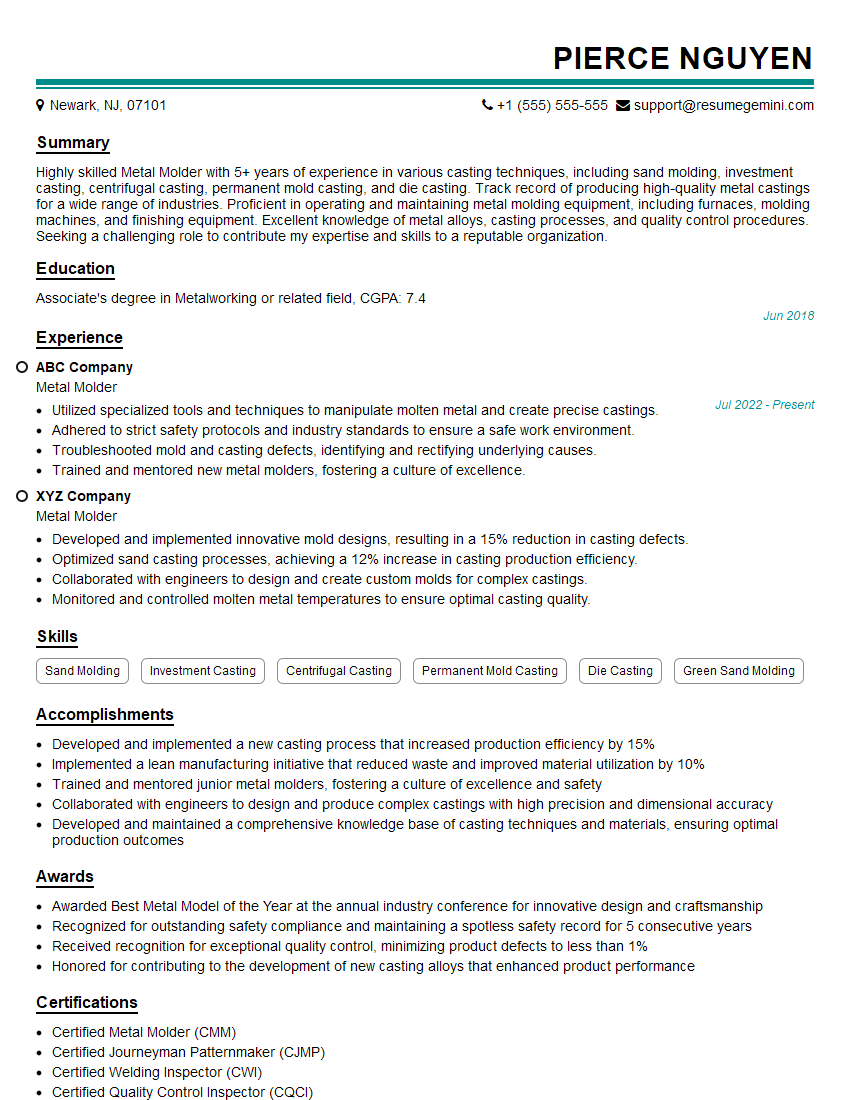

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Molder

1. Define the primary functions of a Metal Molder?

The primary functions of a Metal Molder include:

- Reading and interpreting blueprints and technical drawings

- Setting up and operating molding machines

- Preparing and pouring molten metal into molds

- Inspecting and finishing castings

- Maintaining and repairing molding equipment

2. Describe the different types of metal casting processes and their respective advantages and disadvantages?

Sand Casting:

- Advantages:

- Versatile and can produce complex shapes

- Low tooling costs

- Disadvantages:

- Less dimensional accuracy compared to other processes

- Surface finish may require additional machining

Investment Casting:

- Advantages:

- Produces high-precision castings with excellent surface finish

- Suitable for intricate shapes and small parts

- Disadvantages:

- Higher tooling costs

- Limited to smaller part sizes

Die Casting:

- Advantages:

- High production rates

- Excellent dimensional accuracy and repeatability

- Disadvantages:

- High tooling costs

- Not suitable for all metal types

3. Explain the factors that influence the selection of a specific casting process for a given application?

The selection of a casting process depends on various factors, including:

- Part Complexity: Some processes are better suited for complex geometries.

- Material Properties: Different metals and alloys have different casting characteristics.

- Production Volume: High-volume production may require automated processes like die casting.

- Dimensional Tolerances: Precision casting processes like investment casting are used for critical dimensions.

- Cost Constraints: Sand casting has lower tooling costs, while investment casting is more expensive.

4. Discuss the key considerations for designing and creating a metal mold?

When designing and creating a metal mold, key considerations include:

- Mold Material: Choosing the appropriate material for the mold based on molten metal’s temperature and properties.

- Mold Cavity Design: Designing the cavity to accommodate the part geometry, including draft angles and gating systems.

- Cooling System: Incorporating cooling channels or fins to regulate temperature and prevent heat buildup.

- Ejection Mechanism: Designing an effective ejection system to remove the casting from the mold.

- Mold Maintenance: Considering factors like mold wear and cleaning during the production process.

5. Explain the importance of gating and risering systems in metal casting?

Gating and risering systems are crucial in metal casting:

- Gating System:

- Controls the flow of molten metal into the mold cavity.

- Prevents defects such as cold shuts, short fills, and inclusions.

- Riser System:

- Compensates for metal shrinkage during solidification.

- Prevents voids or porosity in the casting.

6. Describe the different techniques used for inspecting metal castings?

Metal castings are inspected using various techniques, including:

- Visual Inspection: Checking for surface defects, such as cracks, porosity, and inclusions.

- Dimensional Inspection: Measuring the dimensions and tolerances of the casting.

- Radiography (X-ray or Gamma-ray): Detecting internal defects, such as voids and cracks.

- Ultrasonic Testing: Using sound waves to find internal discontinuities.

- Magnetic Particle Inspection: Locating surface and near-surface cracks.

7. How do you ensure the safety and quality of metal casting operations?

To ensure safety and quality in metal casting:

- Safety Protocols: Adhering to established safety procedures, wearing appropriate protective gear, and maintaining a safe work environment.

- Quality Control: Implementing quality checks throughout the process, from mold design to casting inspection.

- Preventive Maintenance: Regularly inspecting and maintaining equipment to minimize breakdowns and ensure consistent quality.

- Continuous Improvement: Identifying areas for improvement and implementing process enhancements to optimize production and quality.

8. Describe the importance of understanding metal properties and metallurgy in metal casting?

Understanding metal properties and metallurgy is essential in metal casting because:

- Material Selection: Knowing the properties of different metals and alloys helps in selecting the right material for the desired application.

- Casting Process Optimization: Adjusting casting parameters based on material characteristics, such as solidification rates and shrinkage, optimizes the process.

- Defect Prevention: Understanding metal behavior during casting allows for proactive measures to prevent defects like porosity and hot tears.

9. How do you stay updated with advancements in metal casting technologies and best practices?

To stay updated with metal casting advancements:

- Industry Publications: Regularly reading trade magazines and journals to gain knowledge on new technologies and techniques.

- Conferences and Webinars: Attending industry events to connect with professionals and learn about cutting-edge practices.

- Online Resources: Utilizing online platforms, such as technical forums and research papers, to access the latest information.

10. Describe a challenging or complex metal casting project you have worked on and how you overcame the challenges faced?

In a previous role, I was involved in a project to produce a high-volume, precision casting for a critical automotive component. The challenge lay in achieving the required dimensional tolerances while maintaining a high production rate. By optimizing the gating system, implementing a phased cooling process, and closely monitoring the casting parameters, we successfully met the specifications and delivered a high-quality product.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Metal Molders are responsible for creating metal castings by pouring molten metal into molds. They work in foundries and use a variety of tools and equipment to complete their tasks.

1. Prepare Molds

Metal Molders prepare the molds for casting by cleaning them and applying a mold release agent. They may also need to repair or alter molds as needed.

- Clean and inspect molds for damage

- Apply mold release agent to prevent sticking

- Repair or alter molds as needed

2. Melt Metal

Metal Molders melt metal in furnaces and ladles. They must carefully control the temperature of the molten metal to ensure that it is poured at the correct temperature.

- Load metal into furnaces

- Monitor furnace temperatures

- Pour molten metal into ladles

3. Pour Molten Metal

Metal Molders pour molten metal into molds using ladles or other equipment. They must carefully control the flow of molten metal to ensure that it fills the mold completely.

- Control flow of molten metal

- Fill molds completely

- Remove excess molten metal

4. Inspect Castings

Metal Molders inspect castings for defects after they have cooled. They may use a variety of tools and equipment to check for cracks, voids, and other imperfections.

- Inspect castings for defects

- Use tools and equipment to check for cracks and voids

- Repair or discard defective castings

Interview Tips

Preparing for an interview can help you make a great impression on potential employers. Here are some tips to help you ace your interview for a Metal Molder position:

1. Research the Company

Before your interview, take some time to research the company you are applying to. This will help you understand their business, culture, and values. You can find information on the company’s website, social media pages, and news articles.

- Visit the company’s website

- Follow the company on social media

- Read news articles about the company

2. Practice Your Answers

Take some time to practice answering common interview questions. This will help you feel more confident and prepared during your interview. You can practice with a friend or family member, or you can use online resources to find sample interview questions and answers.

- Practice answering common interview questions

- Use online resources to find sample interview questions and answers

- Practice with a friend or family member

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the job you are applying for. You should also avoid wearing excessive jewelry or perfume.

- Wear clean, pressed clothes

- Dress appropriately for the job you are applying for

- Avoid wearing excessive jewelry or perfume

4. Be Punctual

Punctuality is important for any interview. Make sure to arrive for your interview on time, or even a few minutes early. This shows the interviewer that you are respectful of their time and that you are serious about the job.

- Arrive for your interview on time

- If possible, arrive a few minutes early

- This shows the interviewer that you are respectful of their time

5. Be Enthusiastic

Enthusiasm is contagious, so make sure to show the interviewer that you are excited about the job. Be positive and upbeat, and let the interviewer know why you are interested in the position.

- Be positive and upbeat

- Let the interviewer know why you are interested in the position

- Enthusiasm is contagious, so make sure to show the interviewer that you are excited about the job

6. Ask Questions

Asking questions at the end of the interview shows the interviewer that you are interested in the job and that you are taking the interview seriously. It also gives you an opportunity to learn more about the company and the position.

- Ask questions about the company

- Ask questions about the position

- Ask questions about the company’s culture

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Metal Molder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!