Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Plate Molder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

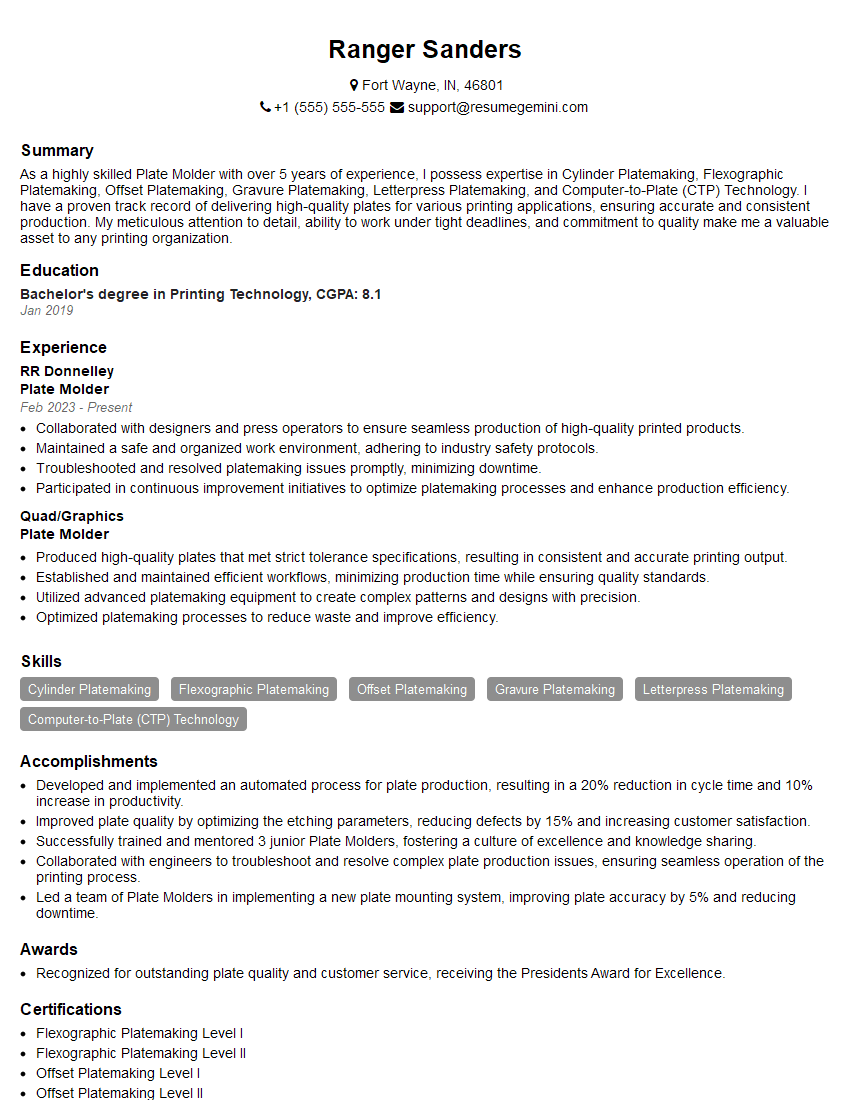

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plate Molder

1. What are the key responsibilities of a Plate Molder?

The key responsibilities of a Plate Molder include:

- Producing printing plates for use in printing presses

- Setting up and operating plate-making equipment

- Maintaining and calibrating equipment

- Inspecting plates for defects

- Working with customers to ensure satisfaction

2. What are the different types of printing plates?

Offset Plates

- Made of aluminum or polyester

- Image area is hydrophilic (water-loving)

- Non-image area is hydrophobic (water-repelling)

Gravure Plates

- Made of copper or steel

- Image area is recessed

- Non-image area is raised

Flexographic Plates

- Made of rubber or photopolymer

- Image area is raised

- Non-image area is recessed

3. What are the factors that affect the quality of a printing plate?

The factors that affect the quality of a printing plate include:

- The type of printing press being used

- The type of paper being used

- The ink being used

- The plate-making process

- The skill of the Plate Molder

4. What are the steps involved in the plate-making process?

- Prepress: Creating the digital file for the plate

- Platemaking: Exposing the plate to light to create the image

- Postpress: Developing and finishing the plate

5. What are the common problems that can occur during the plate-making process?

- Improper exposure

- Scratches or damage to the plate

- Chemical contamination

- Improper developing

- Improper finishing

6. How do you troubleshoot problems with the plate-making process?

To troubleshoot problems with the plate-making process, I follow these steps:

- Identify the problem

- Determine the cause of the problem

- Implement a solution

- Test the solution

- Monitor the results

7. What are the safety precautions that must be taken when working with plate-making chemicals?

The safety precautions that must be taken when working with plate-making chemicals include:

- Wear proper protective clothing, including gloves, eye protection, and a respirator

- Work in a well-ventilated area

- Do not ingest or inhale chemicals

- Dispose of chemicals properly

8. What are the latest trends in the plate-making industry?

- The use of digital plate-making technology

- The development of new plate materials

- The use of environmentally friendly plate-making chemicals

9. What is your experience with different types of plate-making equipment?

I have experience with a variety of plate-making equipment, including:

- Computer-to-plate (CTP) systems

- Direct-to-plate (DTP) systems

- Thermal plate processors

- UV plate processors

10. What is your quality control process for ensuring that plates meet customer specifications?

My quality control process for ensuring that plates meet customer specifications includes:

- Inspecting plates for defects

- Measuring plates to ensure that they meet dimensional specifications

- Testing plates on a press to ensure that they print correctly

- Maintaining records of all inspections and tests

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plate Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plate Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Plate Molders are responsible for creating printing plates, which are used in offset printing presses to transfer ink to paper or other surfaces. They work with a variety of materials, including metal, rubber, and plastic, and use specialized equipment to create high-quality plates that meet specific requirements.

1. Plate Preparation

Plate Molders prepare printing plates by cleaning and coating them with a light-sensitive emulsion. They then expose the emulsion to light through a negative or positive film, creating an image on the plate.

- Clean and prepare printing plates for imaging.

- Apply light-sensitive emulsions to plates.

- Expose plates to light through negatives or positives.

2. Plate Development

After exposure, Plate Molders develop the plates by washing away unexposed emulsion. This reveals the image on the plate, which can then be used to transfer ink to paper.

- Develop plates by washing away unexposed emulsion.

- Inspect plates for defects and make necessary corrections.

- Prepare plates for printing by applying ink and other materials.

3. Plate Maintenance

Plate Molders maintain plates by cleaning and repairing them as needed. They also store plates properly to prevent damage.

- Clean and repair plates as needed.

- Store plates properly to prevent damage.

4. Quality Control

Plate Molders ensure the quality of plates by inspecting them for defects and ensuring they meet customer specifications. They also troubleshoot problems with plates and make adjustments as needed.

- Inspect plates for defects and ensure they meet customer specifications.

- Troubleshoot problems with plates and make adjustments as needed.

- Maintain records of plate production and quality control.

Interview Tips

Preparing for an interview for a Plate Molder position can be daunting, but by following these tips, you can increase your chances of success.

1. Research the Company and the Position

Take the time to learn about the company and the specific role you are applying for. This will help you understand the company’s culture and the Anforderungen of the job.

- Visit the company’s website and social media pages.

- Read industry publications and news articles.

- Talk to people in your network who work in the printing industry.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice answering these questions in a clear and concise manner.

- Use the STAR method to answer behavioral questions.

- Be prepared to talk about your experience and skills.

- Quantify your accomplishments whenever possible.

3. Be Prepared to Talk About Your Experience

The interviewer will want to know about your experience in the printing industry. Be sure to highlight your skills and experience in plate making, as well as any other relevant experience you may have.

- Discuss your experience with different types of printing plates.

- Describe your skills in plate preparation, development, and maintenance.

- Explain your understanding of quality control procedures.

4. Ask Questions

Asking questions at the end of the interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the job and the company culture.

- Ask about the company’s growth plans.

- Inquire about the company’s commitment to quality.

- Ask about the training and development opportunities available.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Plate Molder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.