Are you gearing up for a career in Sand Slinger Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Sand Slinger Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

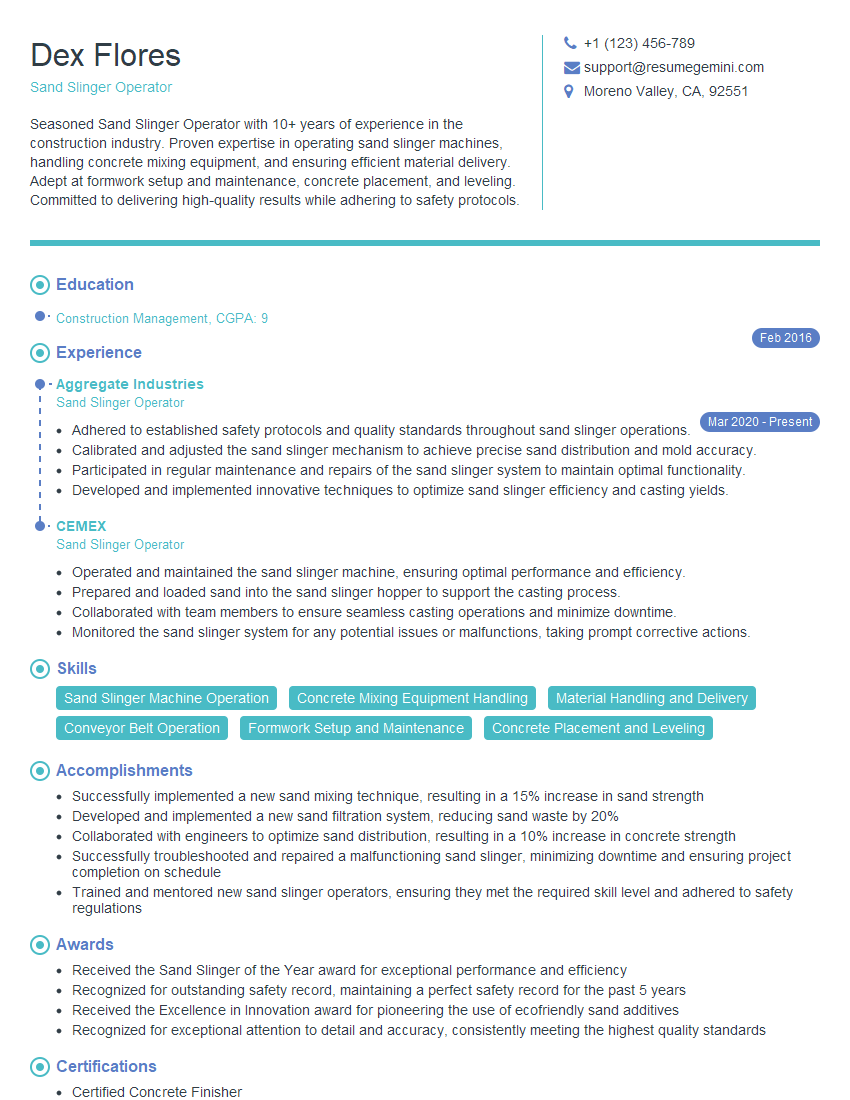

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sand Slinger Operator

1. How do you prepare the sand mixture for the slinger?

- I determine the correct ratio of sand, cement, and water based on the project specifications.

- I use a loader or conveyor to feed the materials into a mixer.

- I operate the mixer to thoroughly combine the ingredients until the mixture achieves the desired consistency.

2. How do you operate the sand slinger?

Positioning and Setup

- I position the slinger near the mold or casting area.

- I connect the slinger to the compressed air supply and power source.

- I adjust the angle and height of the slinger head to ensure proper coverage.

Operation

- I start the slinger and regulate the flow of sand using the control lever.

- I move the slinger head around the mold or casting area, distributing the mixture evenly.

- I use a hose or other tool to direct the sand into specific areas as needed.

3. How do you maintain the sand slinger?

- I regularly clean the slinger head, hose, and other components to remove any buildup.

- I check the air filters and replace them as necessary.

- I lubricate moving parts to ensure smooth operation.

- I perform routine inspections to identify any potential issues and make timely repairs.

4. What are the safety precautions to follow when operating a sand slinger?

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and a respirator.

- Ensure the area is well-ventilated to avoid inhaling harmful dust.

- Follow proper lockout/tagout procedures when servicing or repairing the slinger.

- Be aware of potential pinch points or moving parts that could cause injury.

- Never point the slinger head towards people or work areas.

5. How do you troubleshoot common problems with the sand slinger?

- If the slinger is not distributing sand properly, check the air pressure and hose connections.

- If the sand is not compacting properly, adjust the water content of the mixture or use a different type of sand.

- If the slinger is overheating, check the air filters and lubricate the moving parts.

- If the slinger is leaking air, check the hoses and connections for any damage.

6. What are the different types of sand slingers?

- Pneumatic Slingers: Use compressed air to propel the sand mixture.

- Mechanical Slingers: Use a rotating drum or impeller to distribute the sand.

- Combination Slingers: Combine both pneumatic and mechanical principles.

7. How do you calculate the amount of sand needed for a project?

- Determine the volume of the mold or casting area.

- Multiply the volume by the sand density (typically around 120 lbs/cubic foot).

- Adjust the amount based on the desired sand thickness and any compaction factors.

8. What are the factors that affect the quality of the sand slinging process?

- Sand Quality: Grain size, shape, and composition.

- Moisture Content: Affects the workability and strength of the sand.

- Air Pressure: Regulates the velocity and flow rate of the sand.

- Slinger Operation: Technique and skill of the operator.

- Environmental Conditions: Temperature, humidity, and wind.

9. How do you ensure the accuracy and consistency of the sand slinging process?

- Use precise measurements and calibrated equipment.

- Follow established procedures and specifications.

- Conduct regular quality checks and make adjustments as needed.

- Train and supervise operators to maintain high standards.

10. What are the applications of sand slingers in the industry?

- Foundry: Molding and casting.

- Construction: Shotcreting, concrete pumping.

- Mining: Ore transport.

- Abrasive Blasting: Sandblasting surfaces.

- Agriculture: Soil amendment and erosion control.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sand Slinger Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sand Slinger Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sand Slinger Operators are responsible for operating a sand slinger machine, which is used to apply a layer of sand to a surface. They play a crucial role in construction projects, road maintenance, and other applications where sand reinforcement or leveling is necessary.

1. Equipment Operation

Operate and maintain the sand slinger machine, ensuring its optimal performance.

- Control the flow and distribution of sand onto the targeted surface.

- Adjust machine settings to achieve desired sand coverage and thickness.

2. Surface Preparation

Prepare the work area by removing debris, leveling the surface, and applying any necessary primers or adhesives.

- Inspect the work area and identify any potential hazards or obstacles.

- Clear the surface of any loose materials or obstructions to ensure proper sand adhesion.

3. Sand Application

Apply the sand to the surface using the sand slinger machine, covering the designated area evenly and precisely.

- Monitor the sand flow and make adjustments as needed to achieve the desired sand layer thickness and texture.

- Ensure that the sand is applied to the correct specifications and quality standards.

4. Quality Control

Inspect the sand application to ensure it meets the required specifications and quality standards.

- Verify the sand coverage, thickness, and consistency using appropriate measuring tools.

- Identify and correct any defects or inconsistencies in the sand layer.

Interview Tips

Preparing for an interview for the position of Sand Slinger Operator requires a comprehensive understanding of the job responsibilities and a strategic approach to showcasing your skills and experience. Here are some essential tips to help you ace the interview:

1. Research the Company and Position

Thoroughly research the company and the specific role you are applying for. This knowledge will demonstrate your interest in the position and allow you to tailor your answers to the company’s needs.

- Visit the company’s website and social media pages to learn about their values, mission, and recent projects.

- Read industry publications and articles to gain insights into the field and identify any specific requirements or trends.

2. Highlight Your Experience and Skills

Emphasize your experience in operating and maintaining sand slinger machines. Quantify your accomplishments whenever possible to demonstrate the impact of your work.

- Describe projects where you successfully applied sand to large areas, ensuring precise coverage and thickness.

- Mention any certifications or training you have received in sand slinger operation or related fields.

3. Prepare for Common Interview Questions

Practice answering common interview questions related to sand slinger operation and construction practices. This will help you articulate your skills and experience confidently.

- Explain your understanding of the principles of sand application and how you ensure proper sand coverage.

- Describe the steps you take to prepare a work area for sand slinger operations and ensure surface readiness.

4. Demonstrate Your Commitment to Safety

Emphasize your commitment to safety and your understanding of the potential hazards associated with sand slinger operation.

- Discuss your experience in following safety protocols and adhering to industry regulations.

- Mention any safety initiatives or improvements you have implemented in previous roles.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sand Slinger Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!