Are you gearing up for an interview for a Shell Mold Bonding Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Shell Mold Bonding Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

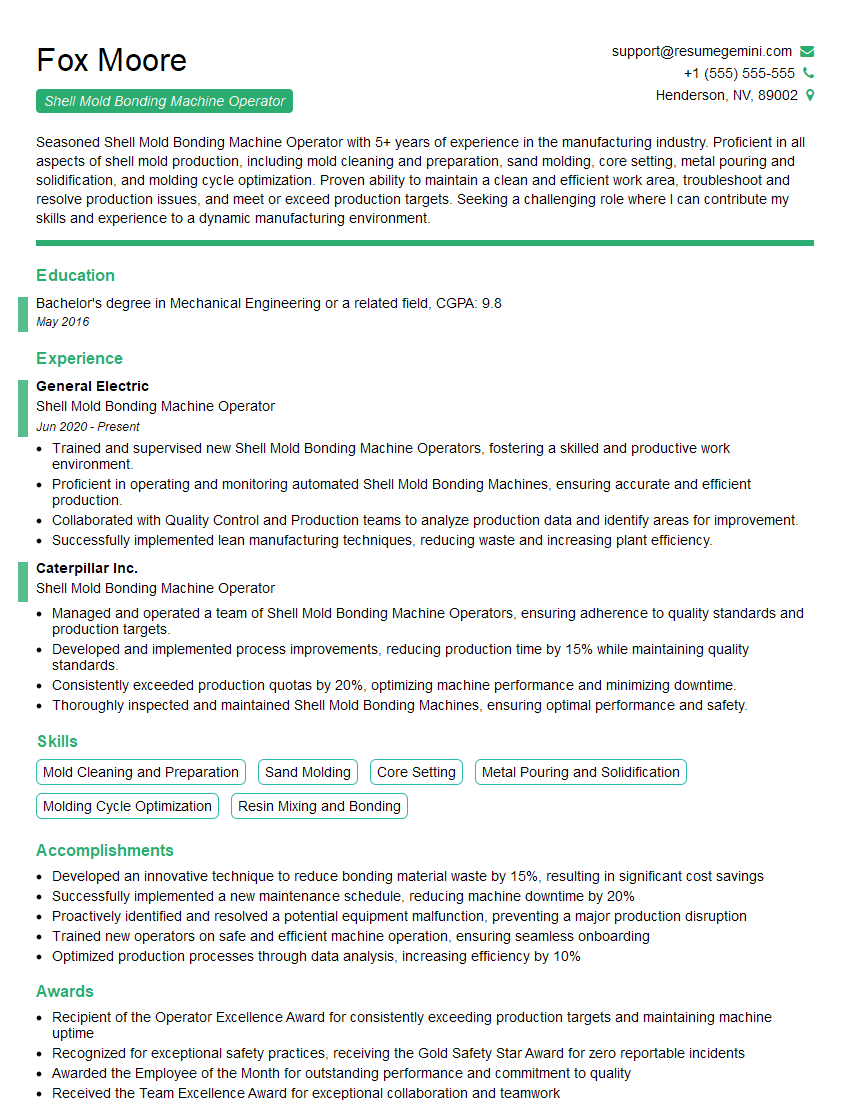

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Shell Mold Bonding Machine Operator

1. Describe the process of operating a Shell Mold Bonding Machine.

The process of operating a Shell Mold Bonding Machine involves the following steps:

- Loading the mold halves into the machine

- Applying a release agent to the mold surfaces

- Inserting the bonding material into the mold

- Closing the mold and applying pressure

- Curing the bonding material

- Removing the finished shell mold from the machine

2. What are the different types of bonding materials used in Shell Molding?

Thermosetting resins:

- Phenolic resins

- Epoxy resins

- Polyurethane resins

Thermoplastic resins:

- Polyethylene

- Polypropylene

- Polystyrene

3. What are the factors that affect the quality of a Shell Mold?

The quality of a Shell Mold is affected by the following factors:

- The type of bonding material used

- The amount of bonding material used

- The temperature of the curing process

- The pressure applied during curing

- The cooling rate after curing

4. What are the common defects that can occur in Shell Molds?

The following are some of the common defects that can occur in Shell Molds:

- Cracks

- Voids

- Warping

- Delamination

5. How can you troubleshoot a Shell Mold Bonding Machine?

Some troubleshooting tips for a Shell Mold Bonding Machine include:

- Checking the power supply

- Checking the hydraulic system

- Checking the mold temperature

- Checking the bonding material

- Checking the curing cycle

6. What is the role of a Shell Mold Bonding Machine Operator?

The role of a Shell Mold Bonding Machine Operator is to operate and maintain a Shell Mold Bonding Machine. Their responsibilities include:

- Loading and unloading the machine

- Setting up and monitoring the curing cycle

- Inspecting the finished molds

- Troubleshooting and repairing the machine

7. What are the safety precautions that must be followed when operating a Shell Mold Bonding Machine?

The following safety precautions must be followed when operating a Shell Mold Bonding Machine:

- Wear appropriate safety gear, including gloves, safety glasses, and a face shield.

- Keep the work area clean and free of debris.

- Do not operate the machine if it is damaged or if there are any loose parts.

- Follow the manufacturer’s instructions for operating the machine.

8. What is the importance of training and certification for Shell Mold Bonding Machine Operators?

Training and certification for Shell Mold Bonding Machine Operators is important for the following reasons:

- Ensures that operators are aware of the safety hazards associated with operating the machine.

- Provides operators with the knowledge and skills necessary to operate the machine safely and efficiently.

- Helps operators to identify and troubleshoot potential problems with the machine.

9. What are the advancement opportunities for Shell Mold Bonding Machine Operators?

Advancement opportunities for Shell Mold Bonding Machine Operators include:

- Becoming a supervisor or lead operator

- Moving into a quality control or engineering role

- Starting their own business

10. How do you stay up-to-date on the latest advancements in Shell Molding technology?

I stay up-to-date on the latest advancements in Shell Molding technology by:

- Reading industry publications

- Attending trade shows and conferences

- Networking with other professionals in the field

- Taking continuing education courses

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Shell Mold Bonding Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Shell Mold Bonding Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Shell Mold Bonding

Operate shell mold bonding machine to produce molds for casting metal parts.

- Load and unload molds into the machine.

- Apply resin and sand to the molds.

- Heat and cure the resin to bond the sand.

2. Machine Operation and Maintenance

Maintain and troubleshoot shell mold bonding machine.

- Inspect machine for any damages or malfunctions.

- Clean and lubricate machine as per manufacturer’s instructions.

- Report any issues or problems to supervisor.

3. Safety and Quality Control

Follow safety protocols and ensure the quality of the molds produced.

- Wear appropriate safety gear, such as gloves, safety glasses, and a respirator.

- Follow established procedures for handling hazardous materials.

- Inspect molds for any defects or imperfections.

4. Production and Efficiency

Meet production targets and maintain high levels of efficiency.

- Monitor production schedules and adjust machine settings to optimize output.

- Identify and implement ways to reduce waste and increase productivity.

- Collaborate with colleagues to ensure smooth workflow.

Interview Tips

1. Research the Company and Position

Thoroughly research the company, its values, and the specific requirements of the Shell Mold Bonding Machine Operator position.

- Visit the company website and social media pages.

- Read industry news and articles to understand the company’s market position.

- Review the job description carefully and note the key responsibilities and qualifications.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that are directly relevant to the position.

- Quantify your accomplishments and provide specific examples of your success in previous roles.

- Use action verbs and industry-specific terminology to demonstrate your expertise.

- Be prepared to discuss your knowledge of shell mold bonding machine operations and maintenance.

3. Prepare Questions for the Interviewers

Asking thoughtful questions shows that you are engaged and interested in the position.

- Inquire about the company’s growth prospects and industry outlook.

- Ask about the specific challenges and opportunities associated with the role.

- Seek clarification on any aspects of the job description that are unclear.

4. Practice and Rehearse

Practice your answers to common interview questions and rehearse your presentation.

- Mock interviews with a friend or family member can help you gain confidence.

- Record yourself answering questions to identify areas for improvement.

- Time yourself to ensure that you can answer questions concisely and within the allocated time.

5. Dress Professionally and Arrive on Time

Make a positive first impression by dressing professionally and arriving for your interview on time.

- Choose attire that is appropriate for the industry and company culture.

- Arrive a few minutes early to demonstrate respect for the interviewer’s time.

- Maintain a professional and courteous demeanor throughout the interview.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Shell Mold Bonding Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.