Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Turning and Beading Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

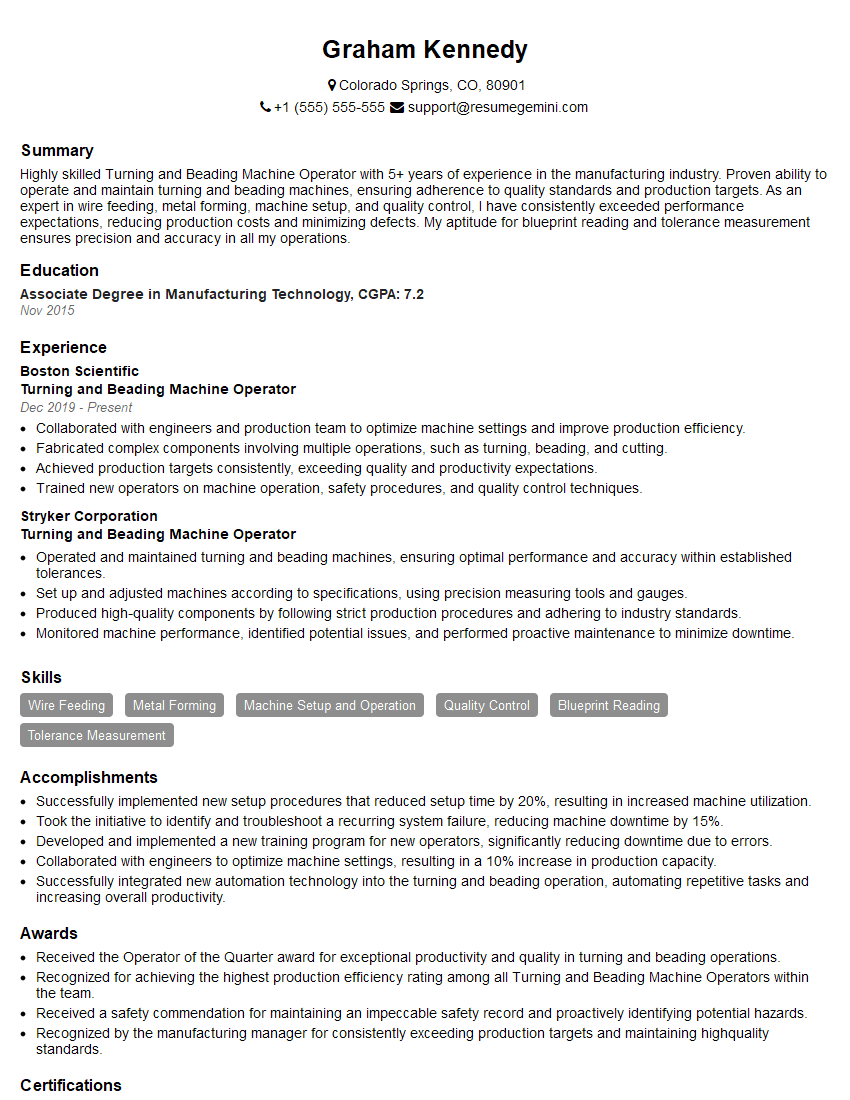

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Turning and Beading Machine Operator

1. Explain the key responsibilities of a Turning and Beading Machine Operator?

As a Turning and Beading Machine Operator, key responsibilities include:

- Setting up and operating turning and beading machines to shape and form metal components

- Ensuring that machine settings and parameters meet product specifications

- Loading and unloading workpieces, monitoring machine operations, and making necessary adjustments

- Inspecting finished products for quality and accuracy

- Maintaining a clean and organized work area

2. Describe the steps involved in setting up a turning and beading machine?

Preparation

- Secure the workpiece in the chuck or fixture

- Select and install the appropriate tooling

- Set machine speed, feed rate, and depth of cut

Operation

- Start the machine and monitor its operation

- Make adjustments to machine settings as needed

- Stop the machine when the operation is complete

3. How do you ensure that the finished products meet the required specifications?

To ensure that finished products meet specifications, I typically follow these steps:

- Thoroughly review the product specifications and drawings

- Set up the machine according to the specifications

- Inspect the products during and after production

- Make adjustments to the machine or process as needed

- Document the inspection results and any adjustments made

4. What are some common problems that can occur during turning and beading operations, and how do you troubleshoot them?

- Chatter: Caused by excessive vibration. Adjust machine settings, check workpiece securement, and ensure proper tooling selection.

- Tool breakage: Caused by incorrect tool selection, dull tools, or excessive cutting forces. Replace tools, adjust settings, and inspect for workpiece defects.

- Surface finish issues: Caused by improper tool condition, incorrect feed rate, or workpiece material issues. Adjust machine parameters, sharpen or replace tools, and check workpiece quality.

- Dimensional inaccuracies: Caused by incorrect machine setup, tool wear, or workpiece movement. Re-check machine settings, inspect tools, and ensure proper workpiece securement.

5. What maintenance tasks are typically performed on turning and beading machines?

- Lubricating moving parts

- Cleaning and inspecting machine components

- Replacing worn or damaged parts

- Calibrating and adjusting machine settings

- Following manufacturer’s maintenance schedule

6. How do you ensure that the work area is safe and organized?

- Keep the work area clean and free of debris

- Store tools and materials in designated areas

- Follow proper lockout/tagout procedures

- Wear appropriate safety gear

- Report any potential hazards or safety concerns

7. Describe your experience with different types of turning and beading machines.

I have experience operating various types of turning and beading machines, including:

- CNC turning machines

- Manual lathes

- Turret lathes

- Beading machines

- Roll forming machines

8. What safety precautions should be taken when operating turning and beading machines?

- Wear appropriate safety gear, including eye protection, ear protection, and gloves

- Securely fasten loose clothing and long hair

- Keep hands away from moving parts

- Never operate a machine while under the influence of drugs or alcohol

- Follow all manufacturer’s safety instructions

9. How do you handle situations where the machine malfunctions or there is a production problem?

- Stop the machine immediately

- Identify the problem and determine its cause

- Take corrective action to resolve the issue

- Notify the supervisor or maintenance personnel as necessary

- Document the incident and any actions taken

10. What are your career goals and how does this position align with them?

My career goal is to become a skilled and experienced machinist. This position as a Turning and Beading Machine Operator provides an excellent opportunity for me to develop my skills, gain valuable experience, and contribute to the success of your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Turning and Beading Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Turning and Beading Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Turning and Beading Machine Operators are responsible for setting up, operating, and maintaining turning and beading machines to create metal products. Some of the key job responsibilities involved in this role include:

1. Setup and Operation of Machinery

This involves:

- Installing and securing raw materials (e.g., metal sheets, rods, tubes) onto the machine.

- Setting up and adjusting machine parameters (e.g., speed, feed rate, tooling) to meet production specifications.

- Starting, monitoring, and stopping the machines throughout the production process.

2. Quality Control and Inspection

This involves:

- Inspecting raw materials to ensure they meet required specifications.

- Monitoring the production process to identify and correct any defects or inconsistencies.

- Performing quality checks on finished products to ensure they meet customer requirements.

3. Maintenance and Troubleshooting

This involves:

- Performing regular maintenance tasks (e.g., lubrication, cleaning, calibration) to keep machines running smoothly.

- Troubleshooting and resolving any technical issues or malfunctions that may arise.

- Reporting any significant problems or maintenance needs to supervisors or maintenance personnel.

4. Production and Efficiency

This involves:

- Meeting production targets and deadlines effectively.

- Optimizing machine settings and processes to increase productivity and reduce downtime.

- Working efficiently and safely in a fast-paced manufacturing environment.

Interview Tips

To ace an interview for a Turning and Beading Machine Operator position, consider the following tips:

1. Research the Company and Industry

Research the company’s background, products or services, and industry trends. This will demonstrate your interest in the role and the company.

2. Highlight Relevant Experience and Skills

Emphasize your hands-on experience in operating and maintaining turning and beading machines. Quantify your accomplishments and provide specific examples of your contributions.

3. Prepare for Technical Questions

Be prepared to answer questions about machine setup, troubleshooting, and quality control procedures. Demonstrate your understanding of the technical aspects of the job.

4. Emphasize Safety and Attention to Detail

Highlight your commitment to following safety protocols and maintaining a high level of attention to detail. These qualities are crucial in manufacturing environments.

5. Show Your Teamwork and Communication Skills

Turning and Beading Machine Operators often work in teams. Highlight your ability to collaborate with others, communicate effectively, and resolve issues as part of a team.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Turning and Beading Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Turning and Beading Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.