Feeling lost in a sea of interview questions? Landed that dream interview for Vacuum Plastic Forming Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Vacuum Plastic Forming Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

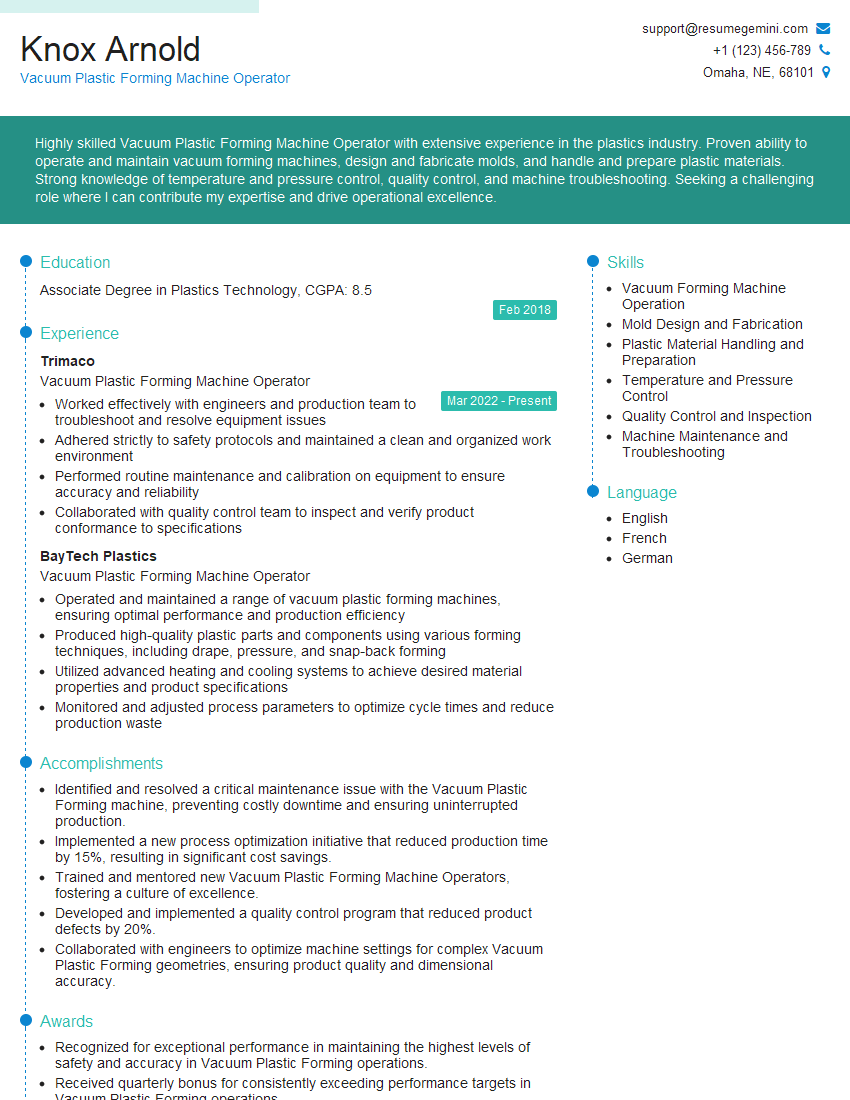

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Vacuum Plastic Forming Machine Operator

1. What are the key responsibilities of a Vacuum Plastic Forming Machine Operator?

As a Vacuum Plastic Forming Machine Operator, I would be responsible for:

- Operating and maintaining vacuum plastic forming machines to manufacture plastic products

- Setting up and adjusting the machine according to production requirements

- Loading and unloading plastic sheets and molds

- Monitoring the forming process and making necessary adjustments

- Ensuring the quality of the finished products

- Performing routine maintenance and troubleshooting

2. What types of plastic materials are commonly used in vacuum plastic forming?

- Polyethylene (PE)

- Polypropylene (PP)

- Polystyrene (PS)

- Polyvinyl chloride (PVC)

- Polyethylene terephthalate (PET)

The type of plastic material used depends on the specific product requirements, such as strength, flexibility, and temperature resistance.

3. Explain the steps involved in the vacuum plastic forming process.

The vacuum plastic forming process typically involves the following steps:

- Heating the plastic sheet to a pliable state

- Stretching the heated plastic sheet over a mold

- Applying vacuum to the mold to draw the plastic sheet into the mold’s shape

- Cooling the plastic sheet to solidify it in the desired shape

- Trimming and finishing the formed plastic product

4. What are the different types of vacuum plastic forming machines?

- Single-station machines

- Multi-station machines

- Shuttle machines

- Rotary machines

The type of machine used depends on the production volume and the complexity of the plastic products being manufactured.

5. What are the safety precautions that should be taken when operating a vacuum plastic forming machine?

- Wear appropriate personal protective equipment (PPE), such as gloves and safety glasses

- Keep the work area clean and free of debris

- Never operate the machine without proper training

- Be aware of the potential hazards, such as hot surfaces and moving parts

- Follow all safety procedures and guidelines

6. What are some common troubleshooting tips for vacuum plastic forming machines?

- Check the vacuum pump to ensure it is working properly

- Inspect the mold for any damage or wear

- Check the heating elements to ensure they are functioning correctly

- Calibrate the machine to ensure accurate forming

- Refer to the manufacturer’s instructions for specific troubleshooting procedures

7. What are the quality control checks that should be performed on the finished plastic products?

- Inspect the products for any defects, such as cracks, scratches, or bubbles

- Measure the products to ensure they meet the required dimensions

- Test the products to ensure they meet the required performance specifications

- Maintain records of all quality control checks

8. What are some tips for optimizing the efficiency of vacuum plastic forming machines?

- Use the correct mold for the specific plastic product

- Set the machine parameters to the optimal settings

- Keep the machine clean and well-maintained

- Use high-quality plastic materials

- Minimize downtime by scheduling regular maintenance

9. What are some common challenges faced by Vacuum Plastic Forming Machine Operators?

- Maintaining consistent product quality

- Troubleshooting machine malfunctions

- Meeting production deadlines

- Working with a variety of materials

- Keeping up with new technology

10. What are your career goals as a Vacuum Plastic Forming Machine Operator?

My career goals are to:

- Become a highly skilled and experienced Vacuum Plastic Forming Machine Operator

- Contribute to the success of the company by producing high-quality plastic products

- Advance in my career by taking on additional responsibilities and challenges

- Stay up-to-date with the latest technology and best practices in the field

- Make a positive impact on the industry

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Vacuum Plastic Forming Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Vacuum Plastic Forming Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Vacuum Plastic Forming Machine Operator is responsible for operating and maintaining vacuum plastic forming machines to produce plastic products. The key job responsibilities include:

1. Machine Operation

Setting up and operating vacuum plastic forming machines according to production schedules.

- Loading plastic sheets into the machine and positioning them for forming.

- Activating the vacuum and heating systems to form the plastic into molds.

- Unloading formed plastic products from the machine.

2. Quality Control

Inspecting formed plastic products for quality and defects.

- Checking dimensions, thickness, and surface finish to ensure they meet specifications.

- Identifying and marking any defective products for rework or rejection.

- Maintaining quality records and reporting any quality issues.

3. Machine Maintenance

Performing basic maintenance and troubleshooting on vacuum plastic forming machines.

- Cleaning and lubricating machine parts.

- Replacing worn or damaged parts.

- Calibrating and adjusting machine settings.

- Reporting major maintenance issues to supervisors.

4. Production Monitoring

Monitoring production schedules and ensuring timely completion of orders.

- Tracking production output and reporting any delays or production issues.

- Adjusting machine settings to optimize production efficiency.

- Coordinating with other team members to ensure smooth production flow.

Interview Tips

To prepare for a vacuum plastic forming machine operator interview, candidates should focus on highlighting their skills and experience in machine operation, quality control, and production monitoring. Here are some tips:

1. Research the Company and Role

Before the interview, research the company and the specific role you are applying for. This will help you understand the company’s culture, products, and the requirements of the job.

- Visit the company’s website to learn about their business, products, and values.

- Review the job description carefully to identify the key responsibilities and qualifications required.

2. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers. This will help you feel more confident and articulate during the interview.

- Prepare for questions about your experience in operating vacuum plastic forming machines.

- Practice describing your quality control procedures and how you ensure the production of high-quality products.

- Be ready to discuss your problem-solving skills and how you handle production issues.

3. Highlight Your Skills and Experience

During the interview, emphasize your skills and experience that are relevant to the role.

- Provide specific examples of your experience in operating vacuum plastic forming machines.

- Describe your quality control procedures and how you maintain high production standards.

- Highlight your ability to troubleshoot and resolve production issues quickly and effectively.

4. Be Enthusiastic and Professional

Throughout the interview, maintain a positive and enthusiastic attitude. Show that you are interested in the role and the company.

- Dress professionally and arrive on time for the interview.

- Make eye contact, speak clearly, and be respectful to the interviewer.

- Ask thoughtful questions to demonstrate your interest and understanding of the role.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Vacuum Plastic Forming Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Vacuum Plastic Forming Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.