Feeling lost in a sea of interview questions? Landed that dream interview for Combination Machine Tool Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Combination Machine Tool Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

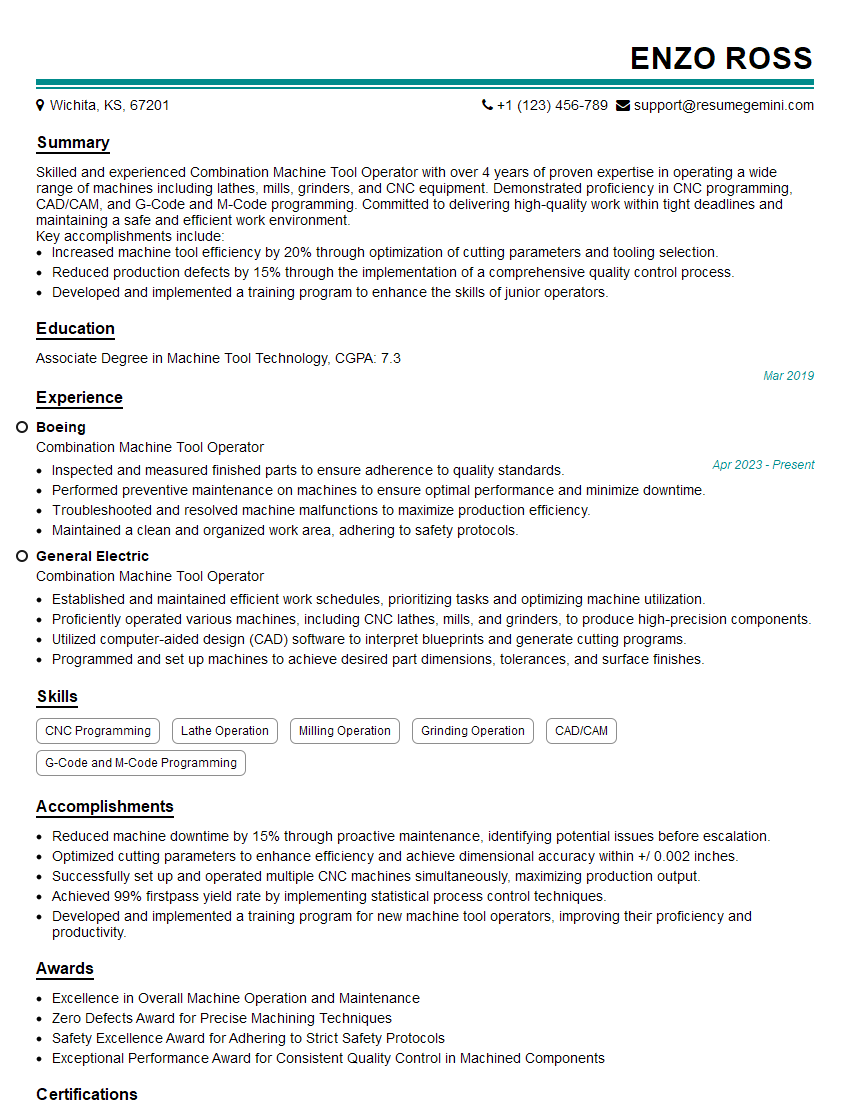

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Combination Machine Tool Operator

1. Describe the key responsibilities of a Combination Machine Tool Operator.

- Setting up, operating, and maintaining various machine tools, such as lathes, mills, grinders, and drilling machines.

- Interpreting blueprints and work orders to determine job requirements.

- Selecting and using appropriate cutting tools and materials.

- Inspecting finished products to ensure they meet specifications.

- Maintaining a clean and organized work area.

2. What is the difference between a lathe and a mill?

Lathe

- Used for turning cylindrical workpieces.

- The workpiece rotates while the cutting tool moves along the z-axis.

- Can be used for a variety of operations, such as turning, facing, and grooving.

Mill

- Used for machining flat surfaces.

- The cutting tool moves along the x- and y-axes while the workpiece remains stationary.

- Can be used for a variety of operations, such as milling, drilling, and boring.

3. What are the different types of cutting tools used in machining?

- Single-point cutting tools: Used for turning, facing, and grooving.

- Multi-point cutting tools: Used for milling, drilling, and boring.

- Abrasive cutting tools: Used for grinding and polishing.

- Carbide cutting tools: Used for high-speed machining.

- Diamond cutting tools: Used for machining hard materials.

4. What is the importance of coolant in machining?

- Reduces friction between the cutting tool and the workpiece.

- Removes heat from the cutting zone.

- Prevents chips from clogging the cutting tool.

- Improves the surface finish of the machined product.

- Extends the life of the cutting tool.

5. What are the safety precautions that must be taken when operating machine tools?

- Always wear appropriate safety gear, such as safety glasses, gloves, and a lab coat.

- Ensure that the machine is properly grounded.

- Never operate a machine that is not in good working condition.

- Keep the work area clean and free of clutter.

- Be aware of the location of all emergency stop buttons.

6. What is your experience with CNC machines?

- Worked with CNC machines for the past 5 years.

- Proficient in programming and operating CNC lathes and mills.

- Experience with a variety of CNC software.

- Familiar with CNC machine maintenance and troubleshooting.

7. What is your strongest skill as a machinist?

8. What is your weakest skill as a machinist?

9. What are your career goals?

10. Why are you interested in this position?

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Combination Machine Tool Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Combination Machine Tool Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Combination Machine Tool Operators are skilled professionals responsible for operating and maintaining a variety of machine tools to produce precision parts and products. Their primary duties encompass:

1. Machine Operation

- Set up and operate a wide range of machine tools, including lathes, mills, grinders, and CNC machines, to produce parts according to specifications.

- Interpret blueprints, drawings, and written instructions to determine appropriate machining techniques and equipment.

- Select and use appropriate tools, cutting fluids, and workholding devices to achieve optimal results.

2. Quality Control

- Inspect and verify the dimensions, tolerances, and finish of machined parts using precision measuring devices.

- Identify and correct any deviations or defects during the machining process to ensure product quality.

- Adhere to established quality standards and procedures to maintain consistent outputs.

3. Machine Maintenance

- Perform routine maintenance and calibration on machine tools to ensure optimal performance.

- Lubricate, clean, and adjust machines as needed to minimize downtime and extend machine life.

- Troubleshoot and repair minor machine malfunctions to maintain productivity.

4. Safety Compliance

- Follow established safety protocols and wear appropriate personal protective equipment (PPE) while operating machinery.

- Maintain a clean and organized work area to prevent accidents and injuries.

- Adhere to all applicable safety regulations and participate in safety training programs.

Interview Tips

To ace the interview for a Combination Machine Tool Operator position, it is crucial to:

1. Research the Company and Position

- Familiarize yourself with the company’s industry, products or services, and culture.

- Thoroughly review the job description to understand the specific requirements of the role.

2. Highlight Relevant Skills and Experience

- Emphasize your proficiency in operating various machine tools, including CNC machines.

- Showcase your knowledge of quality control procedures and your ability to interpret blueprints.

- Provide examples of successful troubleshooting and repair experiences.

3. Demonstrate Safety Consciousness

- Stress your commitment to following safety protocols and maintaining a safe work environment.

- Share any certifications or training related to safety practices.

4. Prepare for Technical Questions

- Anticipate questions about different machine tool operations, cutting techniques, and measurement tools.

- Practice describing your problem-solving approach and your ability to handle unexpected situations.

5. Be Punctual and Professional

- Arrive on time for the interview and dress appropriately.

- Be polite and respectful to the interviewer and ask thoughtful questions.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Combination Machine Tool Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Combination Machine Tool Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.