Are you gearing up for a career in Gear Shaper Set-Up Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Gear Shaper Set-Up Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

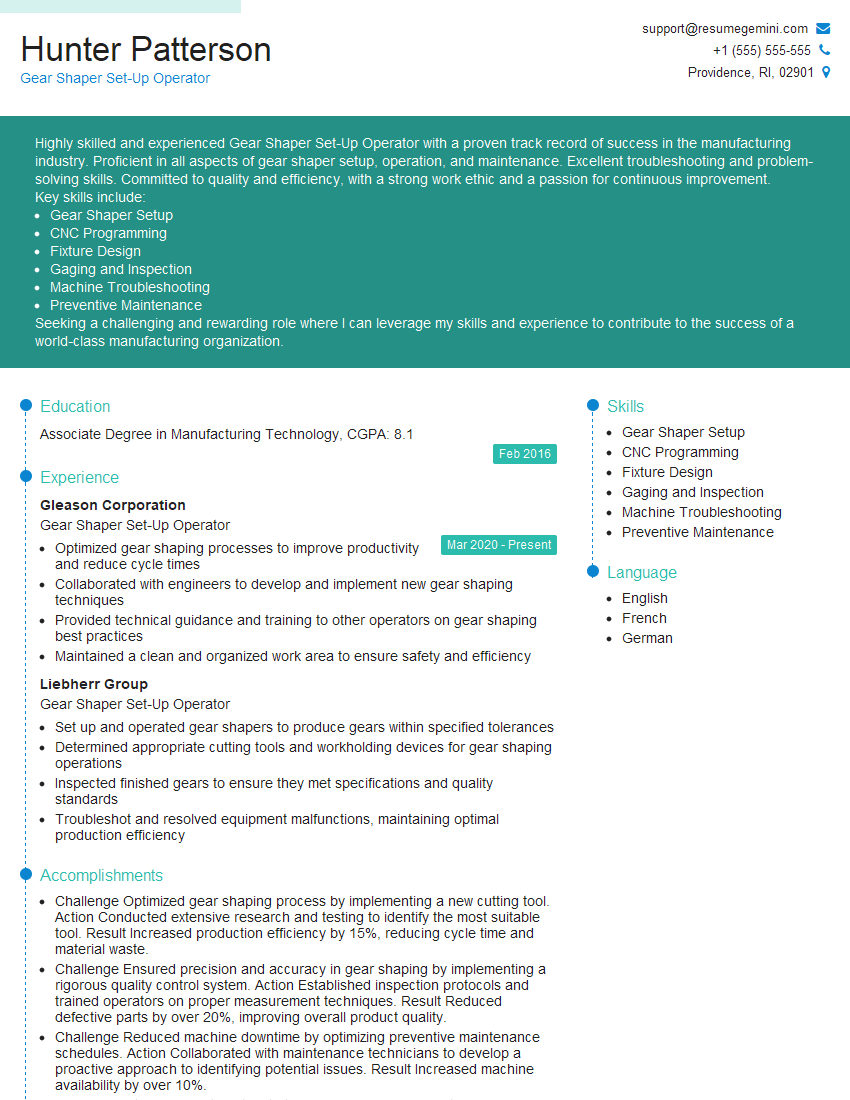

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gear Shaper Set-Up Operator

1. What are the key responsibilities of a Gear Shaper Set-Up Operator?

As a Gear Shaper Set-Up Operator, my primary responsibilities include:

- Setting up and operating gear shaping machines to produce gears and other components

- Selecting and mounting the appropriate cutting tools and fixtures

- Establishing and maintaining optimal operating parameters, including speed, feed, and depth of cut

- Monitoring the cutting process and making adjustments as needed

- Inspecting finished gears and components to ensure they meet specifications

2. Describe the different types of gear shaping machines you have experience with.

Horizontal Gear Shaping Machines:

- Used for cutting external gears

- Feature a horizontally mounted ram and table

Vertical Gear Shaping Machines:

- Used for cutting internal gears

- Feature a vertically mounted ram and table

Universal Gear Shaping Machines:

- Can be used for cutting both external and internal gears

- Feature a rotating table that allows for multiple setups

3. What are the critical parameters to consider when setting up a gear shaping machine?

When setting up a gear shaping machine, it is crucial to consider the following parameters:

- Gear specifications (number of teeth, pitch, pressure angle, etc.)

- Machine capabilities (maximum gear size, spindle speed, etc.)

- Cutting tool selection (type, material, geometry, etc.)

- Fixture selection (type, size, mounting method, etc.)

- Operating parameters (speed, feed, depth of cut, etc.)

4. How do you ensure the accuracy and precision of the gears produced on a gear shaping machine?

To ensure the accuracy and precision of the gears produced on a gear shaping machine, I follow these steps:

- Use precision measuring tools to calibrate the machine and cutting tools

- Select the appropriate cutting speed and feed rate based on the material and gear specifications

- Monitor the cutting process closely and make adjustments as needed

- Inspect the finished gears using a gear tooth comparator or other precision measuring equipment

5. What are some common problems that can occur during gear shaping operations and how do you resolve them?

Some common problems that can occur during gear shaping operations include:

- Chattering: This can be caused by excessive vibration or improper setup. I resolve it by adjusting the cutting parameters, inspecting the machine for loose components, and ensuring the workpiece is securely fixtured.

- Tooth breakage: This can be caused by using dull cutting tools or excessive cutting forces. I resolve it by replacing the cutting tools, reducing the feed rate, or adjusting the depth of cut.

- Inaccurate gear profile: This can be caused by improper setup or worn cutting tools. I resolve it by recalibrating the machine, replacing the cutting tools, and checking the accuracy of the workpiece.

6. What maintenance procedures are essential for keeping a gear shaping machine in optimal condition?

To keep a gear shaping machine in optimal condition, I perform the following maintenance procedures:

- Regularly clean and lubricate the machine

- Inspect the cutting tools for wear and damage

- Check the machine’s calibration and accuracy

- Perform preventive maintenance tasks as recommended by the manufacturer

7. What safety precautions are essential when operating a gear shaping machine?

When operating a gear shaping machine, I always prioritize safety by following these precautions:

- Wear appropriate personal protective equipment (PPE)

- Ensure the machine is properly guarded and interlocked

- Keep the work area clean and free of debris

- Never operate the machine under the influence of drugs or alcohol

- Follow all established safety procedures and protocols

8. How do you stay updated on the latest advancements in gear shaping technology?

To stay updated on the latest advancements in gear shaping technology, I engage in the following practices:

- Attend industry conferences and seminars

- Read technical journals and white papers

- Consult with vendors and equipment manufacturers

- Network with other gear shaping professionals

9. What are your strengths and weaknesses as a Gear Shaper Set-Up Operator?

My strengths as a Gear Shaper Set-Up Operator include:

- Strong understanding of gear shaping principles and best practices

- Proficient in setting up, operating, and maintaining gear shaping machines

- Excellent attention to detail and precision

- Ability to troubleshoot and resolve technical issues independently

- Experience in working in a team environment

As for my weaknesses, I am always seeking opportunities for professional development, particularly in the areas of:

- Advanced gear shaping techniques

- CNC programming and automation

- Quality control and inspection methods

10. Why are you interested in this Gear Shaper Set-Up Operator position?

I am eager to join your team as a Gear Shaper Set-Up Operator because I am confident that my skills and experience would be a valuable asset to your organization. I am particularly excited about the opportunity to contribute to your company’s reputation for producing high-quality gears and components.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gear Shaper Set-Up Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gear Shaper Set-Up Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Gear Shaper Set-Up Operators are responsible for setting up and operating gear shaper machines to cut gears for a variety of applications. Key responsibilities include:

1. Machine Setup and Operation

Set up and operate gear shaper machines according to specifications, ensuring that they are properly calibrated and adjusted.

- Install and align cutting tools, fixtures, and workpieces.

- Select and set appropriate cutting parameters, feed rates, and speeds.

- Monitor machine operation and make adjustments as needed to optimize cutting efficiency and accuracy.

2. Quality Control

Inspect gears for quality and accuracy using measuring tools and gauges.

- Identify and correct any defects or deviations from specifications.

- Maintain records of inspection results and take corrective action as necessary.

- Calibrate and maintain measuring equipment to ensure accuracy and reliability.

3. Maintenance and Troubleshooting

Perform routine maintenance and troubleshooting on gear shaper machines.

- Identify and replace worn or damaged parts.

- Lubricate and adjust moving parts to ensure smooth operation.

- Resolve machine malfunctions and minimize downtime.

4. Production Optimization

Continuously seek ways to improve production efficiency and minimize waste.

- Identify and eliminate bottlenecks in the production process.

- Experiment with different cutting techniques and parameters to optimize performance.

- Train and mentor other operators to enhance overall productivity.

Interview Tips

To ace an interview for a Gear Shaper Set-Up Operator position, it’s essential to prepare thoroughly and demonstrate your technical skills, experience, and problem-solving abilities. Here are some tips:

1. Research the Company and Industry

Learn about the company’s products, services, and target market. Familiarize yourself with the specific industry and equipment used in gear manufacturing.

- Visit the company website and social media pages.

- Read industry publications and articles.

- Attend industry events or webinars.

2. Practice Common Interview Questions

Be prepared to answer general interview questions, such as “Tell me about yourself” and “Why are you interested in this position?” Additionally, practice technical questions related to gear shaping machines, such as:

- Explain the different types of gear shaper machines and their applications.

- Describe the process of setting up and operating a gear shaper machine.

- How do you ensure the accuracy and quality of gears produced on a gear shaper machine?

3. Highlight Your Experience and Skills

Emphasize your relevant experience in operating or setting up gear shaper machines. Showcase your ability to troubleshoot and maintain equipment, and your commitment to quality and productivity.

- Quantify your accomplishments using specific metrics, such as “Reduced machine downtime by 15%” or “Improved gear quality by 5%.”

- Use examples from previous roles to demonstrate your problem-solving and decision-making abilities.

- Be prepared to discuss your knowledge of different cutting tools, materials, and machining techniques.

4. Ask Informed Questions

Asking insightful questions during the interview shows your interest and engagement. Prepare thoughtful questions related to the company, the position, or the industry.

- Ask about the company’s growth plans and future projects.

- Inquire about the specific responsibilities and challenges of the Gear Shaper Set-Up Operator role.

- Ask about the company’s commitment to training and professional development.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Gear Shaper Set-Up Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!