Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Production Machine Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

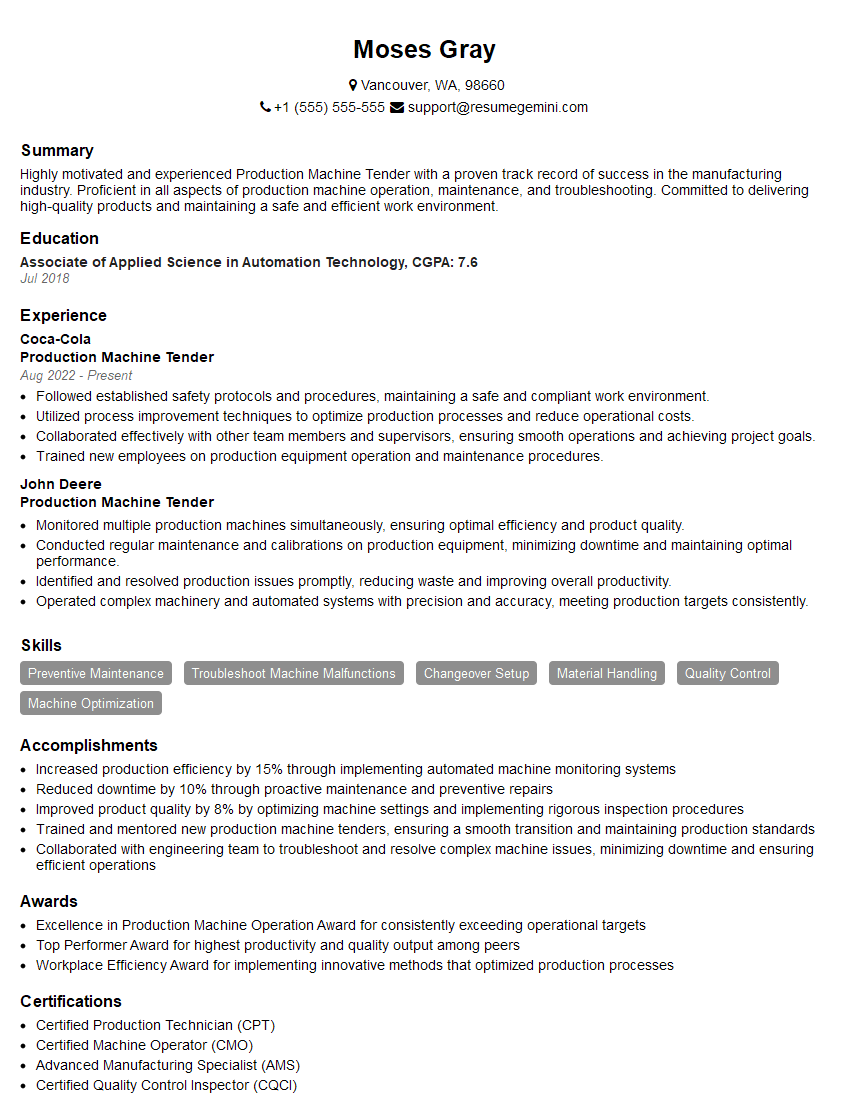

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Production Machine Tender

1. How do you prioritize and manage multiple production orders simultaneously?

- Review work orders and determine the order of importance.

- Consider the lead time, customer deadlines, and resource availability.

- Coordinate with other departments (e.g., engineering, purchasing) to ensure timely material and component delivery.

- Monitor production progress and make adjustments as needed to maintain efficiency.

2. What are the key steps involved in machine setup and changeover?

Machine Preparation

- Power down the machine and lock out/tag out.

- Clear the work area and prepare tools and fixtures.

Tooling Setup

- Install new tooling, jigs, and fixtures.

- Calibrate and test tools to ensure accuracy.

Program Optimization

- Review and modify program parameters (e.g., feed rates, spindle speeds).

- Run test parts to verify program accuracy.

3. How do you troubleshoot and resolve production issues efficiently?

- Identify the problem and determine the root cause.

- Consult technical documentation, manuals, and resources.

- Inspect the machine, tools, and materials for defects or malfunctions.

- Implement solutions (e.g., adjusting settings, replacing components) to resolve the issue.

4. Describe your experience with statistical process control (SPC) techniques.

- Collect and analyze data (e.g., measurements, cycle times) using SPC charts.

- Identify trends, patterns, and outliers in the process.

- Implement corrective actions to maintain process stability and improve product quality.

- Communicate findings and recommendations to relevant stakeholders.

5. How do you ensure the accuracy of production parts and maintain quality standards?

- Follow established quality control procedures and protocols.

- Conduct regular inspections and measurements using gauges, calipers, and other tools.

- Calibrate and maintain measuring equipment to ensure accuracy.

- Identify and correct deviations from specifications promptly.

6. What is your experience with preventive maintenance and how do you contribute to it?

- Follow established maintenance schedules and checklists.

- Inspect equipment for signs of wear, damage, or malfunction.

- Clean, lubricate, and adjust machines to minimize downtime.

- Report maintenance issues promptly and assist with repairs as needed.

7. Describe your understanding of machine safety protocols and how you implement them.

- Wear appropriate personal protective equipment (e.g., gloves, safety glasses).

- Understand and follow lockout/tag out procedures.

- Identify and avoid potential hazards (e.g., moving parts, sharp edges).

- Report any unsafe conditions or practices immediately.

8. What is your experience with automation and how do you leverage it to improve productivity?

- Familiar with robotic arms, conveyors, and other automated systems.

- Participate in the setup, programming, and maintenance of automation equipment.

- Identify opportunities to automate repetitive tasks and streamline production.

9. Describe a situation where you had to make a critical decision under pressure and how you handled it.

- Stay calm and assess the situation thoroughly.

- Gather information from relevant sources (e.g., colleagues, supervisors).

- Consider the potential consequences of different options.

- Make a decision based on sound judgment and technical expertise.

10. What are your career goals and how do you see this role contributing to them?

- Develop advanced skills in production machine operation and maintenance.

- Contribute to the improvement of production processes and quality standards.

- Advance to a supervisory or management role in the manufacturing industry.

- Utilize the knowledge and experience gained in this role to enhance my technical capabilities.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Production Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Production Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Production Machine Tenders are responsible for the smooth and efficient operation of production machinery. They ensure that machines are properly set up, calibrated, and maintained, and that production runs smoothly with minimal downtime. Key job responsibilities include:

1. Machine Setup and Maintenance

Setting up and calibrating production machines according to specifications

- Conducting regular maintenance and repairs to keep machines in optimal condition

- Troubleshooting and resolving technical issues

2. Production Monitoring and Control

Monitoring production processes to ensure they are running smoothly and efficiently

- Adjusting machine settings and parameters to optimize production

- Identifying and resolving any production issues promptly

- Maintaining production records and documentation

3. Quality Control

Inspecting finished products to ensure they meet quality standards

- Conducting statistical process control (SPC) to monitor and improve product quality

- Identifying and rectifying any quality defects

4. Safety and Compliance

Adhering to all safety regulations and procedures

- Maintaining a clean and organized work area

- Reporting any safety hazards or concerns promptly

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips to help you ace your Production Machine Tender interview:

1. Research the Company and Position

Take the time to learn about the company’s history, mission, and values. Research the specific role you are applying for and understand its key responsibilities and expectations.

- Visit the company’s website and social media pages

- Read industry publications and news articles

- Ask your network for any insights or connections

2. Practice Your Answers

Prepare for common interview questions by practicing your answers beforehand. This will help you feel more confident and articulate during the interview.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers

- Quantify your accomplishments whenever possible

- Tailor your answers to the specific job requirements

3. Dress Professionally and Arrive on Time

First impressions matter, so dress appropriately for the interview. Arrive on time to demonstrate your respect for the interviewer’s time.

- Wear clean, pressed business attire

- Be well-groomed and avoid strong scents

- Allow ample time for travel and parking

4. Be Enthusiastic and Positive

Convey your passion for the role and your ability to contribute to the company. Maintain a positive attitude and enthusiasm throughout the interview.

- Share your interest in the company and the industry

- Highlight your relevant skills and experience

- Express your willingness to learn and grow

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Production Machine Tender interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.