Are you gearing up for an interview for a Rim Technician position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Rim Technician and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

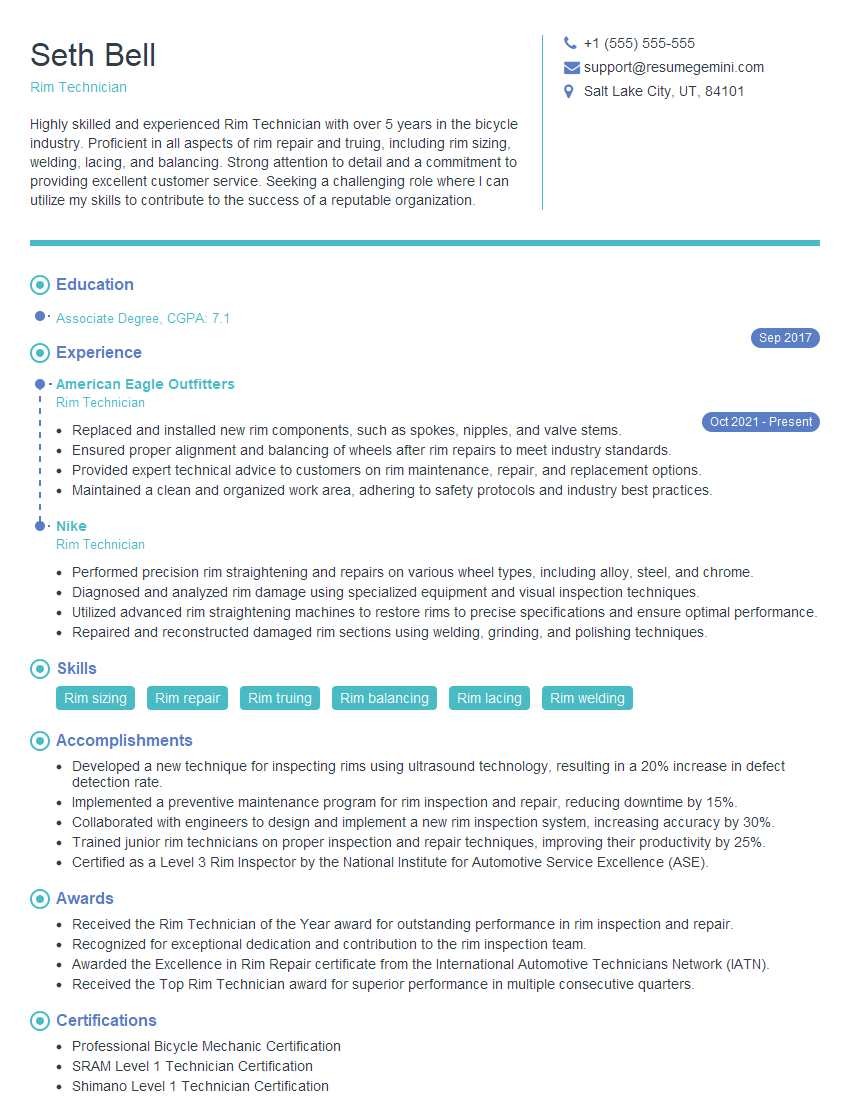

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rim Technician

1. Explain the process of wheel alignment and how it affects vehicle performance?

Wheel alignment is the process of adjusting the angles of the wheels so that they are perpendicular to the ground and parallel to each other. This is important for several reasons:

- Safety: Proper alignment helps to ensure that the vehicle tracks straight and does not pull to one side, which can be dangerous.

- Tire wear: Misaligned wheels can cause tires to wear unevenly, which can shorten their lifespan.

- Fuel efficiency: Properly aligned wheels can help to improve fuel efficiency by reducing rolling resistance.

- Handling: Proper alignment can help to improve the vehicle’s handling and stability.

2. What are the different types of wheel alignment adjustments that can be made?

Camber

- Positive camber is when the top of the wheel is tilted outward.

- Negative camber is when the top of the wheel is tilted inward.

Caster

- Positive caster is when the steering axis is tilted forward.

- Negative caster is when the steering axis is tilted backward.

Toe

- Toe-in is when the front of the wheels are closer together than the rear.

- Toe-out is when the front of the wheels are farther apart than the rear.

3. What are the symptoms of misaligned wheels?

- The vehicle pulls to one side when driving.

- The steering wheel is off-center when driving straight.

- The tires are wearing unevenly.

- The vehicle is difficult to control.

- The fuel economy is poor.

4. What are the causes of misaligned wheels?

- Hitting a curb or pothole.

- Worn or damaged suspension components.

- An accident.

- Improper wheel alignment.

5. What are the tools and equipment needed to perform a wheel alignment?

- Wheel alignment machine.

- Tire pressure gauge.

- Lug wrench.

- Socket set.

- Level.

6. What are the steps involved in performing a wheel alignment?

- Inspect the tires for wear and damage.

- Check the tire pressure.

- Place the vehicle on the alignment machine.

- Center the steering wheel.

- Adjust the camber, caster, and toe according to the vehicle’s specifications.

- Road test the vehicle to verify the alignment.

7. What are the benefits of having your wheels aligned?

- Improved safety.

- Increased tire life.

- Improved fuel efficiency.

- Enhanced handling and stability.

8. How often should you have your wheels aligned?

- Every 6 months or 12,000 miles.

- After hitting a curb or pothole.

- After an accident.

- If you notice any of the symptoms of misaligned wheels.

9. What is the difference between a wheel alignment and a tire balance?

- A wheel alignment adjusts the angles of the wheels so that they are perpendicular to the ground and parallel to each other.

- A tire balance adjusts the weight of the tire so that it rolls smoothly.

10. What are some common mistakes that can be made when performing a wheel alignment?

- Not using the correct equipment.

- Not following the vehicle’s specifications.

- Not road testing the vehicle after the alignment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rim Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rim Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rim Technicians are responsible for maintaining and repairing rims, which are the metal hoops that hold tires in place on vehicles. They work in a variety of settings, including tire shops, automotive repair shops, and manufacturing plants. Key responsibilities of a Rim Technician include:

1. Inspecting and diagnosing rims

Rim Technicians must be able to identify and diagnose problems with rims, such as cracks, dents, or bends. They use a variety of tools and equipment to inspect rims, including visual inspection, calipers, and micrometers.

2. Repairing rims

Rim Technicians must be able to repair rims using a variety of techniques, such as welding, grinding, and straightening. They must also be able to apply new paint or powder coating to rims to restore their appearance.

3. Mounting and balancing tires

Rim Technicians must be able to mount and balance tires on rims. This involves using a tire mounting machine to install tires on rims, and then using a tire balancer to ensure that the tires are properly balanced.

4. Maintaining equipment

Rim Technicians must be able to maintain the equipment that they use, such as tire mounting machines, tire balancers, and welding equipment. This involves cleaning, lubricating, and adjusting equipment as needed.

Interview Tips

To prepare for an interview for a Rim Technician position, you should:

1. Research the company and the position

Before your interview, take some time to research the company you are applying to and the position you are interviewing for. This will help you to answer questions about the company and the position in a way that shows that you are interested and prepared.

2. Practice answering common interview questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “What are your strengths and weaknesses?”. It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

3. Highlight your relevant skills and experience

In your interview, be sure to highlight the skills and experience that are most relevant to the position you are interviewing for. For example, if you have experience repairing rims, be sure to mention that in your interview.

4. Be prepared to talk about your safety record

Rim Technicians work in a potentially hazardous environment, so it is important to have a good safety record. In your interview, be prepared to talk about your safety record and how you have prevented accidents in the past.

Next Step:

Now that you’re armed with the knowledge of Rim Technician interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Rim Technician positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini