Are you gearing up for an interview for a Spring Manufacturing Set-Up Technician position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Spring Manufacturing Set-Up Technician and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

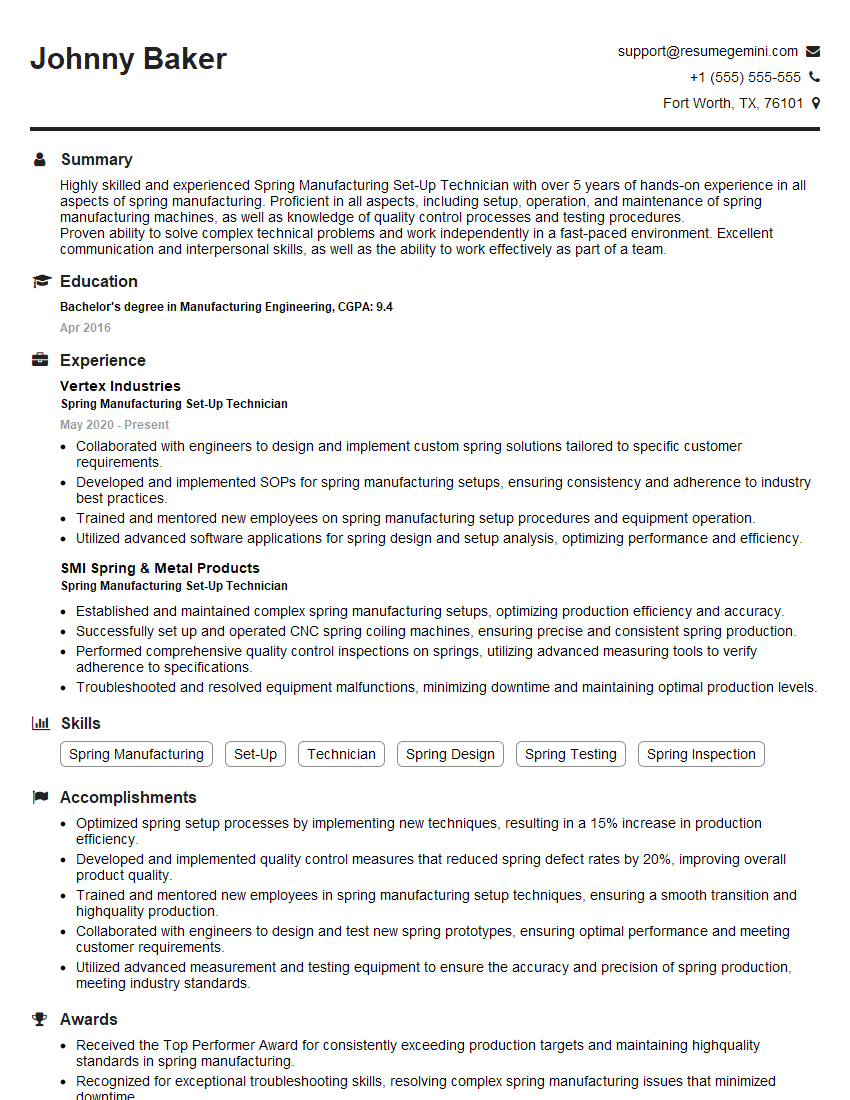

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Spring Manufacturing Set-Up Technician

Interview Questions for Spring Manufacturing Set-Up Technician

1. Describe the key responsibilities of a Spring Manufacturing Set-Up Technician?

As a Spring Manufacturing Set-Up Technician, I am responsible for:

- Setting up and maintaining spring manufacturing equipment, including coiling machines, heat treatment furnaces, and testing equipment.

- Developing and implementing production processes to ensure the efficient and accurate manufacture of springs.

- Troubleshooting and resolving manufacturing issues to minimize downtime and maintain production schedules.

- Inspecting springs to ensure they meet quality standards and specifications.

- Maintaining a clean and organized work area to ensure safety and efficiency.

2. What are the different types of springs that you have worked with?

I have worked with various types of springs, including:

- Compression springs

- Extension springs

- Torsion springs

- Belleville springs

- Conical springs

3. What are the key factors to consider when setting up a spring coiling machine?

When setting up a spring coiling machine, I consider the following factors:

- Spring diameter

- Spring length

- Spring material

- Spring pitch

- Number of coils

- Machine speed

4. How do you ensure the accuracy of spring dimensions during production?

To ensure the accuracy of spring dimensions during production, I take the following steps:

- Calibrate the coiling machine regularly.

- Use precision measuring equipment to inspect springs in-process.

- Implement statistical process control techniques to monitor and maintain accuracy.

5. What is the importance of heat treatment in spring manufacturing?

Heat treatment is a critical process in spring manufacturing because it enhances the properties of the spring, including:

- Strength

- Durability

- Fatigue resistance

- Corrosion resistance

6. What are the different types of heat treatment processes used for springs?

The common heat treatment processes used for springs include:

- Annealing

- Hardening

- Tempering

7. How do you inspect springs for quality and performance?

I inspect springs for quality and performance using the following techniques:

- Visual inspection

- Dimensional measurement

- Load testing

- Fatigue testing

8. What are the common manufacturing defects found in springs?

Common manufacturing defects found in springs include:

- Coil breaks

- Surface imperfections

- Dimensional variation

- Material defects

9. How do you troubleshoot and resolve manufacturing issues in spring production?

To troubleshoot and resolve manufacturing issues in spring production, I follow these steps:

- Identify the problem and its potential causes.

- Analyze the machine settings, material properties, and production environment.

- Implement corrective actions based on the identified root cause.

- Monitor the results and make adjustments as needed.

10. What is your experience with process improvement in spring manufacturing?

I have been actively involved in process improvement initiatives in spring manufacturing, including:

- Lean manufacturing techniques

- Statistical process control

- Kaizen events

- Equipment upgrades and automation

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Spring Manufacturing Set-Up Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Spring Manufacturing Set-Up Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Spring Manufacturing Set-Up Technicians play a crucial role in setting up and maintaining sophisticated spring manufacturing equipment. Their primary responsibilities include:

1. Machine Set-Up and Calibration

Set up, calibrate, and troubleshoot a variety of spring manufacturing machines, including coilers, grinders, and heat treatment equipment.

- Ensure machines meet specifications and tolerances.

- Identify and resolve production issues.

2. Tool and Fixture Development

Design, develop, and maintain tools and fixtures to improve production efficiency and product quality.

- Analyze production processes to identify areas for improvement.

- Collaborate with engineers and production teams.

3. Process Optimization

Continuously monitor and improve manufacturing processes to increase productivity and reduce waste.

- Implement lean manufacturing techniques.

- Troubleshoot and resolve quality issues.

4. Equipment Maintenance

Perform routine maintenance and repairs on spring manufacturing equipment to prevent breakdowns and ensure optimal performance.

- Lubricate, clean, and adjust equipment.

- Identify and replace worn or damaged parts.

Interview Tips

To ace an interview for a Spring Manufacturing Set-Up Technician position, consider the following tips:

1. Research the Company and Role

Thoroughly research the company’s history, products, and industry standing. Understanding the job requirements will enable you to tailor your responses and demonstrate your knowledge.

- Visit the company website and LinkedIn page.

- Read industry news and articles.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills, such as machine set-up, tool development, and process optimization. Share specific examples of how you have improved efficiency or solved production issues.

- Use the STAR method (Situation, Task, Action, Result) to describe your accomplishments.

- Quantify your results whenever possible.

3. Demonstrate a Commitment to Quality

Spring Manufacturing Set-Up Technicians are responsible for ensuring product quality. Highlight your attention to detail and your ability to meet or exceed specifications.

- Discuss your experience with quality control procedures.

- Explain how you handle production errors and implement corrective actions.

4. Show Passion for the Industry

Interviewers want to see candidates who are genuinely interested in spring manufacturing. Express your enthusiasm for the industry and your desire to learn and grow in the field.

- Share your knowledge of spring manufacturing techniques and trends.

- Discuss your interest in staying up-to-date with industry advancements.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Spring Manufacturing Set-Up Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!