Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Spring Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

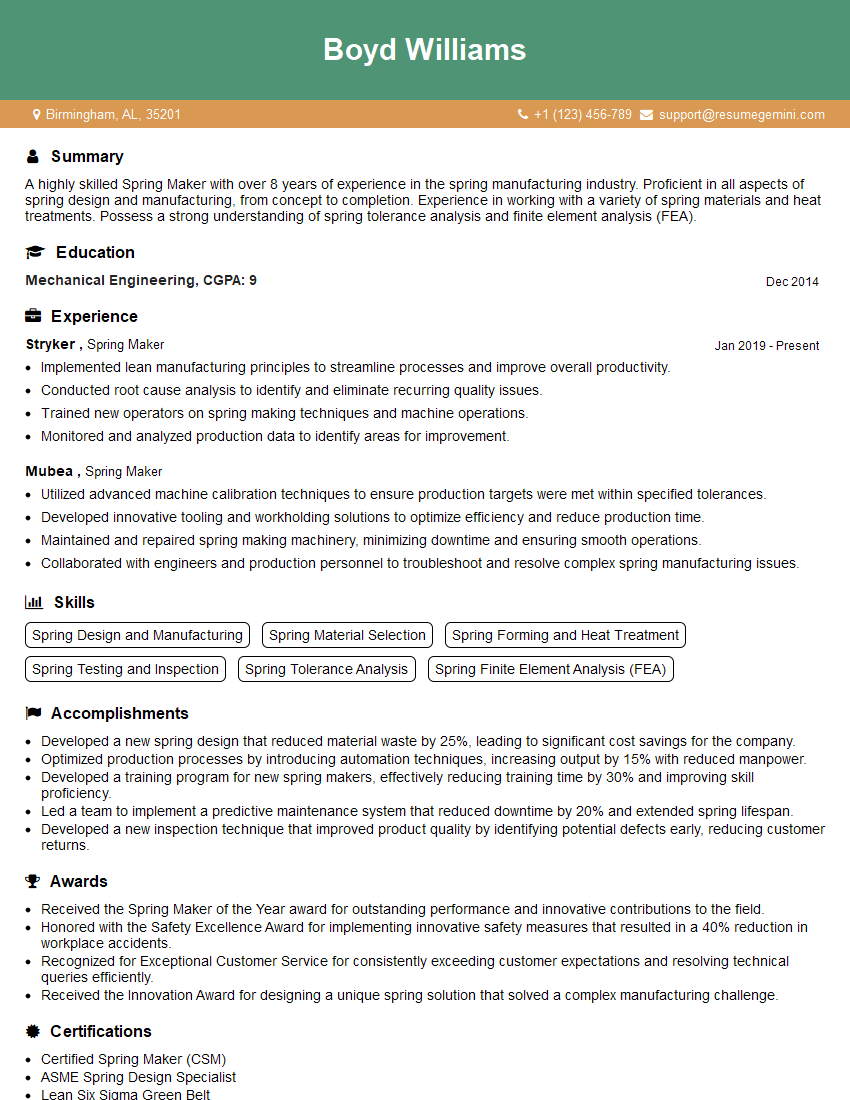

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Spring Maker

1. What are the key responsibilities of a Spring Maker?

- Design and develop springs using various materials and techniques

- Operate and maintain spring-making machinery

- Inspect and test springs to ensure quality and performance

- Troubleshoot and resolve production issues

- Follow safety protocols and maintain a clean and organized work environment

2. What types of springs have you worked with?

Compression Springs

- Round wire compression springs

- Conical compression springs

Tension Springs

- Round wire tension springs

- Extension springs

3. What is the difference between cold-forming and hot-forming springs?

- Cold-forming: Springs are formed at room temperature, resulting in higher precision and surface finish

- Hot-forming: Springs are formed at elevated temperatures, allowing for larger deformations and producing springs with higher strength and wear resistance

4. What are the different types of spring materials?

- Steel: Commonly used for its strength and durability

- Stainless steel: Resistant to corrosion and oxidation

- Phosphor bronze: Has good electrical conductivity and low friction

- Beryllium copper: High strength and electrical conductivity

5. What are the essential tools and equipment used in spring making?

- Spring coilers

- Wire feeders

- Torsion testers

- Hardness testers

- Magnifiers and microscopes

6. What are the common defects that can occur in spring manufacturing?

- Torsional defects (e.g., uneven tension, kinking)

- Dimensional defects (e.g., incorrect size or shape)

- Material defects (e.g., cracks, inclusions)

- Surface defects (e.g., pitting, corrosion)

7. What quality control measures are implemented in spring manufacturing?

- Incoming material inspection

- In-process inspections (e.g., dimensional checks, torsion testing)

- Final inspection (e.g., visual inspection, performance testing)

- Statistical process control (SPC) techniques

8. What is the importance of heat treatment in spring manufacturing?

- Improves the mechanical properties of the spring, such as strength and toughness

- Reduces internal stresses and increases stability

- Enhances the spring’s durability and wear resistance

9. What is the role of spring design software in the spring making process?

- Optimizes spring design based on specified requirements

- Simulates spring behavior and predicts performance

- Generates detailed manufacturing instructions

- Reduces design time and improves accuracy

10. How do you stay up-to-date with the latest advancements in spring making technology?

- Attend industry conferences and workshops

- Read technical journals and research papers

- Network with other spring makers and experts

- Participate in industry training programs

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Spring Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Spring Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Spring Makers, also known as Spring Coilers, are responsible for producing and maintaining springs used in a wide range of industries, including automotive, aerospace, and electronics. Their primary duties involve operating and maintaining spring-making machines, ensuring the quality of springs produced, and adhering to safety protocols.

1. Spring Production

Spring Makers are responsible for setting up and operating spring-making machines to produce springs according to specified designs and specifications. They adjust machine settings, load raw materials, and monitor the production process to ensure it runs smoothly and efficiently.

- Set up and operate spring-making machines

- Adjust machine settings to produce springs with the desired dimensions and properties

- Load raw materials, such as wire coils, into the machines

- Monitor the production process and make adjustments as needed to ensure quality and efficiency

2. Quality Control

Spring Makers are responsible for inspecting and testing springs to ensure they meet the required specifications and standards. They use measuring tools, gauges, and other equipment to verify the dimensions, shape, and performance of the springs.

- Inspect springs for defects, such as cracks, burrs, or deformations

- Measure springs to ensure they meet the specified dimensions and tolerances

- Test springs to determine their performance, such as spring rate and load capacity

- Maintain records of inspection and testing results

3. Machine Maintenance

Spring Makers are responsible for maintaining spring-making machines in good working condition. They perform routine maintenance tasks, such as cleaning, lubrication, and adjustment, to prevent breakdowns and ensure optimal performance.

- Clean and lubricate machines regularly

- Adjust and calibrate machines to ensure accuracy and precision

- Troubleshoot and repair minor machine malfunctions

- Report major machine issues to supervisors for further assistance

4. Safety Compliance

Spring Makers work in a manufacturing environment that involves potential hazards, such as heavy machinery and sharp objects. They are responsible for following safety protocols and wearing appropriate personal protective equipment (PPE) to minimize the risk of accidents and injuries.

- Follow established safety protocols and procedures

- Wear appropriate PPE, such as safety glasses, gloves, and earplugs

- Operate machines safely and avoid dangerous practices

- Report any safety hazards or concerns to supervisors immediately

Interview Tips

Preparing for an interview for a Spring Maker position requires a combination of technical knowledge and an understanding of the industry. Here are some tips to help candidates ace their interviews:

1. Research the Company and Industry

Before the interview, candidates should thoroughly research the company and the industry to gain a good understanding of their operations, products, and the overall market landscape. This knowledge will help them demonstrate their interest in the position and show that they are informed about the company’s business.

- Visit the company’s website to learn about their products, services, and history

- Read industry publications and articles to stay updated on the latest trends and technologies

- Connect with the company on social media to follow their announcements and updates

2. Practice Common Interview Questions

Candidates can prepare for common interview questions by practicing their answers beforehand. This will help them feel more confident and articulate during the interview. Some common questions that they may encounter include:

- Tell me about your experience in spring making

- What are your strengths and weaknesses as a Spring Maker?

- How do you handle working under pressure and deadlines?

3. Prepare Questions for the Interviewer

Asking well-thought-out questions at the end of the interview demonstrates interest and engagement. Candidates should prepare a few questions that they would like to ask the interviewer about the role, the company, or the industry.

- What are the current challenges facing the spring making industry?

- What are the company’s growth plans for the future?

- What opportunities for professional development are available to employees?

4. Dress Professionally and Arrive on Time

First impressions matter, so candidates should dress professionally and arrive on time for their interview. This shows respect for the interviewer and the company, and it can make a positive impact on their chances of making a good impression.

- Wear business casual attire, such as a button-down shirt and slacks

- Arrive at the interview location at least 15 minutes early to allow for any unexpected delays

- Be polite and respectful to everyone you encounter, including the receptionist and other employees

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Spring Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!