Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Tool Machine Setup Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Tool Machine Setup Operator so you can tailor your answers to impress potential employers.

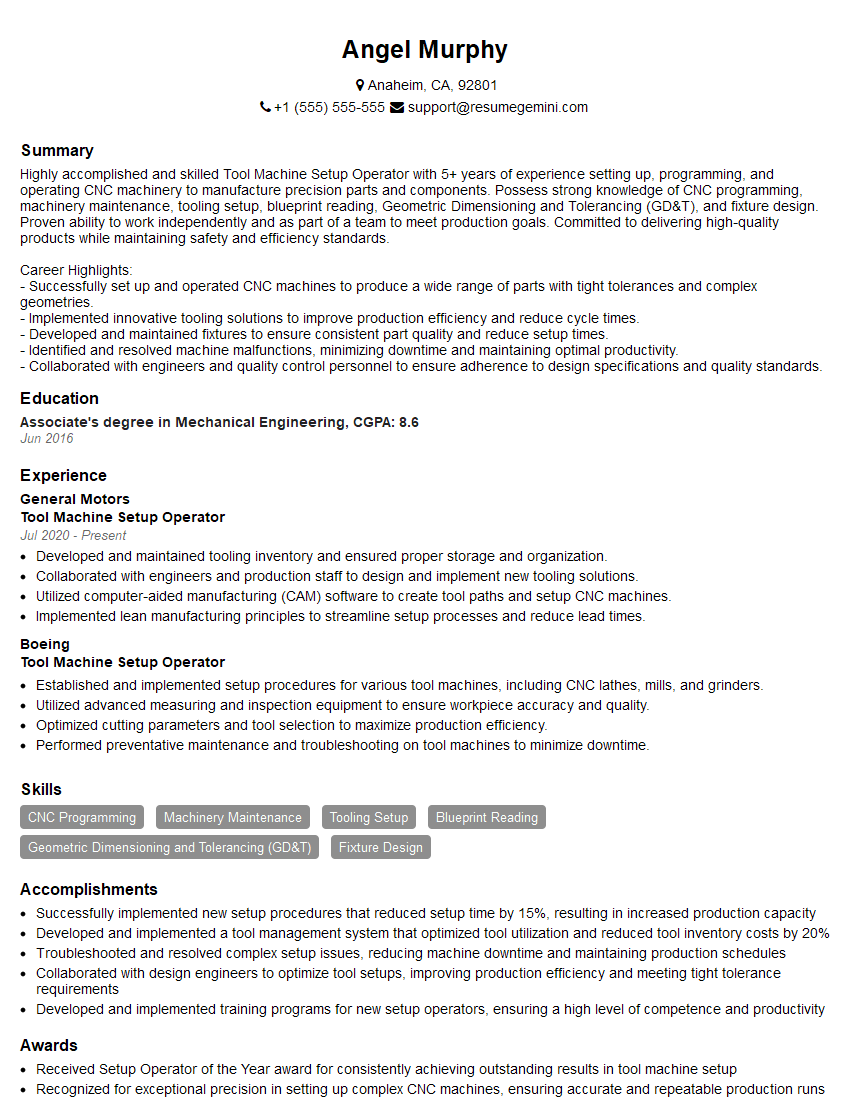

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tool Machine Setup Operator

1. What are the essential steps involved in setting up a CNC machine?

The essential steps involved in setting up a CNC machine are:

- Loading the CNC program into the machine’s controller.

- Installing the workpiece and fixturing.

- Setting the machine’s coordinate system and offsets.

- Running a trial cut to verify the program and setup.

- Making any necessary adjustments to the program or setup.

- Starting the production run.

2. How do you ensure the accuracy of your setups?

I ensure the accuracy of my setups by following a proven procedure and using precision measuring tools.

-

Using precision tools

- Dial indicators

- Micrometers

- Calipers

- Laser measurement systems

-

Following a proven procedure

- Establishing a coordinate system

- Setting offsets and tool lengths

- Running trial cuts and making adjustments

- Verifying the accuracy of the setup

3. What are the most common problems you encounter during setup and how do you troubleshoot them?

The most common problems I encounter during setup and how I troubleshoot them are:

-

Tool breakage

- Check the tool for damage.

- Check the toolholder for proper tightening.

- Check the spindle speed and feed rate.

- Check the workpiece material and hardness.

-

Workpiece misalignment

- Check the fixturing for proper alignment.

- Check the coordinate system and offsets.

- Check the workpiece for distortion.

-

Program errors

- Check the program for syntax errors.

- Check the program for logic errors.

- Run a simulation of the program.

4. What are the different types of cutting tools used in CNC machining?

The different types of cutting tools used in CNC machining include:

-

End mills

- Used for milling operations

- Variety of shapes and sizes available

-

Drills

- Used for drilling holes

- Variety of sizes and types available

-

Taps

- Used for threading holes

- Variety of sizes and thread types available

-

Boring bars

- Used for boring holes

- Variety of sizes and shapes available

-

Reamer

- Used to improve the finish of holes

- Variety of sizes and types available

5. How do you select the appropriate cutting tool for a given application?

I select the appropriate cutting tool for a given application by considering the following factors:

- The type of material being machined

- The desired surface finish

- The required accuracy and tolerance

- The machine tool being used

- The cutting tool’s availability and cost

6. What are the safety precautions that must be followed when operating a CNC machine?

The safety precautions that must be followed when operating a CNC machine include:

- Wear appropriate safety gear, including safety glasses, gloves, and earplugs.

- Keep the work area clean and free of debris.

- Never operate a CNC machine if you are under the influence of alcohol or drugs.

- Never reach into the cutting area while the machine is running.

- Always follow the manufacturer’s operating instructions.

7. What is your experience with different types of CNC machines?

I have experience with a variety of different types of CNC machines, including:

- 3-axis CNC milling machines

- 4-axis CNC milling machines

- 5-axis CNC milling machines

- CNC turning machines

- CNC Swiss lathes

8. What is your experience with programming CNC machines?

I have experience programming CNC machines using a variety of software programs, including:

- Mastercam

- Solidworks

- Siemens NX

- Heidenhain iTNC

- Fanuc

9. What is your experience with setting up and operating CNC machines?

I have experience setting up and operating CNC machines for a variety of different applications, including:

- Part production

- Prototype development

- Tool and die making

- Aerospace manufacturing

- Medical device manufacturing

10. What are your strengths and weaknesses as a CNC machine operator?

My strengths as a CNC machine operator include:

- Strong attention to detail

- Excellent problem-solving skills

- Ability to work independently

- Experience with a variety of CNC machines and software programs

My weaknesses as a CNC machine operator include:

- Limited experience with some of the more advanced CNC machines

- I am still learning some of the more complex programming techniques

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tool Machine Setup Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tool Machine Setup Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tool Machine Setup Operators play a critical role in manufacturing operations, ensuring the efficient and precise operation of equipment.

1. Machine Setup and Calibration

Setup and calibrate tool machines according to blueprints and specifications.

- Adjust and maintain tools, fixtures, and cutting parameters.

- Load and unload raw materials and finished products.

2. Quality Control and Inspection

Monitor production processes, inspect finished products, and identify defects.

- Measure and inspect parts to ensure adherence to quality standards.

- Implement corrective actions to eliminate errors and maintain product quality.

3. Equipment Maintenance

Perform preventative maintenance tasks and troubleshoot equipment issues.

- Lubricate and clean machines.

- Diagnose and repair minor equipment malfunctions.

4. Safety Compliance

Adhere to safety protocols and maintain a clean and organized work environment.

- Wear appropriate safety gear.

- Follow emergency evacuation procedures.

Interview Tips

Preparing for a Tool Machine Setup Operator interview requires a combination of technical knowledge, problem-solving skills, and a strong attention to detail. Here are some effective tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and industry trends. Research their use of tool machines and any specific requirements or certifications they may have.

- Visit the company website, LinkedIn page, and industry news sources.

- Read trade publications and attend industry events.

2. Highlight Your Technical Skills

Emphasize your proficiency in operating and calibrating tool machines, including your knowledge of different types of equipment, cutting tools, and materials.

- Provide examples of specific machines or processes you have experience with.

- Quantify your results whenever possible, such as improving production efficiency or reducing scrap rates.

3. Showcase Your Problem-Solving Abilities

Describe situations where you identified and resolved problems with tool machines or production processes. Highlight your logical thinking, analytical skills, and attention to detail.

- Use the STAR method (Situation, Task, Action, Result) to structure your responses.

- Be specific about the steps you took, the challenges you faced, and the outcomes you achieved.

4. Demonstrate Your Safety Awareness

Emphasize your commitment to safety in the workplace. Describe your understanding of safety protocols, machine guarding, and proper handling of tools and materials.

- Mention any safety certifications or training you have received.

- Share examples of how you have proactively identified and mitigated safety risks.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Tool Machine Setup Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Tool Machine Setup Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.