Feeling lost in a sea of interview questions? Landed that dream interview for Die Maker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Die Maker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

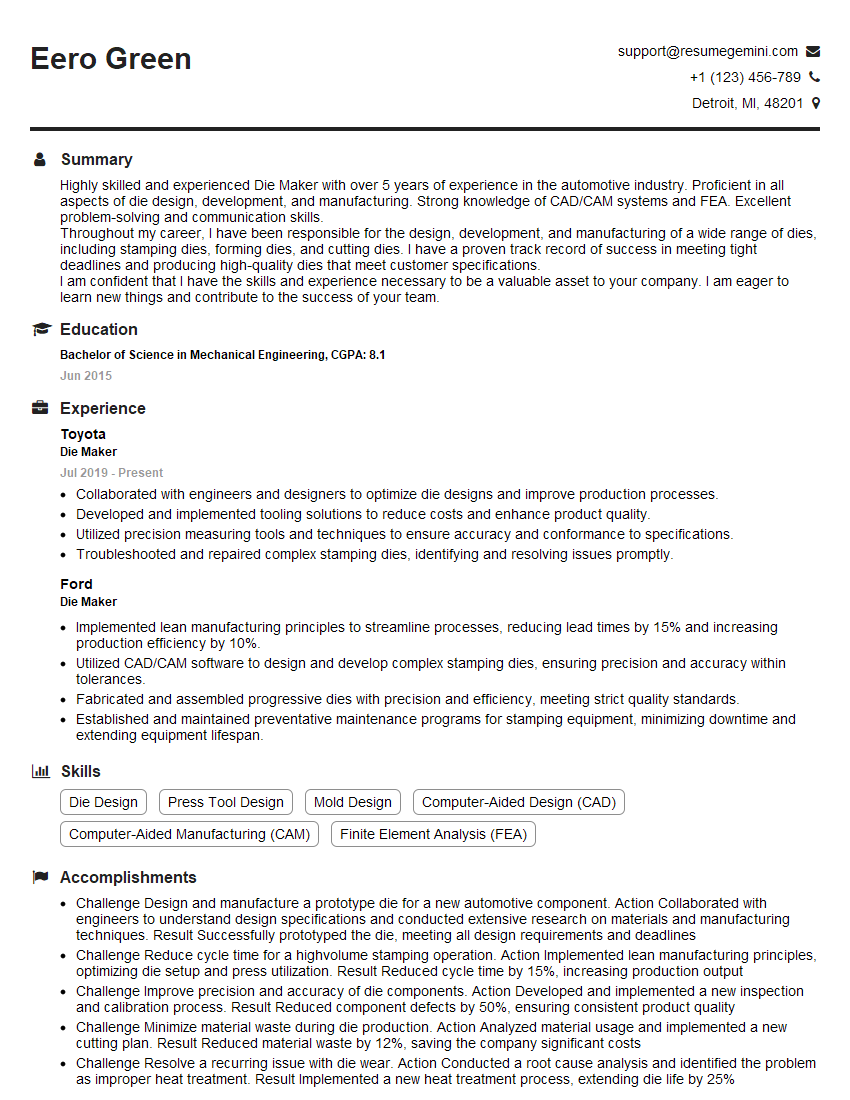

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Die Maker

1. What are the different types of die presses, and what are their advantages and disadvantages?

- Mechanical presses: These presses use a flywheel and a clutch to generate force. They are relatively inexpensive and easy to operate, but they are also noisy and can produce vibrations.

- Hydraulic presses: These presses use hydraulic fluid to generate force. They are more expensive than mechanical presses, but they are also quieter and produce less vibration.

- Pneumatic presses: These presses use compressed air to generate force. They are the most expensive type of press, but they are also the quietest and produce the least vibration.

2. What are the different types of die materials, and what are their properties?

Tool steels

- High-carbon steel: This is the most common type of die steel. It is hard and wear-resistant, but it is also brittle.

- Alloy steel: This type of steel is alloyed with other elements, such as chromium, molybdenum, and vanadium. It is harder and more wear-resistant than high-carbon steel, but it is also more expensive.

Carbide

- Tungsten carbide: This is a very hard and wear-resistant material. It is often used for dies that are used to cut or form hard materials.

- Titanium carbide: This material is even harder and more wear-resistant than tungsten carbide. It is often used for dies that are used to cut or form very hard materials.

Ceramics

- Alumina: This is a very hard and wear-resistant material. It is often used for dies that are used to cut or form metals.

- Zirconia: This material is even harder and more wear-resistant than alumina. It is often used for dies that are used to cut or form very hard metals.

3. What are the different types of die manufacturing processes?

- EDM (Electrical Discharge Machining): This process uses electrical sparks to erode material from the die. It is used to create complex shapes and intricate details.

- Wire EDM: This process uses a thin wire to cut through the die material. It is used to create very precise and accurate shapes.

- Laser cutting: This process uses a laser to cut through the die material. It is used to create complex shapes and intricate details.

- Waterjet cutting: This process uses a high-pressure water jet to cut through the die material. It is used to create complex shapes and intricate details.

4. What are the different types of die maintenance procedures?

- Preventive maintenance: This type of maintenance is performed on a regular schedule to prevent problems from occurring. It includes tasks such as cleaning, lubrication, and inspection.

- Corrective maintenance: This type of maintenance is performed to fix problems that have already occurred. It includes tasks such as repairing or replacing damaged parts.

- Predictive maintenance: This type of maintenance uses monitoring devices to predict when problems are likely to occur. It allows maintenance to be performed before problems actually happen.

5. What are the different types of die testing procedures?

- Visual inspection: This type of inspection is used to look for defects in the die. It is performed using a magnifying glass or a microscope.

- Dimensional inspection: This type of inspection is used to measure the dimensions of the die. It is performed using a micrometer or a coordinate measuring machine (CMM).

- Functional testing: This type of testing is used to test the performance of the die. It is performed by running the die through a production cycle.

6. What are the different types of die safety procedures?

- Lockout/tagout: This procedure is used to prevent machinery from being started up while maintenance is being performed.

- Machine guarding: This procedure is used to protect workers from being injured by machinery.

- Personal protective equipment (PPE): This procedure is used to protect workers from being injured by flying debris or other hazards.

7. What are the different types of die troubleshooting procedures?

- Problem identification: This step involves identifying the problem that is causing the die to malfunction.

- Root cause analysis: This step involves determining the underlying cause of the problem.

- Solution implementation: This step involves implementing a solution to the problem.

- Verification: This step involves verifying that the solution has fixed the problem.

8. What are the different types of die repair procedures?

- Welding: This procedure is used to repair cracks or breaks in the die.

- Brazing: This procedure is used to join two or more pieces of metal together.

- Soldering: This procedure is used to join two or more pieces of metal together using a solder alloy.

- Machining: This procedure is used to remove material from the die to repair damaged areas.

9. What are the different types of die storage procedures?

- Proper storage: Dies should be stored in a cool, dry place. They should be protected from moisture and dust.

- Coating: Dies can be coated with a protective coating to prevent corrosion.

- Packaging: Dies can be packaged in boxes or crates to protect them from damage.

10. What are the different types of die handling procedures?

- Manual handling: Dies can be lifted and moved manually. However, it is important to use proper lifting techniques to avoid injury.

- Mechanical handling: Dies can be lifted and moved using a crane or forklift.

- Automated handling: Dies can be lifted and moved using an automated system.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Die Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Die Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Die Maker

Die Makers are responsible for the creation and maintenance of dies, which are used in metalworking to shape and cut materials. Their key responsibilities include:

1. Die Design and Development

Collaborate with engineers to design and develop new dies or modify existing ones.

- Analyze blueprints and specifications to determine die requirements.

- Use computer-aided design (CAD) software to create 3D models and technical drawings.

2. Die Manufacturing

Build and assemble dies using various machining techniques and hand tools.

- Operate CNC machines, lathes, and other equipment to cut and shape metal components.

- Weld, braze, or solder components together to create the final die.

3. Die Repair and Maintenance

Maintain and repair dies to ensure optimal performance.

- Inspect dies for wear and damage.

- Perform routine maintenance tasks, such as cleaning, lubrication, and sharpening.

- Troubleshoot and resolve die malfunctions.

4. Process Improvement

Identify and implement ways to improve die design, manufacturing, and maintenance processes.

- Analyze production data and identify areas for improvement.

- Suggest modifications to die designs or manufacturing techniques to enhance efficiency.

Interview Tips for Die Makers

To prepare for a Die Maker interview, candidates should focus on demonstrating their technical skills, experience, and problem-solving abilities. Here are some tips:

1. Research the Company and Position

Thoroughly research the company and the specific job you’re applying for. This will help you understand their products, industry, and the specific responsibilities of the Die Maker role.

- Visit the company website, read industry articles, and connect with employees on LinkedIn.

- Identify the key requirements listed in the job description and match your qualifications accordingly.

2. Highlight Your Technical Skills

Emphasize your proficiency in die design, manufacturing, and maintenance. Provide specific examples of your work and the results you achieved.

- Describe your experience with CAD software, CNC machines, and other relevant equipment.

- Quantify your accomplishments, such as the number of dies you designed, built, or repaired, and the impact on production efficiency.

3. Demonstrate Problem-Solving Abilities

Die Makers often encounter unexpected challenges. Highlight your ability to solve problems, identify root causes, and implement effective solutions.

- Describe an instance where you troubleshoot a die malfunction and resolved it successfully.

- Explain how you identify areas for process improvement and implement changes to enhance efficiency.

4. Prepare for Technical Questions

Expect technical questions related to die design, manufacturing, and maintenance. Practice answering these questions clearly and concisely, using specific examples to illustrate your knowledge and skills.

- Study common die design principles, such as die clearance, cutting forces, and material properties.

- Review different types of CNC machines, machining techniques, and welding processes.

5. Practice Your Communication Skills

Effective communication is crucial for Die Makers. Ensure you can articulate your ideas, technical concepts, and solutions clearly to both technical and non-technical audiences.

- Practice answering interview questions out loud to improve your delivery and clarity.

- Prepare questions to ask the interviewer that demonstrate your interest and engagement in the role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Die Maker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.