Are you gearing up for a career in Die Try Out Worker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Die Try Out Worker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

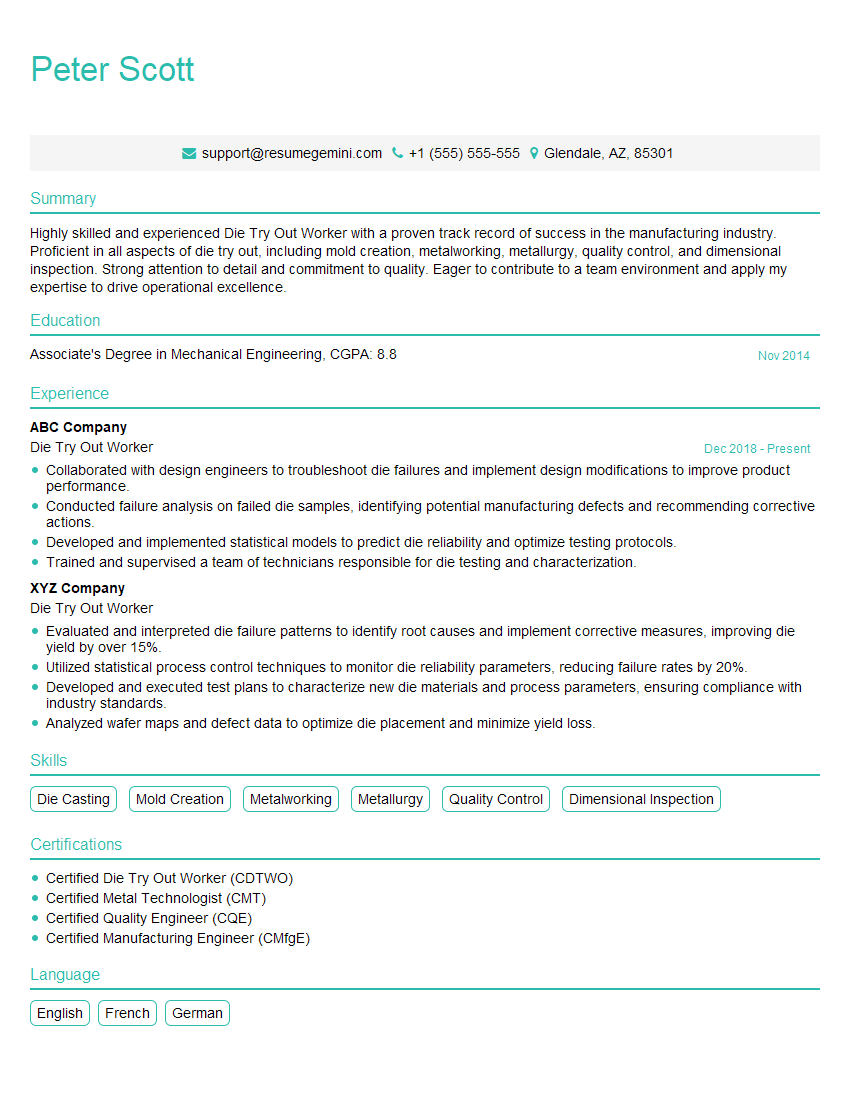

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Die Try Out Worker

1. What are the different types of die tryout presses and their applications?

There are various types of die tryout presses with specific applications. Here are some common types:

- Mechanical Tryout Presses: These presses utilize a mechanical system, typically a flywheel and clutch mechanism, to generate force. They are suitable for low- to medium-volume tryout operations.

- Hydraulic Tryout Presses: These presses rely on hydraulic fluid to transmit force. They offer precise control over pressure and speed, making them ideal for intricate and delicate tryout operations.

- Servo Tryout Presses: These presses combine hydraulics with advanced servo technology. They provide high precision, speed, and repeatability, enabling manufacturers to simulate production conditions accurately.

2. Explain the principles of die tryout.

Die Alignment

- Ensuring proper alignment of the die components to achieve optimal forming.

- Using alignment pins, dowels, or other precision tools to position the die precisely.

Tryout Parameters

- Determining appropriate tryout parameters such as pressure, speed, and dwell time.

- Adjusting these parameters to optimize forming and prevent damage to the die or workpiece.

Part Evaluation

- Inspecting the formed parts for dimensional accuracy, surface finish, and any defects.

- Analyzing part characteristics to make necessary adjustments to the die or process.

3. Describe the various measuring instruments used in die tryout.

Die tryout relies on precise measurements to ensure accurate forming. Common measuring instruments include:

- Dial Indicators: These gauges measure small linear displacements and are used to verify die alignment and clearances.

- Micrometers: Precision measuring tools used to measure dimensions, such as part thickness or die clearances.

- Calipers: Versatile measuring tools for measuring internal and external dimensions, depths, and more.

- Coordinate Measuring Machines (CMMs): Advanced measuring systems that provide comprehensive data on part geometry and dimensions.

4. What are the common problems encountered during die tryout and how do you troubleshoot them?

Die tryout can encounter various problems, including:

- Alignment Issues: Misalignment of die components can lead to poor forming. Troubleshooting involves checking alignment pins, dowels, and the press itself.

- Clearance Issues: Insufficient clearance between die components can cause jamming or damage. Adjustments to clearances or modifications to the die may be necessary.

- Wear and Tear: Die components can wear over time, affecting performance. Regular maintenance and replacement of worn parts are crucial.

- Material Defects: Faulty material can lead to poor forming. Inspecting the material and adjusting process parameters may be necessary.

5. How do you ensure safety during die tryout operations?

Safety is paramount during die tryout. Here are crucial safety measures:

- Proper Training: Operators should receive comprehensive training on die tryout procedures and safety protocols.

- Machine Guarding: Press guards and other machine safeguards must be in place and operational.

- Personal Protective Equipment (PPE): Operators should wear appropriate PPE, including gloves, safety glasses, and ear protection.

- Die Inspection: Conduct thorough inspections of the die before use to identify any potential hazards.

6. Describe your experience with die polishing and its importance in die tryout.

Die polishing involves smoothing and refining the surfaces of die components to reduce friction, improve surface finish, and extend die life.

- Benefits: Improved part quality, reduced surface defects, increased die life.

- Techniques: Various polishing techniques are used, such as manual polishing, mechanical polishing, or electrochemical polishing.

- Importance in Die Tryout: Ensures smooth part flow, prevents material sticking, and prolongs die lifespan.

7. What is the role of die tryout in the overall stamping process?

Die tryout plays a critical role in stamping by:

- Optimizing Die Performance: Verifying die alignment, clearances, and forming accuracy, ensuring efficient and defect-free production.

- Process Validation: Establishing optimal process parameters, including pressure, speed, and lubrication, to maximize part quality and productivity.

- Troubleshooting: Identifying and resolving issues during die tryout allows for early detection and correction of potential problems during actual production.

8. Explain your understanding of die clearance and how it affects the stamping process.

Die clearance refers to the gap between the punch and die surfaces during metal forming.

- Effects on Material Flow: Adequate clearance allows material to flow smoothly, reducing friction and improving part quality.

- Influence on Part Dimensions: Clearance directly impacts part thickness and dimensional accuracy. Proper clearance is crucial for meeting specifications.

- Die Life and Maintenance: Excessive clearance can accelerate die wear, while insufficient clearance can lead to material jamming. Optimizing clearance prolongs die life.

9. Describe your experience in using die tryout software.

Explain your familiarity with die tryout software and its applications.

- Simulation and Optimization: Using software to simulate die tryout processes, optimize parameters, and identify potential issues before physical tryout.

- Data Analysis: Utilizing software to analyze tryout data, such as pressure curves and part dimensions, to improve process understanding and accuracy.

- User Interface: Describe your comfort level with the software’s user interface, data input, and visualization capabilities.

10. How do you stay up-to-date with the latest advancements in die tryout techniques and technologies?

Explain your commitment to continuous learning and staying abreast of new developments.

- Industry Events and Conferences: Attending industry events and conferences to network with experts, learn about new technologies, and enhance knowledge.

- Technical Publications and Webinars: Reading industry publications and participating in webinars to stay informed about advancements in die tryout practices.

- Training and Certification: Pursuing additional training or certifications to expand skills and demonstrate commitment to professional development.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Die Try Out Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Die Try Out Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Die Try Out Workers are skilled individuals responsible for operating die casting machines and ensuring the production of high-quality castings. Their key job responsibilities include:

1. Die Setup and Operation

Setting up and operating die casting machines following established procedures and specifications.

- Preparing and installing dies into the machine.

- Adjusting machine settings, such as temperature and pressure, to optimize casting quality.

2. Casting Production

Monitoring the casting process, including metal pouring, ejection, and cooling.

- Ensuring castings meet quality standards through visual inspection and dimension checks.

- Identifying and resolving any casting defects or machine malfunctions.

3. Process Improvement

Participating in continuous improvement initiatives to enhance productivity and quality.

- Analyzing casting defects and implementing corrective actions.

- Suggesting process improvements based on observations and experience.

4. Safety Compliance

Adhering to all safety regulations and procedures in the workplace.

- Wearing appropriate personal protective equipment.

- Maintaining a clean and organized work area.

Interview Tips

To ace the interview for a Die Try Out Worker position, candidates should consider the following tips:

1. Knowledge of Die Casting Process

Demonstrate a strong understanding of the die casting process, including different types of machines, materials, and defects.

- Review technical articles or books on die casting.

- Prepare examples of your experience in setting up and operating die casting machines.

2. Quality Control Experience

Highlight your experience in quality control and your ability to identify and resolve casting defects.

- Emphasize your knowledge of quality standards and inspection techniques.

- Share examples of how you have improved casting quality in previous roles.

3. Problem-Solving Skills

Showcase your problem-solving abilities and your approach to resolving machine malfunctions and casting defects.

- Prepare examples of challenges you have faced and how you overcame them.

- Explain your thought process and the steps you take to identify and solve problems.

4. Safety Awareness

Emphasize your commitment to safety and your knowledge of best practices in the metalworking industry.

- Highlight any safety training or certifications you have obtained.

- Explain your understanding of safety protocols and your role in maintaining a safe work environment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Die Try Out Worker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!