Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Die Trouble Shooter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

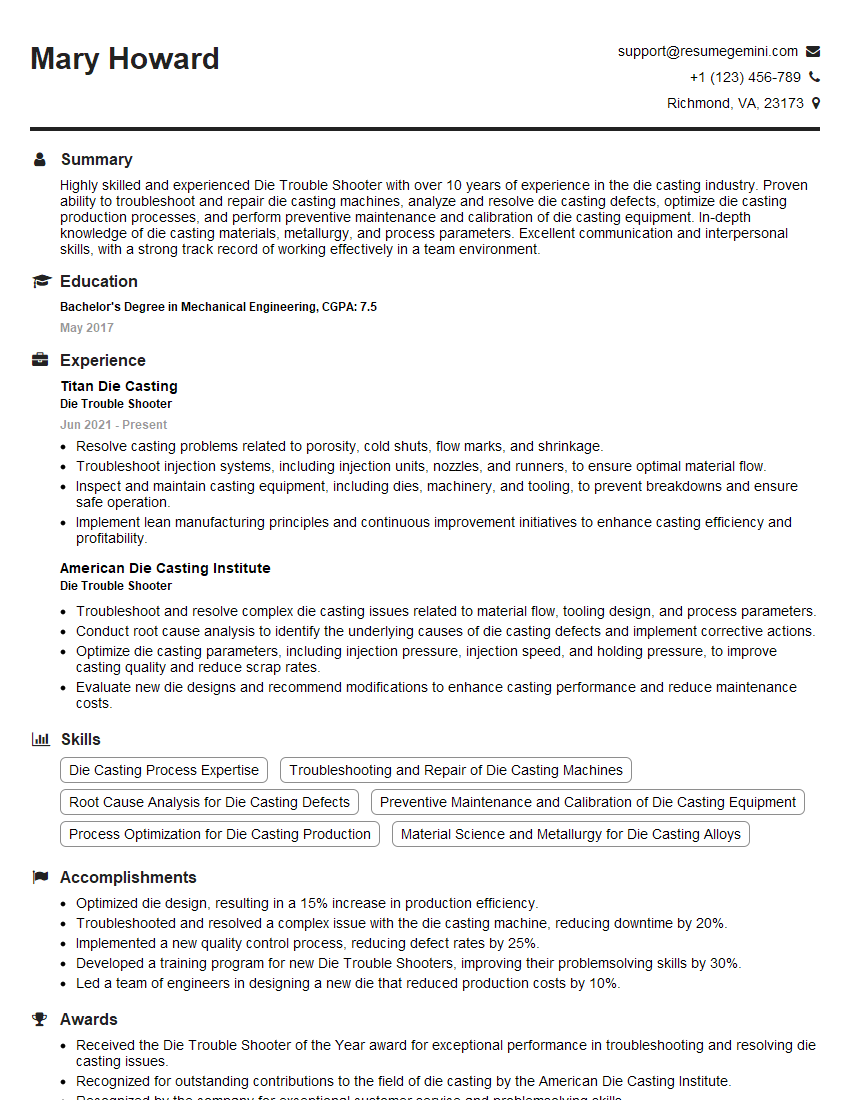

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Die Trouble Shooter

1. Describe your approach to troubleshooting die problems.

- Begin by identifying the problem symptoms and gathering relevant data.

- Conduct a thorough inspection of the die, equipment, and process parameters.

- Analyze the data and identify potential causes of the problem.

- Develop and implement corrective actions to resolve the issue and prevent recurrence.

- Document the troubleshooting process and findings for future reference.

2. How do you determine the root cause of a die problem?

Identify problem symptoms and gather data

- Observe the die in operation and note any unusual sounds, vibrations, or wear patterns.

- Collect data on process parameters such as temperature, pressure, and cycle time.

- Review maintenance records and production logs for any recent changes or events.

Analyze data and identify potential causes

- Use statistical techniques to identify correlations between process parameters and die problems.

- Consult with engineers, metallurgists, and other experts to gain insights.

- Consider multiple potential causes and develop hypotheses for testing.

Develop and implement corrective actions

- Design and conduct experiments to test hypotheses and isolate the root cause.

- Implement corrective actions based on the experimental results.

- Monitor the die performance to ensure the problem has been resolved.

3. Explain how you would troubleshoot a die that is producing parts with inconsistent dimensions.

- Check the die dimensions against the design specifications.

- Inspect the die for wear, damage, or misalignment.

- Measure the material thickness and hardness to ensure they are within tolerance.

- Check the press settings and ensure they are appropriate for the die and material.

- Observe the die in operation and look for any signs of deflection or vibration.

4. What are some of the common causes of die failure?

- Excessive wear and tear due to high production volumes.

- Improper maintenance, such as lack of lubrication or cleaning.

- Defects in the die material, such as cracks or inclusions.

- Misalignment of the die components.

- Overheating due to insufficient cooling or excessive friction.

5. How do you maintain and care for dies to extend their lifespan?

- Regularly clean and lubricate dies to prevent wear and tear.

- Inspect dies for damage or wear and make repairs as needed.

- Store dies in a controlled environment to prevent corrosion and damage.

- Follow the manufacturer’s recommended maintenance schedule.

- Train operators on proper die handling and maintenance techniques.

6. What software and equipment do you use for die troubleshooting?

- Computer-aided design (CAD) software for die design and analysis.

- Finite element analysis (FEA) software for simulating die performance.

- Metrology equipment for measuring die dimensions and surface finish.

- Non-destructive testing (NDT) equipment for detecting defects in dies.

- Optical microscopes for examining die surfaces and wear patterns.

7. How do you stay up-to-date on the latest die troubleshooting techniques?

- Attend industry conferences and workshops.

- Read technical journals and articles related to die troubleshooting.

- Participate in online forums and discussion groups.

- Consult with experts in the field.

- Conduct research and development to explore new troubleshooting methods.

8. What are some of the challenges you have faced as a die trouble shooter?

- Troubleshooting complex die problems with multiple potential causes.

- Working under tight deadlines and pressure to resolve production issues.

- Communicating effectively with engineers, operators, and other stakeholders.

- Staying up-to-date with the latest die troubleshooting techniques.

- Balancing the need to resolve problems quickly with the need to find permanent solutions.

9. How do you measure your success as a die trouble shooter?

- Reduced production downtime due to die problems.

- Improved die performance and part quality.

- Increased die lifespan and reduced maintenance costs.

- Positive feedback from engineers, operators, and management.

- Recognition for innovative troubleshooting solutions.

10. What are your career goals as a die trouble shooter?

- To become a leading expert in die troubleshooting.

- To develop new and innovative troubleshooting techniques.

- To mentor and train other die trouble shooters.

- To contribute to the advancement of the die troubleshooting field.

- To achieve a position of leadership and responsibility in the industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Die Trouble Shooter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Die Trouble Shooter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Die Trouble Shooter is responsible for identifying, analyzing, and resolving die-related issues that affect the production process. Key responsibilities include:

1. Troubleshooting and Die Maintenance

Investigate and diagnose die-related problems, such as die breakage, wear, and misalignment.

- Inspect and maintain dies, including cleaning, lubrication, and adjustment.

- Monitor die performance and recommend corrective actions to prevent future problems.

2. Problem Analysis and Resolution

Analyze die-related issues and develop solutions to improve production efficiency.

- Use analytical tools and techniques to identify root causes of die problems.

- Collaborate with engineers, technicians, and operators to implement solutions.

3. Process Improvement and Optimization

Initiate and implement process improvements to reduce die-related downtime and increase production yield.

- Identify and eliminate bottlenecks in the die-making and production processes.

- Evaluate new die technologies and materials to improve die performance.

4. Training and Support

Provide training and technical support to operators and other team members on die-related issues.

- Develop and deliver training programs on die maintenance, troubleshooting, and safety.

- Answer questions and provide guidance to operators to ensure proper die handling and operation.

Interview Tips

To ace an interview for a Die Trouble Shooter position, follow these tips:

1. Research the Company and Role

Familiarize yourself with the company’s industry, products, and the specific responsibilities of the Die Trouble Shooter role.

- Visit the company website and review job descriptions.

- Use LinkedIn or other professional networking platforms to connect with current or former employees.

2. Highlight Your Troubleshooting Skills

Emphasize your experience in identifying and resolving die-related issues. Provide specific examples of successful troubleshooting.

- Use the STAR method (Situation, Task, Action, Result) to describe your problem-solving process.

- Quantify your results whenever possible, such as reducing downtime or increasing production yield.

3. Demonstrate Your Knowledge of Die Processes

Show that you have a strong understanding of die-making, die maintenance, and die operation.

- Discuss your experience with different types of dies, materials, and technologies.

- Explain how you ensure proper die maintenance and alignment to prevent problems.

4. Show Your Communication and Teamwork Skills

Die Trouble Shooters work closely with operators, engineers, and other team members. Highlight your ability to communicate effectively and collaborate.

- Provide examples of how you have worked with others to solve complex problems.

- Discuss your approach to communicating technical information to non-technical personnel.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Die Trouble Shooter, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Die Trouble Shooter positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.