Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Jig Maker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Jig Maker so you can tailor your answers to impress potential employers.

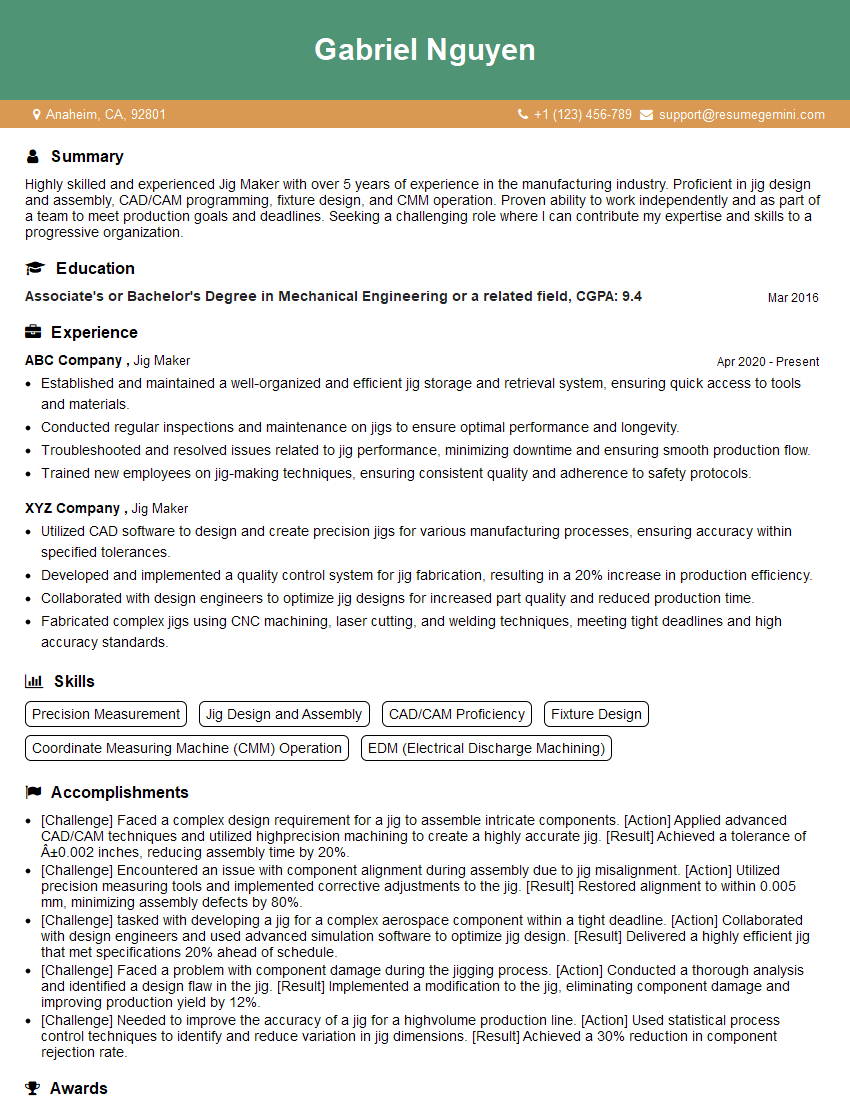

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Jig Maker

1. What are the key responsibilities of a Jig Maker?

As a Jig Maker, my key responsibilities include:

- Design and fabricate jigs and fixtures according to engineering specifications.

- Operate and maintain various machinery, including mills, lathes, and grinders.

- Inspect and test jigs and fixtures to ensure accuracy and functionality.

- Collaborate with engineers and other team members to develop and improve processes.

- Stay up-to-date on industry best practices and technologies.

2. What type of materials are commonly used in jig making?

Metals:

- Steel

- Aluminum

- Stainless Steel

Plastics:

- Acrylic

- Polycarbonate

- ABS

Composites:

- Fiberglass

- Carbon Fiber

3. What are the different types of jigs and fixtures used in manufacturing?

The different types of jigs and fixtures used in manufacturing include:

- Drill Jigs: Used to guide drilling operations.

- Milling Fixtures: Used to hold workpieces during milling operations.

- Assembly Fixtures: Used to hold and align components during assembly.

- Inspection Fixtures: Used to check the dimensions and tolerances of parts.

- Welding Fixtures: Used to hold and align components during welding.

4. What are the key considerations when designing a jig or fixture?

The key considerations when designing a jig or fixture include:

- Accuracy and Precision: The jig or fixture must be designed to hold the workpiece securely and accurately.

- Functionality: The jig or fixture must be easy to use and operate, and it must provide the necessary support and guidance for the manufacturing process.

- Cost: The jig or fixture must be cost-effective to manufacture and maintain.

- Safety: The jig or fixture must be designed with safety in mind, to protect the operator and the workpiece.

5. What are the common challenges faced by Jig Makers?

Common challenges faced by Jig Makers include:

- Meeting tight tolerances and specifications.

- Working with complex and delicate materials.

- Designing jigs and fixtures that are both functional and cost-effective.

- Keeping up with advancements in manufacturing technology.

- Ensuring the safety of themselves and others while operating machinery.

6. What is your experience in using CAD/CAM software?

I am proficient in using CAD/CAM software, such as SolidWorks and Mastercam, to design and create jigs and fixtures. I use CAD/CAM software to create 3D models of jigs and fixtures, generate toolpaths, and simulate the manufacturing process. This allows me to ensure that the jigs and fixtures I create are accurate, functional, and cost-effective.

7. What is your experience in working with CNC machines?

I have experience in working with a variety of CNC machines, including mills, lathes, and grinders. I use CNC machines to manufacture jigs and fixtures to precise tolerances and specifications. I am also familiar with programming CNC machines and troubleshooting any issues that may arise.

8. What are your strengths as a Jig Maker?

My strengths as a Jig Maker include:

- Strong technical skills in design, fabrication, and inspection.

- Proficient in using CAD/CAM software and CNC machines.

- Excellent attention to detail and accuracy.

- Ability to work independently and as part of a team.

- Excellent problem-solving and troubleshooting skills.

9. What are your weaknesses as a Jig Maker?

My weaknesses as a Jig Maker include:

- I am relatively new to the industry and have limited experience in some areas.

- I can sometimes be too detail-oriented, which can slow down the manufacturing process.

- I am not always the best at communicating my ideas to others.

I am actively working on improving my weaknesses and I am confident that I can overcome them with additional experience and training.

10. Why are you interested in this position?

I am interested in this position because I am passionate about Jig Making and I believe that I have the skills and experience to be successful in this role. I am excited about the opportunity to contribute my skills to your company and to learn from experienced Jig Makers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Jig Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Jig Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Jig Makers are responsible for designing, fabricating, and maintaining jigs and fixtures used in the manufacturing process. They ensure that the jigs and fixtures are accurate and meet the required specifications.

1. Design and Development

Jig Makers work closely with engineers and designers to create detailed drawings and specifications for jigs and fixtures.

- Develop concepts and design drawings.

- Analyze product specifications and determine appropriate jigging and fixturing requirements.

2. Fabrication

Jig Makers fabricate jigs and fixtures using a variety of methods, including machining, welding, and assembly.

- Select and use appropriate materials and equipment for fabrication.

- Follow detailed drawings and specifications to ensure accuracy and quality.

3. Maintenance and Repair

Jig Makers are responsible for maintaining and repairing jigs and fixtures to ensure their optimal performance.

- Inspect jigs and fixtures regularly to identify wear and tear.

- Perform maintenance and repairs to extend the lifespan of jigs and fixtures.

4. Quality Control

Jig Makers ensure that jigs and fixtures meet the required quality standards.

- Conduct quality checks and inspections throughout the fabrication process.

- Identify and correct any defects or deviations from specifications.

Interview Tips

Preparing for a Jig Maker interview requires a combination of technical knowledge and practical experience.

1. Research the Company

Gather information about the company’s products, services, and manufacturing processes. This will help you understand the context of the role and tailor your answers accordingly.

2. Practice Your Skills

Brush up on your technical skills, including machining, welding, and fabrication techniques. Be prepared to discuss your experience and proficiency in these areas.

3. Showcase Your Problem-Solving Abilities

Jig Makers often face challenges in design and fabrication. Prepare examples of situations where you successfully solved problems or improved processes.

4. Highlight Your Attention to Detail

Stress your ability to pay attention to even the smallest details. Explain how you ensure accuracy and precision in your work.

5. Prepare for Common Interview Questions

Review common interview questions related to Jig Making, such as:

- Tell me about your experience in designing and fabricating jigs and fixtures.

- What are the different types of jigs and fixtures you have worked with?

- How do you ensure the accuracy and quality of your work?

- Describe a situation where you faced a challenge in Jig Making and how you overcame it.

- Why are you interested in this position at our company?

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Jig Maker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.