Feeling lost in a sea of interview questions? Landed that dream interview for Tool and Die Maker Apprentice but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Tool and Die Maker Apprentice interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

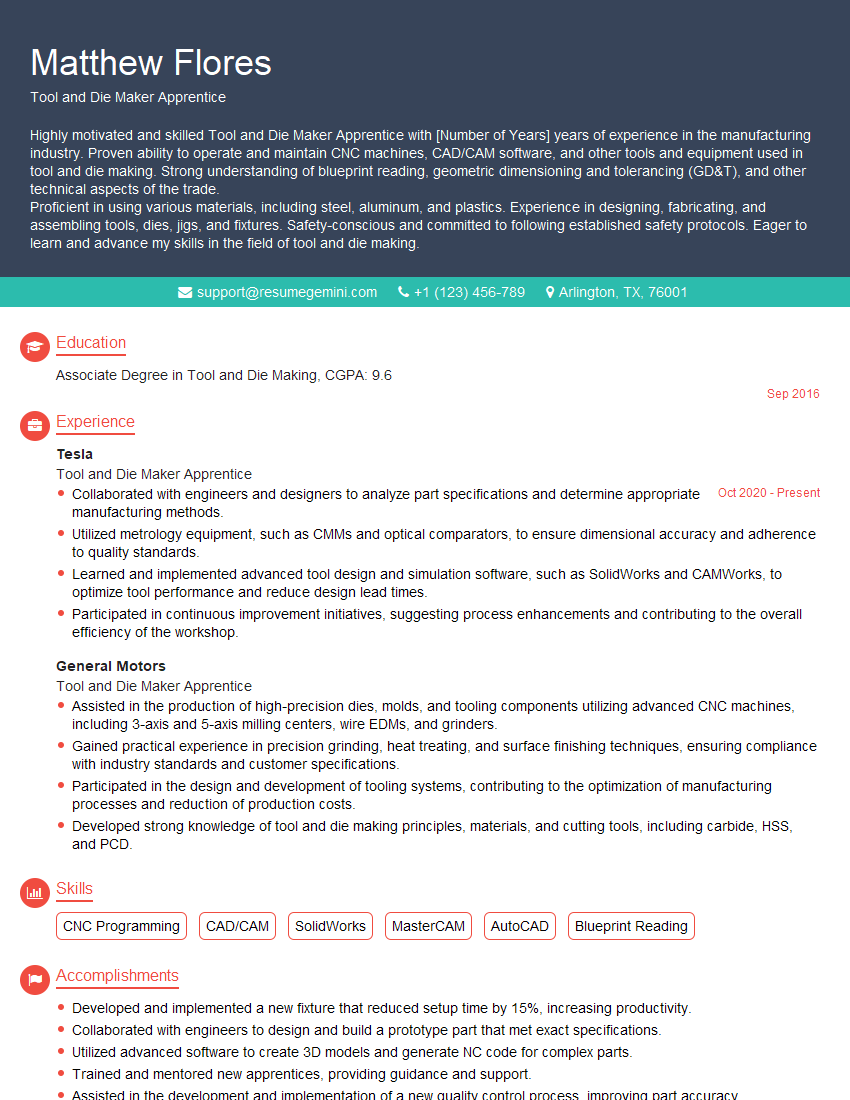

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tool and Die Maker Apprentice

1. Describe the process of heat treating a tool steel part?

Heat treating is a critical process in tool and die making, and involves controlled heating and cooling of steel to alter its properties. The steps involved are as follows:

- Annealing: The steel is heated to a specific temperature, usually above its critical temperature, and then slowly cooled to relieve internal stresses and soften the material.

- Hardening: The steel is heated to a temperature above its critical temperature and then rapidly cooled, typically by quenching in oil or water, to increase its hardness.

- Tempering: The hardened steel is reheated to a temperature below its critical temperature and then slowly cooled to reduce brittleness and improve toughness.

2. Explain the difference between a drill press and a milling machine?

Drill press

- Used for creating cylindrical holes

- Drill bit rotates and moves along the Z-axis

- Limited to vertical drilling operations

Milling machine

- Used for a wider range of machining operations, including milling, drilling, boring, and facing

- Rotating cutter moves along multiple axes (X, Y, Z)

- Allows for complex and precise machining

3. What are the different types of grinders used in tool and die making?

- Surface grinder: Used for precision grinding of flat surfaces

- Cylindrical grinder: Used for grinding cylindrical parts, such as shafts

- Internal grinder: Used for grinding the inside of holes

- Tool and cutter grinder: Used for sharpening cutting tools

- CBN grinder: Used for grinding hard materials, such as ceramics and composites

4. Describe the process of EDM (Electrical Discharge Machining)?

- A non-contact machining process that uses electrical discharges to erode material

- An electrode is used to create a spark gap with the workpiece

- The spark generates intense heat, which melts and vaporizes the material, creating the desired shape

- Used for machining complex shapes and hard materials

5. What are the different types of materials used in tool and die making?

- Tool steels: Used for cutting tools and dies due to their high hardness and wear resistance

- Alloy steels: Used for structural components due to their strength and toughness

- Plastics: Used for molds and fixtures due to their low cost and easy machinability

- Ceramics: Used for cutting tools and wear-resistant applications due to their high hardness and toughness

- Composites: Used for lightweight and high-strength applications

6. Describe the process of wire EDM (Wire Electrical Discharge Machining)?

- A specialized EDM process that uses a thin wire electrode to cut intricate shapes

- The wire is continuously fed through the workpiece, creating a narrow kerf

- Used for machining complex and precise contours

- Commonly used in the aerospace and medical industries

7. What are the different types of measuring tools used in tool and die making?

- Calipers: Used for measuring distances, diameters, and depths

- Micrometers: Used for precise measurements of small dimensions

- Dial indicators: Used for measuring small displacements and surface irregularities

- Height gauges: Used for measuring heights and depths

- Coordinate measuring machines (CMMs): Used for highly precise measurements of complex shapes

8. Describe the process of CNC (Computer Numerical Control) machining?

- A computer-controlled machining process that uses a cutting tool to remove material from a workpiece

- The cutting tool follows a programmed path defined by a CAD (Computer-Aided Design) file

- Used for high-precision and repeatable machining operations

- Reduces manual labor and improves accuracy

9. What are the different types of CNC machines used in tool and die making?

- Mills: Used for milling, drilling, and boring operations

- Lathes: Used for turning, facing, and threading operations

- EDM machines: Used for electrical discharge machining

- Waterjet cutters: Used for cutting a wide range of materials using a high-pressure water jet

- Laser cutters: Used for cutting and engraving using a focused laser beam

10. Describe the importance of quality control in tool and die making?

- Ensures that tools and dies meet the required specifications and tolerances

- Prevents defects and ensures the production of high-quality parts

- Involves regular inspections, measurements, and testing

- Helps reduce production costs by minimizing scrap and rework

- Maintains customer satisfaction and reputation

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tool and Die Maker Apprentice.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tool and Die Maker Apprentice‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tool and Die Maker Apprentices assist in the creation and maintenance of tools and dies used in the manufacturing process. They work under the supervision of experienced Tool and Die Makers, learning the trade and developing the skills necessary to become fully qualified.

1. Assist in the design and development of tools and dies

This may involve working with engineers and designers to create blueprints and specifications, or using computer-aided design (CAD) software to create 3D models of the tools and dies.

- Study blueprints and specifications to understand the design and function of tools and dies.

- Assist in the development of new tools and dies by providing feedback and suggestions.

2. Assist in the construction and assembly of tools and dies

This may involve using a variety of machine tools, such as lathes, mills, and grinders, to create the individual components of the tools and dies. It may also involve assembling the components into a finished product.

- Use machine tools to create the individual components of tools and dies, such as punches, dies, and molds.

- Assemble the components into a finished product, ensuring that all parts fit together properly.

3. Assist in the maintenance and repair of tools and dies

This may involve inspecting tools and dies for wear and tear, and making repairs as necessary. It may also involve sharpening or replacing cutting tools.

- Inspect tools and dies for wear and tear, and make repairs as necessary.

- Sharpen or replace cutting tools to ensure that they are functioning properly.

4. Assist in the operation of tools and dies

This may involve setting up the tools and dies in a press, and operating the press to produce parts. It may also involve monitoring the operation of the tools and dies to ensure that they are producing parts to the required specifications.

- Set up tools and dies in a press, and operate the press to produce parts.

- Monitor the operation of the tools and dies to ensure that they are producing parts to the required specifications.

Interview Tips

Preparing for an interview for a Tool and Die Maker Apprenticeship can be daunting, but there are several steps you can take to improve your chances of success. Here are a few tips to help you prepare:

1. Research the company and the position

Take some time to learn about the company you’re applying to and the specific position you’re interested in. This will help you understand the company’s culture and the requirements of the job, and it will also give you something to talk about in the interview.

- Visit the company’s website to learn about their history, products, and services.

- Read industry publications and news articles to learn about the latest trends in the tool and die making industry.

2. Practice your answers to common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Think about your strengths and weaknesses, and how they relate to the requirements of the job.

- Prepare a brief overview of your experience and qualifications, and be ready to discuss your skills and abilities.

3. Be prepared to talk about your experience with tools and machinery

Even if you don’t have any formal experience as a Tool and Die Maker, you may have some experience with tools and machinery that you can talk about in the interview. This could include experience working on cars, building projects, or even using power tools around the house.

- Highlight any experience you have with using machine tools, such as lathes, mills, and grinders.

- Describe any projects you’ve worked on that involved the use of tools and machinery.

4. Be enthusiastic and positive

Interviewers are looking for candidates who are enthusiastic about the tool and die making trade and who are eager to learn. Show your passion for the trade by asking thoughtful questions about the apprenticeship program and the company’s products and services.

- Express your interest in the apprenticeship program and the tool and die making trade.

- Ask questions about the company’s products and services to show that you’re interested in the business.

Next Step:

Now that you’re armed with the knowledge of Tool and Die Maker Apprentice interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Tool and Die Maker Apprentice positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini