Are you gearing up for a career in Acetylene Cutter? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Acetylene Cutter and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

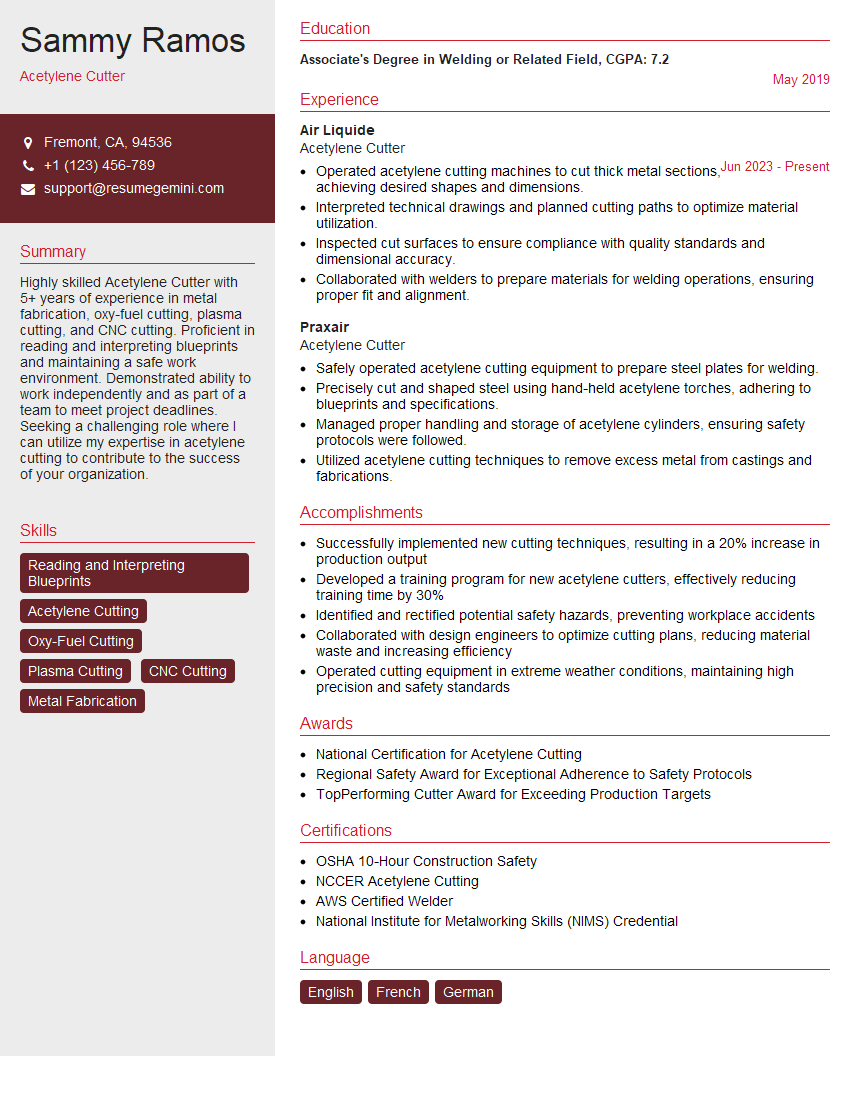

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Acetylene Cutter

1. Describe the process of oxy-fuel cutting and explain its principles.

- Oxy-fuel cutting involves using a focused stream of oxygen to burn through metal, resulting in a narrow and clean cut.

- The process requires three main components: fuel gas (usually acetylene), oxygen, and a cutting torch.

- The acetylene and oxygen gases are mixed in a torch to create a flame that heats the metal to its ignition temperature.

- Once the metal reaches the ignition point, the oxygen supply is increased, causing a rapid oxidation process that cuts through the metal.

2. What are the different types of cutting tips and how do you choose the appropriate one for a given task?

- Cutting tips are categorized based on the thickness of the metal being cut.

- Smaller tips are used for thin metal, while larger tips are used for thicker metal.

- Selecting the correct tip is crucial for achieving a clean and efficient cut.

- Using an incorrect tip can result in excessive slag formation, poor kerf quality, or damage to the torch.

3. How do you set up and prepare an acetylene cutting torch for operation?

- Before using the torch, it is essential to check that all components are in good working condition.

- Inspect hoses for leaks, and ensure that regulators and gauges are functioning correctly.

- Connect the torch to the gas supply and adjust the gas pressures according to the manufacturer’s specifications.

- Light the torch and adjust the flame to a neutral setting to prevent flashback or excessive carbonization.

4. Describe the safety precautions and operating procedures to be followed when using an acetylene cutting torch.

- Acetylene is a highly flammable gas, so it is crucial to follow proper safety measures.

- Always wear appropriate personal protective equipment, including gloves, eye protection, and flame-resistant clothing.

- Ensure that the work area is well-ventilated to prevent the accumulation of flammable gases.

- Never use the torch near flammable materials or in areas with potential ignition sources.

5. How do you maintain and troubleshoot an acetylene cutting torch to ensure optimal performance?

- Regular maintenance is essential to keep the torch operating efficiently and safely.

- Inspect the torch regularly for leaks, blockages, and worn-out parts.

- Clean the torch nozzle regularly to prevent clogging and ensure a smooth gas flow.

- Troubleshoot common issues such as flashback, poor flame quality, or insufficient cutting power by checking gas pressures, cleaning the torch, or replacing worn-out parts.

6. What are the different cutting techniques used with an acetylene torch, and when is each technique most appropriate?

- There are several cutting techniques, including straight cutting, bevel cutting, piercing, and gouging.

- Straight cutting is used for cutting straight lines in metal.

- Bevel cutting is used to create angled cuts, such as for welding preparation.

- Piercing is used to create holes in metal.

- Gouging is used to remove unwanted material from metal surfaces.

- The choice of technique depends on the specific task and the desired outcome.

7. How do you inspect a cut surface to assess the quality of the cut and identify any potential defects?

- Inspecting the cut surface is crucial to ensure that the cut meets the desired specifications and is free from defects.

- Check the cut for smoothness, squareness, and the absence of slag or dross.

- Any irregularities in the cut surface can indicate potential problems with the cutting process or equipment.

- Identifying defects promptly allows for corrective action to be taken, preventing further issues.

8. Describe the metallurgy of the cutting process, including the effects of heat, oxygen, and carbon content on the cut surface.

Metallurgy of the cutting process

- The cutting process involves complex metallurgical reactions that influence the properties of the cut surface.

- Heat causes the metal to soften and become more pliable, facilitating the cutting action.

- Oxygen reacts with the metal, forming iron oxides (slag) that are expelled from the cut.

- Carbon content affects the hardness and strength of the cut surface.

Effects on the cut surface

- Excessive heat can lead to hardening of the cut surface, making it brittle.

- Insufficient oxygen can result in incomplete oxidation, leaving slag on the cut surface.

- High carbon content can make the cut surface harder and more resistant to wear.

9. What are the different types of oxy-fuel gases used for cutting, and how do their properties affect the cutting process?

- Acetylene is the most commonly used fuel gas for oxy-fuel cutting due to its high flame temperature and rapid cutting speed.

- Other fuel gases include propane, natural gas, and hydrogen, each with its own advantages and disadvantages.

- The choice of fuel gas can impact the cutting speed, flame characteristics, and overall efficiency of the process.

10. Discuss the role of preheating and postheating in oxy-fuel cutting, and explain how these techniques can improve the quality of the cut.

Preheating

- Preheating the metal before cutting helps to reduce thermal shock and warping.

- It allows the metal to reach a more uniform temperature, making the cutting process smoother and more efficient.

Postheating

- Postheating the cut surface after cutting helps to relieve stresses and prevent cracking.

- It also reduces the hardness of the cut zone, making it more ductile and less susceptible to brittle fracture.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Acetylene Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Acetylene Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Acetylene Cutters are responsible for cutting and shaping metals using an acetylene torch, ensuring precision and adherence to specifications. Here are the key job responsibilities:

1. Cutting and Shaping Metals

Using an acetylene torch, acetylene cutters precisely cut and shape metal pieces as per blueprints and specifications,

- Employing proper cutting techniques to achieve clean and accurate cuts

- Adjusting torch settings, such as gas pressure and flame type, to suit different metal types and thicknesses

2. Preparing and Inspecting Workpieces

Before cutting, acetylene cutters prepare workpieces by removing burrs, rust, or other obstructions that may affect the cut quality.

- Inspecting workpieces to ensure they meet specifications and identifying any potential defects

- Marking cutting lines clearly on the workpiece using appropriate tools

3. Maintaining Equipment

Acetylene cutters are responsible for maintaining their equipment to ensure safety and efficient operation.

- Performing regular inspections of torches, hoses, and regulators to identify any damage or wear

- Cleaning and maintaining equipment as per manufacturer’s guidelines to prevent malfunctions

4. Safety Compliance

Acetylene cutters adhere to strict safety regulations to minimize risks associated with their work.

- Wearing appropriate personal protective equipment (PPE), including gloves, goggles, and flame-resistant clothing

- Following established safety procedures for handling and storing acetylene gas and equipment

Interview Tips

To ace an interview for an Acetylene Cutter position, it’s essential to prepare thoroughly. Here are some helpful tips:

1. Research the Industry

Familiarize yourself with the specific industry where acetylene cutting is commonly used, such as construction, fabrication, or manufacturing.

- Learn about different types of metals and their properties to demonstrate your knowledge of the materials you’ll be working with.

- Research common applications of acetylene cutting to showcase your understanding of its practical uses.

2. Practice Your Skills

If possible, practice your acetylene cutting skills to gain confidence and improve your technique.

- Attend workshops or training sessions to enhance your proficiency.

- Seek opportunities to practice on scrap metal or non-critical projects to improve your accuracy and efficiency.

3. Study Safety Protocols

Emphasize your understanding of safety protocols related to acetylene cutting to demonstrate your commitment to a safe work environment.

- Review OSHA or industry-specific safety guidelines for acetylene cutting.

- Prepare examples of how you ensure your own safety and that of others while operating acetylene cutting equipment.

4. Highlight Your Experience

Tailor your resume and interview answers to highlight your relevant experience in acetylene cutting or related fields.

- Quantify your accomplishments whenever possible, providing specific examples of projects or tasks where you successfully used acetylene cutting.

- Emphasize your ability to work independently and as part of a team, as both may be required in this role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Acetylene Cutter interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.