Are you gearing up for an interview for a Arc Cutter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Arc Cutter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

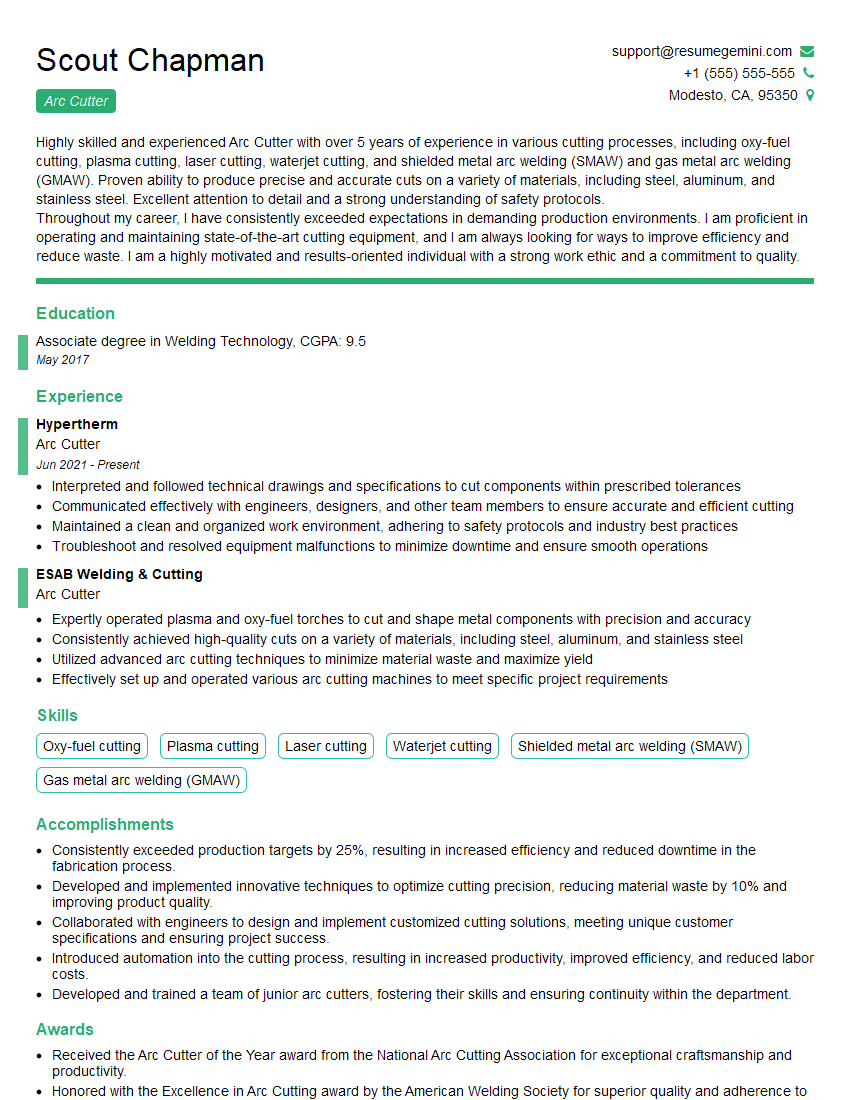

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Arc Cutter

1. Describe the general arc cutting process?

The arc cutting process involves using an electric arc to melt and sever metal. It is a versatile process that can be used to cut a wide variety of metals, including steel, stainless steel, aluminum, and copper.

- The process begins by establishing an electric arc between a consumable electrode and the metal workpiece.

- The arc melts the metal, and a jet of compressed air is used to blow away the molten metal, creating a cut.

- The speed and accuracy of the cut are controlled by the operator, who moves the torch along the desired cutting line.

2. How do you select the correct cutting speed for arc cutting?

- The correct cutting speed for arc cutting depends on a number of factors, including the thickness of the metal, the type of metal, and the desired cut quality.

- In general, thicker metals require slower cutting speeds, while thinner metals can be cut at higher speeds.

- Harder metals, such as stainless steel, also require slower cutting speeds than softer metals, such as aluminum.

3. What are the different types of arc cutting torches?

- There are two main types of arc cutting torches: air plasma torches and oxygen plasma torches.

- Air plasma torches use compressed air as the plasma gas, while oxygen plasma torches use oxygen.

- Oxygen plasma torches produce a hotter plasma than air plasma torches, which allows them to cut through thicker metals.

- Air plasma torches are less expensive and easier to operate than oxygen plasma torches.

4. What are the safety precautions that must be taken when arc cutting?

- Arc cutting can be a hazardous process, so it is important to take proper safety precautions.

- These precautions include wearing appropriate personal protective equipment, such as a welding helmet, gloves, and a respirator.

- It is also important to ensure that the work area is well-ventilated and that there are no flammable materials nearby.

5. What are the common defects that can occur during arc cutting?

- There are several common defects that can occur during arc cutting, including undercut, slag inclusions, and warping.

- Undercut is a condition where the metal is melted away from the edge of the cut, leaving a notch.

- Slag inclusions are pieces of molten metal that become trapped in the cut.

- Warping is a condition where the metal bends or twists out of shape during the cutting process.

6. How do you troubleshoot common problems with arc cutting equipment?

- Troubleshooting common problems with arc cutting equipment requires a systematic approach.

- First, it is important to identify the problem and then determine the possible causes.

- Once the possible causes have been identified, they can be tested one at a time until the problem is resolved.

7. What are the different applications of arc cutting?

- Arc cutting is used in a wide variety of applications, including shipbuilding, automotive manufacturing, and construction.

- It is used to cut a variety of metals, including steel, stainless steel, aluminum, and copper.

- Arc cutting can be used to cut straight lines, curves, and bevels.

8. What is the difference between plasma arc cutting and oxy-fuel cutting?

- Plasma arc cutting and oxy-fuel cutting are two different metal cutting processes that use different gases and temperatures to cut through metal.

- Plasma arc cutting uses a plasma torch to create a high-temperature plasma that melts the metal, while oxy-fuel cutting uses a mixture of oxygen and fuel gas to create a flame that cuts through the metal.

- Plasma arc cutting is faster and more precise than oxy-fuel cutting, but it is also more expensive.

9. What are the advantages of using a CNC (computer numerical control) arc cutting machine?

- CNC arc cutting machines offer a number of advantages over manual arc cutting machines, including increased accuracy, precision, and repeatability.

- CNC arc cutting machines are also faster than manual arc cutting machines, and they can be used to cut complex shapes and patterns.

10. What are the latest trends in arc cutting technology?

- The latest trends in arc cutting technology include the development of new plasma torches and power supplies.

- These new technologies are making arc cutting faster, more precise, and more versatile than ever before.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Arc Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Arc Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Arc Cutters are responsible for operating arc cutting equipment to cut metal objects. They are also responsible for setting up and maintaining their equipment, and for following safety procedures.

1. Operate arc cutting equipment

Arc Cutters use handheld or stationary arc cutting equipment to cut metal objects. They must be able to control the cutting torch and guide it accurately along the desired cutting path.

- Use handheld or stationary arc cutting equipment

- Control the cutting torch and guide it accurately

2. Set up and maintain equipment

Arc Cutters are responsible for setting up and maintaining their own equipment. This includes tasks such as installing and adjusting cutting tips, cleaning the equipment, and lubricating the moving parts.

- Install and adjust cutting tips

- Clean the equipment

- Lubricate the moving parts

3. Follow safety procedures

Arc Cutting is a dangerous job. Arc Cutters must follow all safety procedures to protect themselves and others from injury.

- Wear appropriate safety gear

- Use proper cutting techniques

- Be aware of the surroundings

Interview Tips

Preparing for an interview for an Arc Cutter position can be a daunting task. However, by following these tips, you can increase your chances of success.

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you are applying for. This will give you a better understanding of the company’s culture and the specific requirements of the job.

- Visit the company’s website

- Read articles about the company

- Talk to people who work at the company

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked. By practicing your answers to these questions, you can increase your confidence and deliver more polished responses.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

3. Be prepared to talk about your experience

The interviewer will want to know about your experience as an Arc Cutter. Be prepared to talk about your skills and abilities, and to provide examples of your work.

- Describe your experience operating arc cutting equipment.

- Explain how you set up and maintain your equipment.

- Discuss your safety procedures.

4. Be enthusiastic and professional

Make a good impression on the interviewer by being enthusiastic and professional. Dress appropriately, arrive on time for your interview, and be polite and respectful to everyone you meet.

- Dress appropriately

- Arrive on time for your interview

- Be polite and respectful

Next Step:

Now that you’re armed with the knowledge of Arc Cutter interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Arc Cutter positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini