Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Atomic Welder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

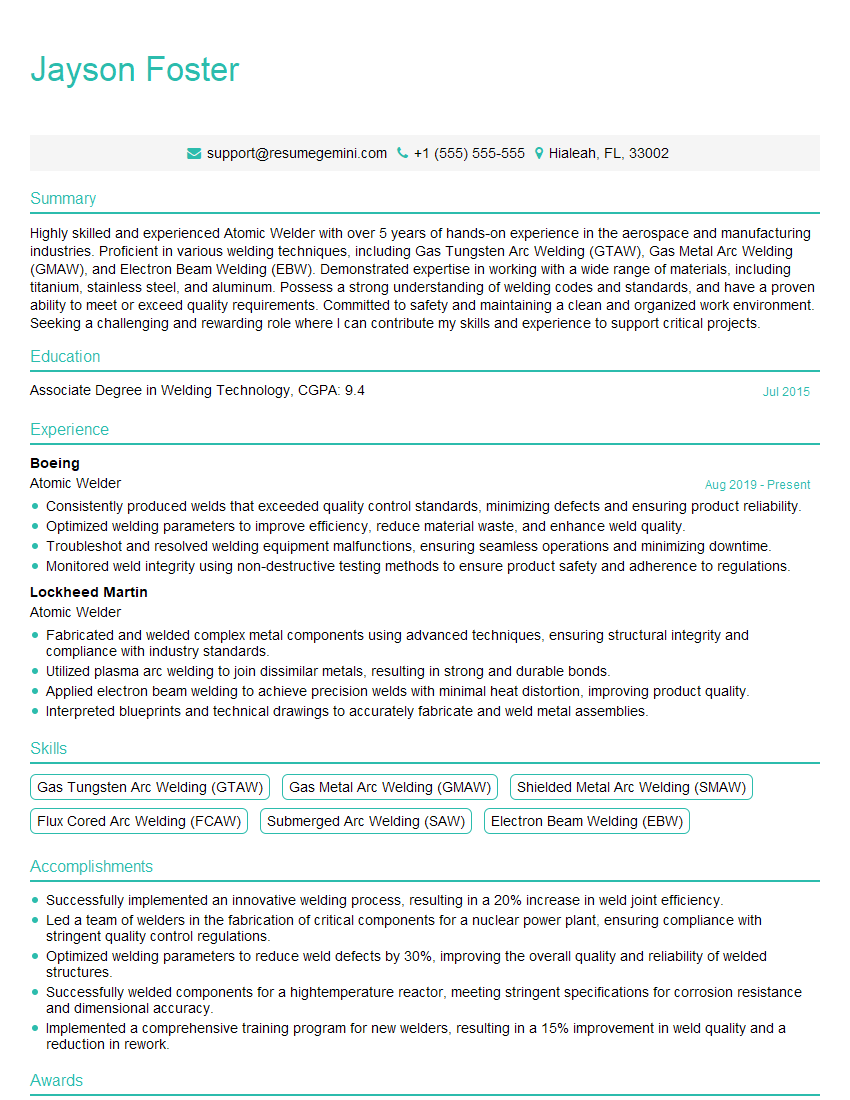

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Atomic Welder

1. Describe the process of welding dissimilar metals, such as steel and aluminum?

When welding dissimilar metals, it is important to consider the differences in their properties, such as their melting points and thermal conductivity. Special techniques and filler materials may be required to ensure a strong and durable weld. The process may involve preheating one of the metals to reduce the risk of cracking, and using a specialized welding technique such as friction welding or ultrasonic welding.

2. What are the different types of welding joints?

There are various types of welding joints, each designed for specific applications. Some common types include:

- Butt joint: The edges of the two pieces of metal are aligned and fused together.

- Edge joint: The edges of the two pieces of metal are overlapped and fused together.

- Corner joint: The two pieces of metal are joined at a 90-degree angle and fused together.

- T-joint: One piece of metal is perpendicular to the other, and they are fused together.

3. What are the different types of welding machines?

There are different types of welding machines available, each with its own advantages and applications. Some common types include:

- Arc welding machines: These machines use an electric arc to melt the metal and create a weld.

- Gas welding machines: These machines use a combustible gas to create a flame that melts the metal and creates a weld.

- Laser welding machines: These machines use a laser beam to melt the metal and create a weld.

4. What are the safety precautions that should be taken when welding?

Welding can be a hazardous process, so it is important to take proper safety precautions to minimize the risk of injury. Some important precautions include:

- Wearing appropriate protective clothing, including a welding helmet, gloves, and fire-resistant clothing.

- Ensuring that the work area is well-ventilated to prevent the inhalation of harmful fumes.

- Inspecting equipment regularly and ensuring that it is in good working order.

- Following proper welding techniques and procedures to minimize the risk of accidents.

5. What are the different types of welding defects?

There are various types of welding defects that can occur, which can affect the strength and integrity of the weld. Some common types of defects include:

- Porosity: The presence of gas bubbles or voids in the weld.

- Cracking: The formation of cracks in the weld metal.

- Undercut: A groove or notch formed along the edge of the weld.

- Cold lap: A condition where the weld metal does not properly fuse with the base metal.

6. How do you ensure the quality of a weld?

To ensure the quality of a weld, it is important to follow proper welding techniques and procedures, and to inspect the weld after it is completed. Some common quality control measures include:

- Visual inspection: Inspecting the weld for any visible defects, such as cracks, porosity, or undercut.

- Non-destructive testing: Using methods such as radiography or ultrasonic testing to detect internal defects.

- Destructive testing: Testing the weld by applying a load to it to determine its strength and integrity.

7. What are the different welding codes and standards?

There are various welding codes and standards that have been developed to ensure the quality and safety of welds. These codes and standards specify the requirements for welding materials, welding procedures, and welder qualifications. Some common welding codes and standards include:

- AWS D1.1: Structural Welding Code – Steel

- AWS D1.2: Structural Welding Code – Aluminum

- ASME Boiler and Pressure Vessel Code

- ISO 3834: Quality Requirements for Welding, Brazing, and Soldering of Metallic Materials

8. What is the importance of welding in various industries?

Welding plays a vital role in various industries, including:

- Construction: Welding is used to join structural components in buildings, bridges, and other structures.

- Manufacturing: Welding is used to fabricate and assemble products such as automobiles, aircraft, and machinery.

- Repair and maintenance: Welding is used to repair and maintain equipment, machinery, and other metal structures.

- Art and sculpture: Welding is used to create artistic sculptures and decorative pieces.

9. What are the challenges and advancements in the field of welding?

The field of welding is constantly evolving, with new challenges and advancements emerging. Some of the current challenges include:

- Developing welding techniques for new materials, such as composites and high-strength steels.

- Improving the efficiency and automation of welding processes.

- Reducing the environmental impact of welding.

Some of the recent advancements in welding include:

- The development of new welding technologies, such as laser welding and friction welding.

- The use of robotics and automation in welding processes.

- The development of new welding materials and consumables.

10. How do you stay updated with the latest developments in the welding industry?

To stay updated with the latest developments in the welding industry, I regularly engage in the following activities:

- Attending welding conferences and workshops.

- Reading welding industry publications and journals.

- Participating in online welding forums and discussion groups.

- Networking with other welding professionals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Atomic Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Atomic Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Atomic Welders are highly skilled professionals responsible for joining and fabricating metal components using specialized atomic welding techniques. Their primary duties include:

1. Welding Operations

Performing various welding tasks, such as shielded metal arc (SMAW), gas metal arc (GMAW), and gas tungsten arc (GTAW).

- Maintaining precise weld parameters to ensure the highest quality.

- Adhering to safety protocols and regulations.

2. Inspection and Testing

Conducting visual inspections and non-destructive testing (NDT) to evaluate weld quality.

- Identifying and resolving defects or irregularities.

- Ensuring compliance with specifications and industry standards.

3. Equipment Management

Properly handling, setting up, and operating welding equipment.

- Maintaining and calibrating equipment for optimal performance.

- Following maintenance schedules and troubleshooting common issues.

4. Collaboration and Communication

Collaborating with engineers, fabricators, and other team members to ensure project success.

- Effectively communicating technical information and progress updates.

- Participating in problem-solving and decision-making processes.

Interview Tips

To ace an Atomic Welder interview, it’s crucial to:

1. Research the Company and Industry

Thoroughly research the company’s background, values, current projects, and industry trends. This demonstrates your interest and enthusiasm for the role.

- Practice answering questions about your knowledge of the industry and its challenges.

- Highlight any experience you have working on similar projects or using specialized equipment.

2. Emphasize Your Skills and Experience

Clearly showcase your technical skills, certifications, and experience in atomic welding techniques. Quantify your accomplishments and provide specific examples.

- Discuss your proficiency in various welding methods and the types of materials you’ve worked with.

- Highlight your expertise in quality control, safety procedures, and troubleshooting.

3. Prepare for Technical Questions

Anticipate technical questions related to welding processes, equipment, and industry standards. Practice answering them confidently and accurately.

- Review common welding terminology and concepts.

- Study the principles of atomic welding and its applications.

4. Demonstrate Your Problem-Solving Abilities

Highlight your problem-solving skills and ability to handle challenges on the job. Provide examples of how you’ve overcome obstacles or resolved technical issues.

- Describe situations where you identified and corrected weld defects.

- Explain how you troubleshoot and resolve equipment malfunctions.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Atomic Welder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.