Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Blade Worker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

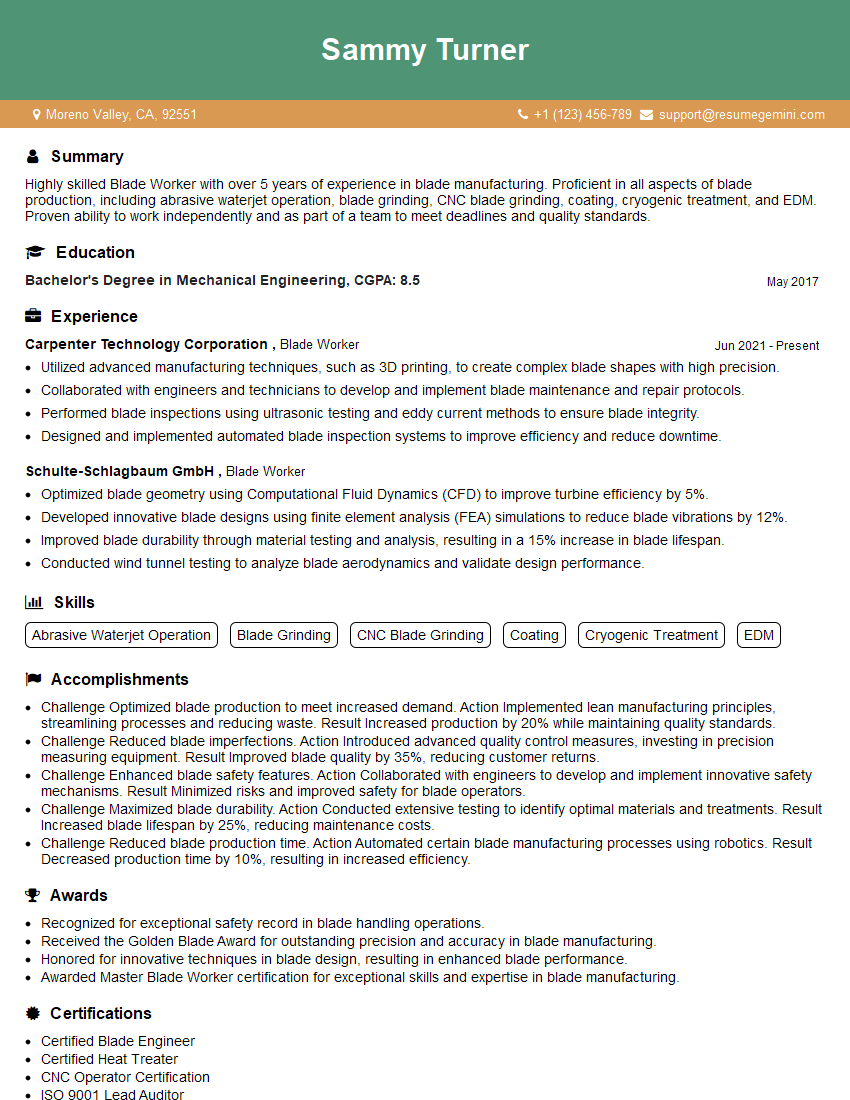

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Blade Worker

1. What are the key responsibilities of a Blade Worker?

- Sharpen and maintain blades used in various industrial applications, ensuring they meet specified tolerances and performance requirements.

- Inspect blades for damage, wear, and other defects, and determine appropriate repair or replacement procedures.

- Use specialized equipment and techniques to grind, hone, and polish blades to achieve optimal cutting performance.

- Set up and operate blade grinding machines, following established procedures and safety guidelines.

- Maintain a clean and organized work area, ensuring compliance with safety regulations and industry standards.

2. What types of blades do you have experience working with?

- Industrial knives used in various applications such as paper cutting, food processing, and metalworking.

- Circular saw blades for woodworking, metalworking, and construction.

- Band saw blades used in cutting a wide range of materials, including wood, metal, and plastics.

- Milling cutter blades for machining operations in CNC machines.

- Shear blades used in metalworking and other industrial processes.

3. What is your understanding of blade geometry and its impact on cutting performance?

- Blade angle: The angle at which the blade meets the cutting material, affecting factors such as cutting force, chip formation, and surface finish.

- Rake angle: The angle of the blade’s cutting edge relative to the surface being cut, influencing cutting efficiency and tool life.

- Clearance angle: The angle between the blade’s back surface and the cutting surface, providing clearance to prevent rubbing and excessive friction.

- Relief angle: The angle between the blade’s cutting edge and its flank surface, reducing friction and improving cutting performance.

4. How do you ensure that blades meet the required specifications and tolerances?

- Use precision measuring instruments such as calipers, micrometers, and blade gauges to accurately measure blade dimensions and angles.

- Follow established quality control procedures to verify that blades meet specified tolerances and performance criteria.

- Make necessary adjustments to grinding and honing processes based on inspection results.

- Maintain records of blade measurements and inspection results for quality assurance and traceability.

5. What are some common challenges you have encountered in blade sharpening and how did you overcome them?

- Damaged blades: Assess the extent of damage and determine if repair or replacement is necessary. Use appropriate techniques to restore the blade’s cutting edge and ensure optimal performance.

- Difficult-to-sharpen materials: Employ specialized grinding wheels and honing techniques to effectively sharpen blades made of hard or brittle materials.

- Precise tolerances: Utilize precision measuring instruments and carefully adjust grinding and honing processes to achieve extremely tight tolerances.

- Safety concerns: Adhere to established safety protocols, use appropriate personal protective equipment, and maintain a clean and organized work area to minimize risks.

6. What is your experience with using different types of grinding and honing equipment?

- Surface grinders: Used for precision grinding of flat surfaces and edges.

- Cylindrical grinders: For grinding cylindrical surfaces such as shafts and pins.

- Tool and cutter grinders: Specifically designed for sharpening cutting tools, including blades.

- Honing machines: Used to refine the cutting edge of blades, improving sharpness and reducing surface roughness.

7. What are the safety precautions you take when working with sharp blades?

- Always wear appropriate personal protective equipment, including safety glasses, gloves, and a protective apron.

- Ensure that grinding and honing equipment is properly guarded and maintained.

- Handle blades with care, using proper techniques to avoid cuts and injuries.

- Store blades safely in designated areas to prevent accidental contact.

- Be aware of surroundings and potential hazards, and take necessary precautions to prevent accidents.

8. How do you stay updated with the latest advancements in blade sharpening techniques and technologies?

- Attend industry conferences and workshops to learn about new developments.

- Read trade publications and technical journals to stay informed about best practices and emerging technologies.

- Network with other blade workers and professionals in the industry to exchange knowledge and experiences.

- Seek opportunities for training and professional development to enhance skills and competencies.

9. What makes you a suitable candidate for this Blade Worker position?

- Proven experience in blade sharpening and maintenance, with a deep understanding of blade geometry and its impact on cutting performance.

- Expertise in using various grinding and honing equipment to achieve precise tolerances and optimal blade sharpness.

- Strong attention to detail, accuracy, and quality assurance, ensuring that blades meet the required specifications.

- Commitment to safety and adherence to established protocols, creating a safe and efficient work environment.

- Excellent problem-solving skills and ability to overcome challenges in blade sharpening and repair.

10. Do you have any questions for us about the Blade Worker position or the company?

- Can you elaborate on the specific industries or applications that your company serves?

- What are the company’s expectations for the Blade Worker role in terms of productivity and quality standards?

- Are there opportunities for professional development and advancement within the company for Blade Workers?

- How does the company ensure that its blade sharpening processes align with industry best practices and technological advancements?

- What are the company’s safety policies and procedures, and how are they enforced in the workplace?

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Blade Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Blade Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Blade Workers play a vital role in various industries by operating, maintaining, and repairing a wide range of cutting tools and machines. Their key responsibilities include:

1. Fabrication and Repair

Blade Workers fabricate and repair blades used in cutting tools, such as knives, shears, and saws. They grind, shape, and heat-treat the blades to achieve the desired sharpness and durability.

- Grind and sharpen blades using specialized equipment to create precise cutting edges.

- Repair damaged or worn blades by welding, forging, or resurfacing them to restore their functionality.

2. Machine Operation and Maintenance

Blade Workers operate and maintain various machines used in the blade-making process. They calibrate and adjust these machines to ensure optimal performance and safety.

- Operate grinding machines, lathes, and other equipment to shape and finish blades.

- Maintain and repair machines to prevent breakdowns and ensure efficient operations.

3. Quality Control and Troubleshooting

Blade Workers ensure that blades meet quality standards by conducting inspections and tests throughout the production process. They troubleshoot any issues that arise and implement corrective measures.

- Inspect blades for defects, such as cracks, burrs, or uneven surfaces.

- Troubleshoot and resolve machine or production issues to minimize downtime and maintain efficiency.

4. Safety and Compliance

Blade Workers prioritize safety and comply with industry regulations. They follow proper safety protocols and wear appropriate protective gear.

- Adhere to safety guidelines and regulations to prevent accidents and injuries.

- Wear protective clothing, such as gloves, safety glasses, and earplugs, to minimize hazards.

Interview Tips

To ace an interview for a Blade Worker position, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and industry trends. This shows that you are genuinely interested in the role and have taken the time to understand the organization.

- Visit the company’s website and social media pages to gather information.

- Read industry publications and articles to stay updated on the latest advancements in blade technology.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills, such as grinding, welding, and machine operation. Quantify your experience and provide specific examples of projects where you have demonstrated these skills.

- Describe your proficiency in using specific equipment and software.

- Share experiences where you successfully repaired complex blade mechanisms or resolved production issues.

3. Demonstrate Safety Consciousness

Safety is paramount in blade working. Highlight your commitment to safety by describing your adherence to protocols and use of protective gear. Share examples of how you have prioritized safety in your previous roles.

- Explain your understanding of safety regulations and industry best practices.

- Provide examples of situations where you identified and mitigated potential hazards.

4. Prepare Questions

Asking thoughtful questions at the end of the interview demonstrates your engagement and interest in the position. Prepare questions that are specific to the role or company, such as:

- “What are the specific quality standards for blades produced by the company?”

- “How does the company ensure the safe operation and maintenance of blade-making machinery?”

5. Practice and Be Confident

Practice your answers to common interview questions. Focus on being clear, concise, and enthusiastic. Confidence and a positive attitude can make a significant impact on the interviewer’s perception of your suitability for the role.

- Rehearse your responses out loud to improve your delivery and reduce nervousness.

- Dress professionally and arrive on time for the interview, demonstrating your attention to detail and respect for the interviewer’s time.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Blade Worker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Blade Worker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.