Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Butt Welder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

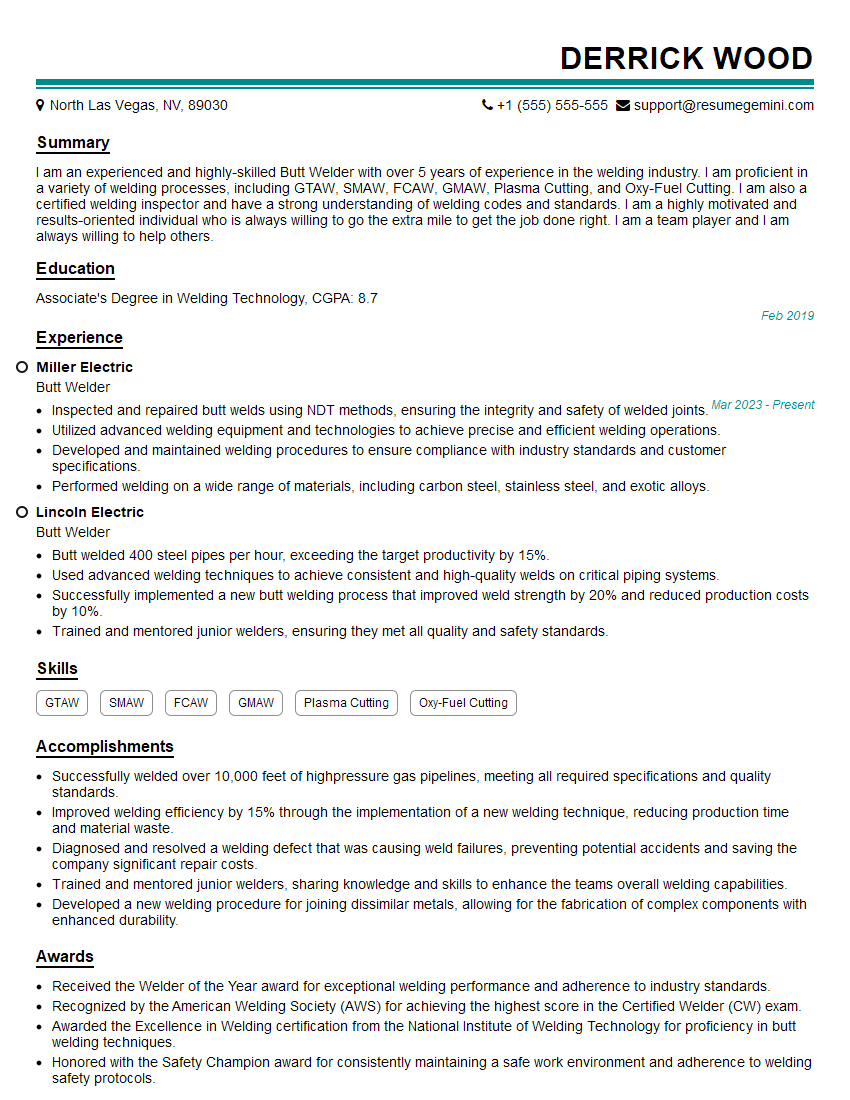

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Butt Welder

1. What is the process of butt welding?

Butt welding is a welding process that joins two pieces of metal by fusing them together at their ends. The edges of the two pieces of metal are first prepared by cleaning and squaring them. Then, the two pieces of metal are placed together with their edges in contact with each other. A welding torch or an electric arc is then used to heat the edges of the metals until they melt and fuse together.

2. What are the different types of butt welds?

Square Butt Weld

- A square butt weld is a weld in which the edges of the two pieces of metal are joined together in a straight line.

- It is the most common type of butt weld and is used in a wide variety of applications.

Bevel Butt Weld

- A bevel butt weld is a weld in which the edges of the two pieces of metal are beveled at an angle before they are joined together.

- This type of weld is used when the thickness of the metal is greater than 1/4 inch.

V-Butt Weld

- A V-butt weld is a weld in which the edges of the two pieces of metal are beveled at a 45-degree angle before they are joined together.

- This type of weld is used when the thickness of the metal is greater than 1/2 inch.

U-Butt Weld

- A U-butt weld is a weld in which the edges of the two pieces of metal are beveled at a 60-degree angle before they are joined together.

- This type of weld is used when the thickness of the metal is greater than 1 inch.

3. What are the advantages and disadvantages of butt welding?

Advantages

- Butt welding is a strong and durable welding process.

- It is relatively easy to learn and perform.

- It can be used to weld a wide variety of metals.

Disadvantages

- Butt welding can be slow and time-consuming.

- It can be difficult to weld thin metals.

- It can be difficult to weld metals that have different melting points.

4. What are the safety precautions that should be taken when butt welding?

- Wear appropriate safety gear, including a welding helmet, gloves, and apron.

- Make sure the work area is well-ventilated.

- Keep the welding torch or electric arc away from flammable materials.

- Do not weld on wet or oily surfaces.

- Allow the weld to cool before handling it.

5. What are some of the common defects that can occur in butt welds?

- Porosity

- Slag inclusions

- Lack of fusion

- Undercut

- Cracking

6. What are some of the factors that can affect the quality of a butt weld?

- The type of metal being welded

- The thickness of the metal being welded

- The welding process being used

- The skill of the welder

7. What are some of the applications of butt welding?

- Automotive

- Construction

- Manufacturing

- Shipbuilding

- Aerospace

8. What is the future of butt welding?

Butt welding is a well-established welding process that is expected to continue to be used in a wide variety of applications. However, there are some new technologies that are being developed that may challenge the dominance of butt welding in the future. These technologies include laser welding and friction stir welding.

9. What are your strengths and weaknesses as a butt welder?

I have been working as a butt welder for the past 5 years. I am proficient in all types of butt welding, including square butt welds, bevel butt welds, V-butt welds, and U-butt welds. I am also familiar with the different types of welding equipment and can troubleshoot and repair welding problems.

My strengths as a butt welder include my attention to detail, my ability to work independently, and my commitment to safety. I am also a quick learner and am always willing to try new things.

My weaknesses as a butt welder include my lack of experience with some of the newer welding technologies, such as laser welding and friction stir welding. I am also not as fast as some of the other welders in my shop.

10. What are your career goals?

My career goal is to become a welding supervisor. I would like to learn more about the different welding processes and how to manage a team of welders. I also want to develop my skills in welding inspection and quality control.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Butt Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Butt Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Butt Welder is responsible for welding metal pieces together using a butt welding machine. Key responsibilities include:

1. Welding Preparation

Prepares metal pieces for welding by cleaning, cutting, and shaping them to meet specifications.

2. Machine Operation

Sets up and operates butt welding machines to weld metal pieces according to specifications.

3. Quality Control

Inspects welded joints to ensure they meet quality standards and specifications.

4. Maintenance

Performs routine maintenance and repairs on welding machines and associated equipment.

5. Safety

Follows all safety procedures and regulations to ensure a safe work environment.

Interview Tips

To prepare for an interview for a Butt Welder position, consider the following tips:

1. Research the Company

Research the company and the specific industry to gain insights into their values, products, and services.

2. Practice Welding

Practice welding techniques and familiarize yourself with different types of welding equipment.

3. Highlight Safety

Emphasize your commitment to safety and knowledge of industry regulations.

4. Prepare Questions

Prepare thoughtful questions to ask the interviewer, demonstrating your interest and engagement.

5. Dress Professionally

Dress professionally and arrive on time for the interview.

6. Review Key Responsibilities

Review the key job responsibilities and be prepared to discuss how your skills align with them.

7. Practice Answering Common Questions

Practice answering common interview questions, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”

8. Showcase Certification

If applicable, highlight any certifications or training you have obtained in welding.

9. Prepare for Hands-on Assessment

In some cases, you may be asked to demonstrate your welding skills during the interview.

10. Be Yourself

Be yourself and demonstrate your passion for welding. Let the interviewer see your enthusiasm and willingness to learn.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Butt Welder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.